Mecanoquímica y Reactividad de Materiales

Grupos de Investigación:

- Materiales Avanzados.

Responsable del Grupo: Dr. Pedro José Sánchez Soto

- Propiedades mecánicas, modelización y caracterización de cerámicos avanzados.

Responsable del Grupo: Dr. Diego Gómez García

- Reactividad de Sólidos.

Responsable del Grupo: Dra. Concepción Real Pérez

Profesores de Investigación

Pérez Maqueda, Luis AllanProfesor de Investigación CSIC ✉ maqueda@icmse.csic.es ☎ 954 48 96 32 ✆ 446132 ORCID 0000-0002-8267-3457 Reactividad de Sólidos |

Catedráticos

Gómez García, DiegoCatedrático Universidad de Sevilla ✉ dgomez@us.es ☎ 954 13 92 16 ✆ 446122 ORCID 0000-0002-5639-4796 Propiedades Mecánicas, Procesado y Modelización de Cerámicas Avanzadas |

Investigadores Científicos

Gotor Martínez, Francisco JoséInvestigador Científico CSIC ✉ francisco.gotor@icmse.csic.es ☎ 954 48 95 40 ✆ 446140 ORCID 0000-0002-8943-5291 Reactividad de Sólidos |

Real Pérez, ConcepciónInvestigadora Científica CSIC ✉ creal@icmse.csic.es ☎ 954 48 95 49 ✆ 446149 ORCID 0000-0002-3463-3629 Reactividad de Sólidos |

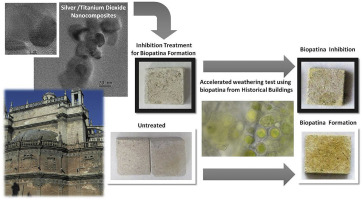

Sánchez Soto, Pedro JoséInvestigador Científico CSIC ✉ pedroji@icmse.csic.es ☎ 954 48 95 35 ✆ 446135 ORCID 0000-0002-2901-2975 Materiales Avanzados |

Científicos Titulares

Poyato Galán, RosalíaCientífica Titular CSIC ✉ rosalia.poyato@icmse.csic.es ☎ 954 48 96 28 ✆ 446156 ORCID 0000-0003-4376-6615 Reactividad de Sólidos |

Sánchez Jiménez, Pedro EnriqueCientífico Titular CSIC ✉ pedro.enrique@icmse.csic.es ☎ 954 13 92 15 ✆ 446119 ORCID 0000-0001-6982-1411 Reactividad de Sólidos |

Sayagués De Vega, María JesúsCientífica Titular CSIC ✉ mjsayagues@icmse.csic.es ☎ 954 48 96 29 ✆ 446157 ORCID 0000-0002-5555-310X Reactividad de Sólidos |

Profesores Titulares

Ayala Espinar, ReglaProfesora TitularUniversidad de Sevilla ✉ rae@icmse.csic.es ☎ 954 55 43 66 ORCID 0000-0003-4058-0727 Reactividad de Sólidos |

Perejón Pazo, AntonioProfesor TitularUniversidad de Sevilla ✉ antonio.perejon@icmse.csic.es ☎ 954 48 95 76 ORCID 0000-0002-5525-2227 Reactividad de Sólidos |

Doctores Contratados

Gil González, EvaDoctora ContratadaUniversidad de Sevilla ✉ eva.gil@icmse.csic.es ORCID 0000-0001-8464-8653 Reactividad de Sólidos |

Manchón Gordón, Alejandro FernandoDoctor ContratadoCSIC ✉ alejandro.manchon@icmse.csic.es ORCID 0000-0002-8320-5575 Reactividad de Sólidos |

Personal Investigador en Formación

Castro Chincho, AnaInvestigadora en FormaciónCSIC ✉ ana.castro@icmse.csic.es ✆ 446111 Reactividad de Sólidos |

Coto Ruiz, Francisco JavierJAE IntroCSIC Reactividad de Sólidos |

Delgado Álvarez, ClaraJAE IntroCSIC ☎ 954 13 92 07 ✆ 446111 Reactividad de Sólidos |

Linares Serrano, María TeresaJAE IntroCSIC Reactividad de Sólidos |

Robles Solano, EstherInvestigadora en FormaciónCSIC ✉ esther.robles@icmse.csic.es ☎ 954139207 ✆ 446111 Reactividad de Sólidos |

Santiago Andrades, LucíaJAE IntroCSIC Reactividad de Sólidos |

Diseño de cerámicas avanzadas con nanomateriales 2D para dispositivos electroquímicos de alta temperatura

Investigador Principal: Ana Morales Rodríguez / Rosalía Poyato Galán

Periodo: 01-09-2023 / 31-08-2027

Organismo Financiador: Ministerio de Ciencia e Innovación

Código: PID2022-140191NB-I00

Componentes: Ángela Gallardo López, Felipe Gutiérrez Mora, Rocío del Carmen Moriche Tirado

Grupo de Investigación: Reactividad de Sólidos

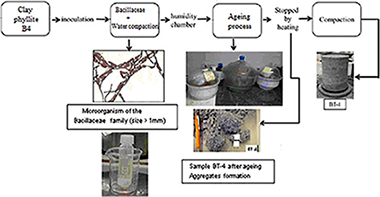

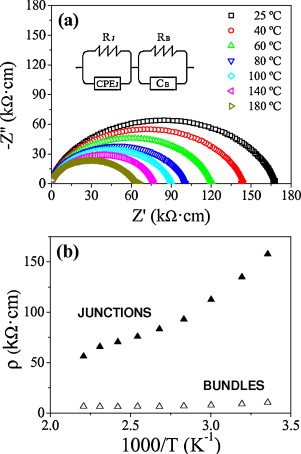

El avance en el conocimiento en el campo de los materiales compuestos de matriz cerámica con segunda fase de nanomateriales bidimensionales es fundamental de cara a su uso futuro en aplicaciones tecnológicas, como son los dispositivos electroquímicos de alta temperatura. Así, es muy necesaria una comprensión profunda de las bases de sus nuevas funcionalidades y su desempeño optimizado.

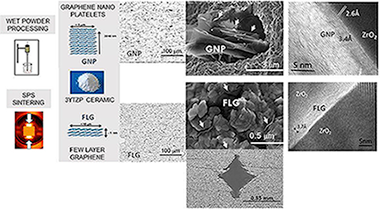

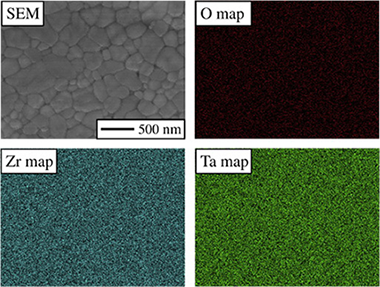

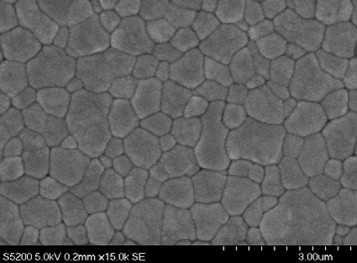

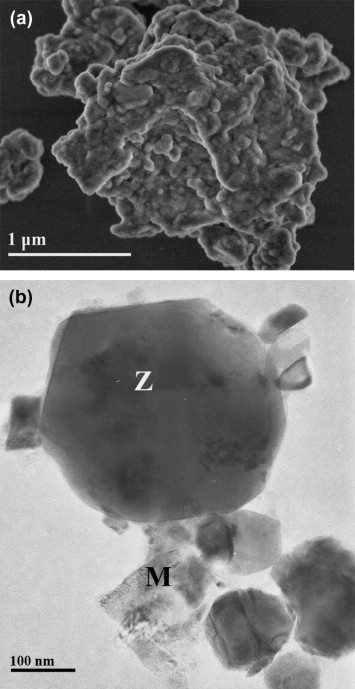

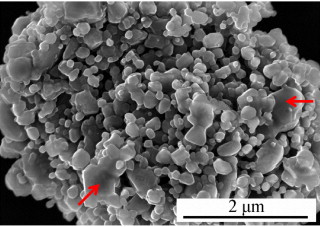

La presente propuesta presenta un estudio sistemático de composites con matriz de circona estabilizada con 8 %mol de itria y una segunda fase de nanomateriales laminares bidimensionales -grafeno o nanoláminas de nitruro de boro- pensados para su utilización en celdas de combustible de óxido sólido, con el objetivo de profundizar en la comprensión de los mecanismos que controlan su comportamiento térmico, mecánico y eléctrico.

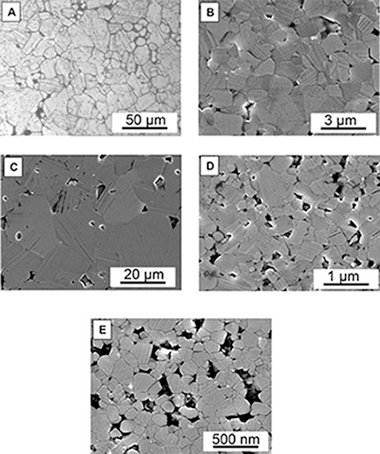

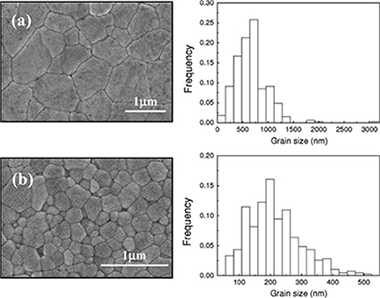

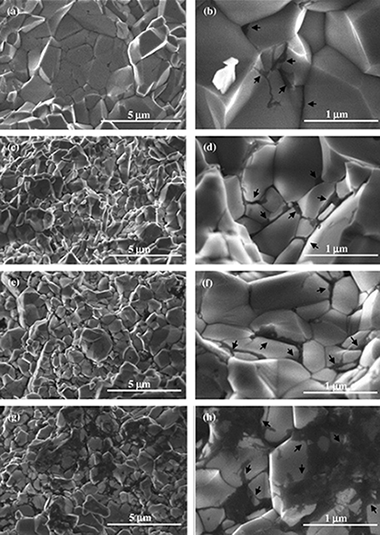

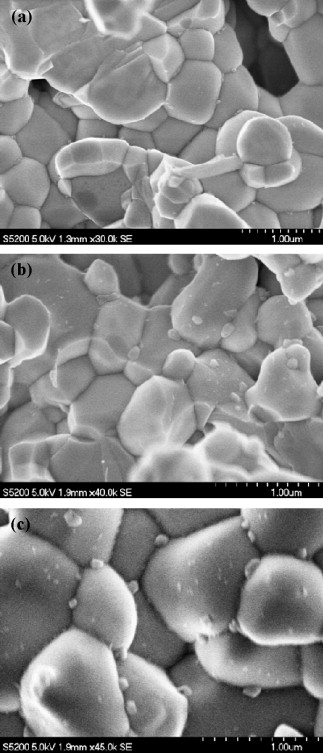

Se llevará a cabo un estudio de procesado con el objetivo de obtener composites con una microestructura optimizada, siempre persiguiendo una distribución homogénea del nanomaterial 2D en toda la matriz cerámica y una alta densidad. En un primer paso, se optimizará la rutina de procesado del polvo para mejorar la dispersión de la nanoestructura 2D en el polvo compuesto. En un segundo paso, se realizará un estudio de sinterización a diferentes temperaturas y presiones con el objetivo de obtener composites totalmente densos. Se analizará el efecto de la incorporación de la nanoestructura 2D sobre la microestructura del composite cerámico, para lo cual se evaluarán las fases cristalinas y la distribución, tamaño e integridad estructural de los nanomateriales 2D.

Se realizarán medidas de difusividad y conductividad térmica en función de la temperatura bajo diferentes atmósferas con el fin de analizar el efecto de la incorporación de la segunda fase, así como la posible orientación preferencial. Se realizarán ensayos de deformación a alta temperatura controlando las condiciones de tensión, temperatura y ambiente de trabajo, persiguiendo la identificación de los mecanismos microscópicos responsables del comportamiento de fluencia así como la comprensión de los mecanismos de fractura y plasticidad de los composites.

Se realizarán medidas de conductividad eléctrica en función de la temperatura para evaluar el efecto de la incorporación de las diferentes nanoestructuras 2D sobre el comportamiento eléctrico de los composites. Se identificará el tipo de conducción -iónica, mixta o electrónica- para los composites con diferentes contenidos de nanoláminas de grafeno.

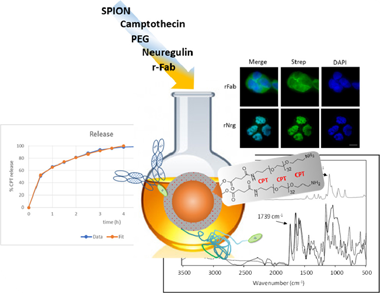

Diseño e impresión 3D de implantes bifásicos porosos personalizados para el tratamiento de defectos osteocondrales

Investigador Principal: Dr. Yadir Torres Hernández (US) y Dra. Ana Alcudia Cruz (US)

Periodo: 01-09-2023 / 31-08-2026

Organismo Financiador: Ministerio de Ciencia e Innovación

Código: PID2022-137911OB-I00

Componentes: Dr. Francisco José Gotor Martínez, Dr. Manuel de Miguel Rodríguez (US), Dra. Ana Isabel Raya Bermúdez (Universidad de Córdoba), Dr. Juan Morgaz Rodríguez (Universidad de Córdoba), Dra. María José Montoya García (US), Dr. Eugenio Velasco Ortega (US), Dra. Mercedes Giner García (US), Dra. Loreto Monsalve Guil (US), Dra. Belén Begines Ruiz (US), Dr. Francisco José García García (US)

Grupo de Investigación: Reactividad de Sólidos

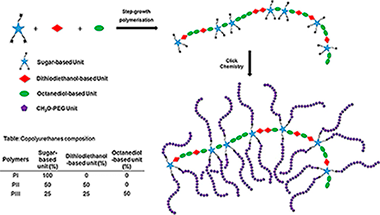

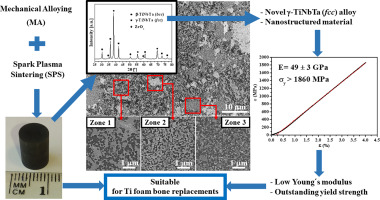

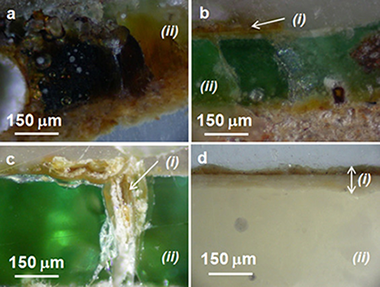

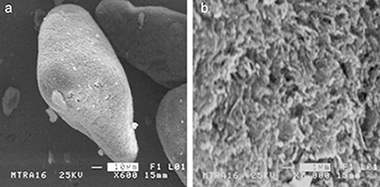

Actualmente, el número de lesiones musculoesqueléticas que requieren el reemplazo de tejido óseo y cartilaginoso está aumentando drásticamente. Estas condiciones, denominadas defectos osteocondrales (OCD), se derivan de diferentes enfermedades. La Comisión Lancet estimó que únicamente en 2020, más de 500 millones de personas se han visto afectadas por la osteoartritis, con un coste médico asociado entre el 1 % y el 2,5 % del producto interno bruto en países con alto nivel de vida.La mayoría de los tratamientos aplicados para el OCD solo se dirigen al tejido cartilaginoso, por lo que actualmente se está investigando el uso de implantes bifásicos para tratar simultáneamente ambos tejidos. Estos implantes están formados por una sección rígida que sustituye al tejido óseo subcondral y una sección blanda que imita el cartílago. En este proyecto se propone la novedosa fabricación de implantes bifásicos personalizados para el tratamiento del OCD en regiones articulares. El uso de la impresión 3D-Direct Ink Writing (DIW) para ambos tejidos permitirá una fabricación a medida completa del implante. Por un lado, se optimizará la impresión de una aleación de β-Ti para obtener una pieza 3D con equilibrio biomecánico y biofuncional mejorado, según la experiencia previa de nuestro grupo en la fabricación de implantes a base de Ti por diferentes metodologías. Esta tecnología permite el control de la porosidad del objeto cuya optimización, junto con el uso de la aleación de β-Ti, conducirá a un sustituto óseo con un módulo de Young cercano al tejido óseo huésped, reduciendo el problema de estrés sin comprometer el rendimiento mecánico.La impresora DIW utilizada incluirá dos depósitos, para imprimir simultáneamente dos tintas diferentes y un eje rotatorio para la impresión en la parte superior de la superficie curva del implante. Además, la inclusión de un composite a base de quitosano con vidrios bioactivos en la sección metálica potenciará la osteointegración y reducirá la proliferación bacteriana debido a la actividad antimicrobiana. Las piezas impresas más prometedoras se evaluarán in vitro, utilizando hOB, e in vivo en conejos blancos de Nueva Zelanda. Los resultados obtenidos con la aleación β-Ti impresa se compararán con los obtenidos a partir de sustratos de Ti comercialmente puro y diferentes aleaciones de Ti preparados previamente por el grupo de investigación con la técnica space-holder para seleccionar el sustituto óseo con mejores prestaciones. Por otro lado, se optimizará un biomaterial del tipo Red de Polímeros Interpenetrados (IPN), para generar un hidrogel con las propiedades para ser impreso y funcionar como el tejido del cartílago. Esta IPN contendrá 2 materiales poliméricos diferentes. El principal con carácter antibiofouling, (demostrad en equipo), y un crosslinker de carbohidratos hidrofílicos (mejora biocompatibilidad). El segundo polímero es ácido hialurónico reticulado con

una diamina hidrofílica derivada de azúcar (mejorara adhesión/proliferación condrocitos). Se evaluará la proporción componentes y porosidad obtenida con la estrategia de impresión para mantener el comportamiento antibiofouling pero ofreciendo el desempeño requerido en términos de viscoelasticidad y resistencia que mimetizan el cartílago. Además, se evaluará in vitro su comportamiento celular

y génico. Así, el implante bifásico final se fabricará utilizando los sustitutos de tejidos más prometedores y se probará in vivo en conejos blancos NZ.

Materiales para sistema híbrido de almacenamiento de energía térmica de alto rendimiento basado en sales fundidas y carbonatos

Investigador Principal: Luis Allan Pérez Maqueda / Antonio Perejón Pazo

Periodo: 01-09-2023 / 31-08-2026

Organismo Financiador: Ministerio de Ciencia e Innovación

Código: PID2022-140815OB-C22

Componentes: Pedro Enrique Sánchez Jiménez, José Manuel Valverde Millán (US)

Grupo de Investigación: Reactividad de Sólidos

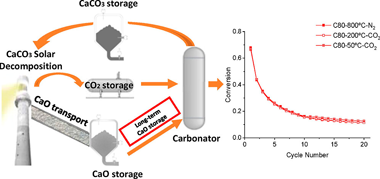

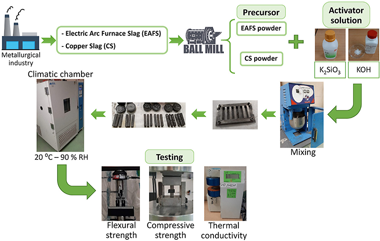

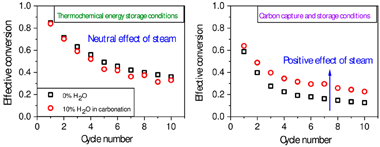

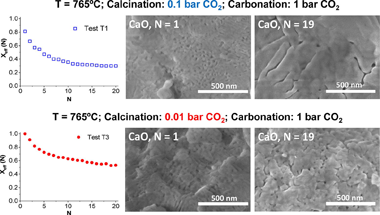

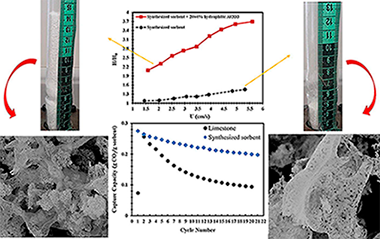

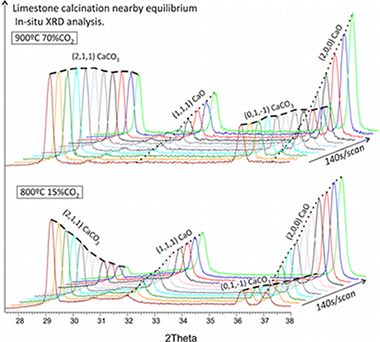

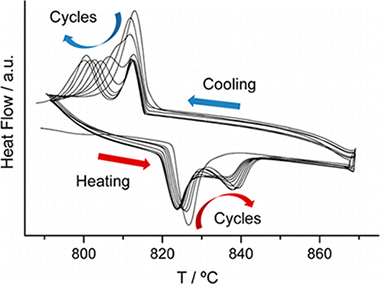

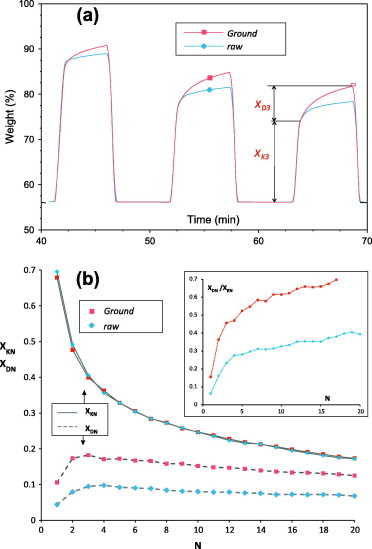

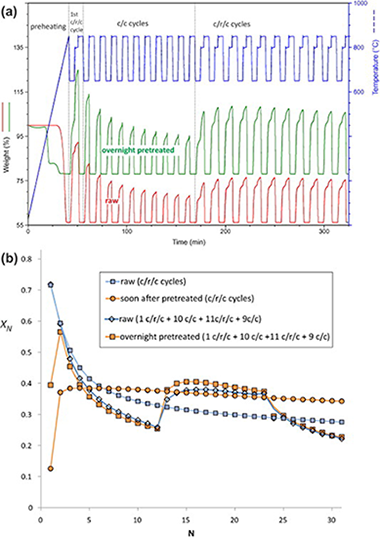

El objetivo principal del proyecto HIPERTES es el desarrollo de un nuevo concepto de almacenamiento termoquímico de energía de alta temperatura basado en un sistema híbrido de carbonatos y sales fundidas en un único reactor. El subproyecto 2 se centra principalmente en los aspectos relacionados con el desarrollo de materiales adecuados a estas nuevas condiciones de operación, así como a la optimización de las mismas y el estudio del comportamiento de los materiales durante los ciclos termoquímicos.

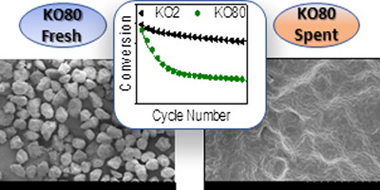

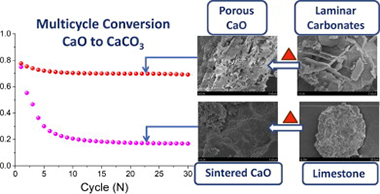

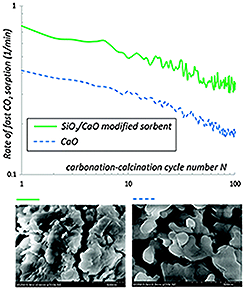

Si bien existen soluciones basadas en el uso de aditivos sólidos para intentar mejorar la ciclabilidad y el rendimiento de procesos termoquímicos basados en reacciones de carbonatación/calcinación, estas soluciones tienen un límite, pues siempre se observa un decaimiento de la actividad con el número de ciclos que se hace más evidente a manera que aumenta el número de éstos. En este proyecto se propone una solución novedosa basada en sistemas híbridos de carbonatos con sales fundidas. Las sales aportaran un incremento de la reactividad tanto de calcinación como de carbonatación, mejorando sobre todo las cinéticas de los procesos difusivos.

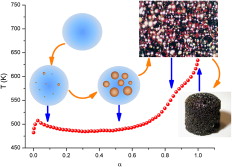

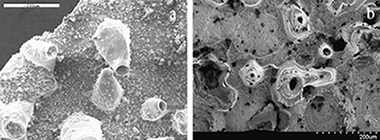

Así, se espera que las sales aporten (i) cinéticas rápidas de calcinación y carbonatación para que los procesos de carga y descarga sean lo más rápidos posibles y (ii) alta estabilidad multicíclica evitando los procesos de desactivación por sinterizado y bloqueo de poros. Se proponen dos tipos de sistemas, uno basado en pellets porosos que se impregnarían con las sales y otro basado en baños de sales fundidas donde se dispersarían las partículas de carbonato. Para la primera solución se usarán técnicas de peletizado que permitan obtener pellets porosos a partir de suspensiones acuosas de partículas de carbonatos tanto minerales como sintéticas. Los pellets obtenidos se impregnarán con sales de alta temperatura. En la segunda solución, se seleccionarán mezclas de sales de alta estabilidad térmica en las que se dispersarán partículas o pellets de carbonatos. Para la preparación de los pellets porosos se usarán técnicas de “freeze granulation” que permiten obtener pellets porosos y estables a partir de suspensiones de partículas. Todos los materiales preparados se caracterizarán en cuanto a sus propiedades termofísicas y a su comportamiento multicíclico. Se establecerán las condiciones óptimas de funcionamiento, así como los rangos máximos de trabajo. Estos resultados se usarán como parámetros para el subproyecto 1.

El subproyecto 2 cuenta con la participación de un equipo multidisciplinar con experiencia en química, reactividad de sólidos, cinética heterogénea, física y ciencia de materiales para completar los objetivos propuestos. Tienen experiencia y solvencia avalada en la ejecución de proyectos nacionales e internacionales, además de proyectos industriales, en el campo del diseño y caracterización de materiales para el almacenamiento de energía térmica.

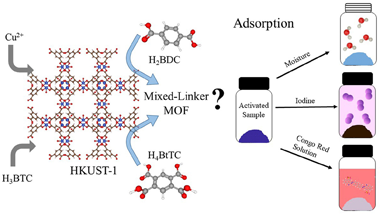

Técnicas innovadoras basadas en campos eléctricos para la preparación de baterías de estado sólido

Investigador Principal: Eva Gil González

Periodo: 01-09-2023 / 31-08-2026

Organismo Financiador: Ministerio de Ciencia e Innovación

Código: PID2022-141199OA-I00 (Proyectos Investigación Orientada)

Componentes: Xin Li, Sandra Molina Molina, Ahmed Taibi

Grupo de Investigación: Reactividad de Sólidos

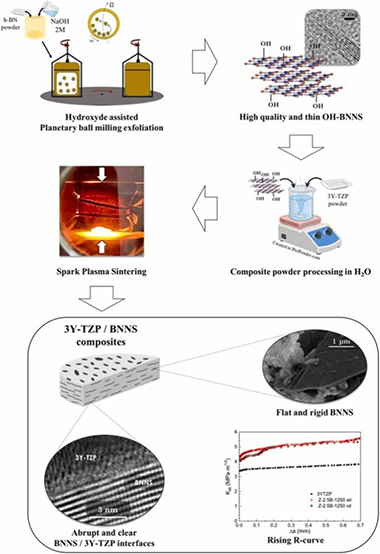

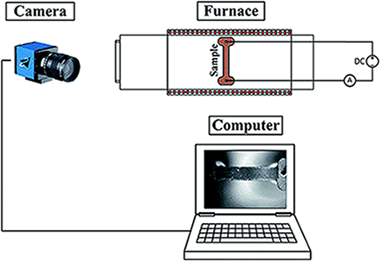

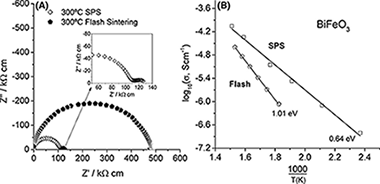

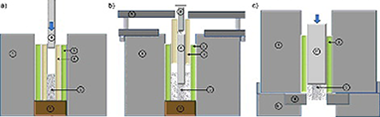

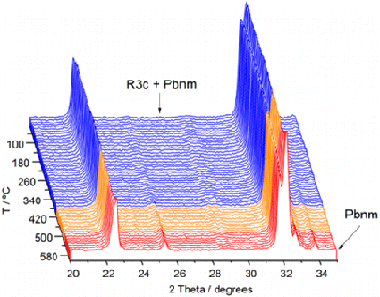

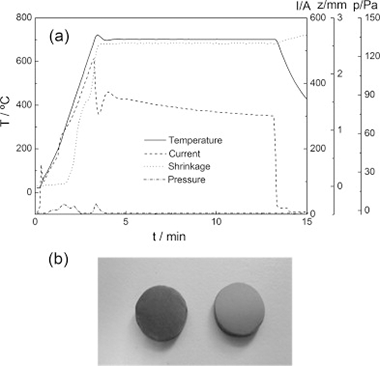

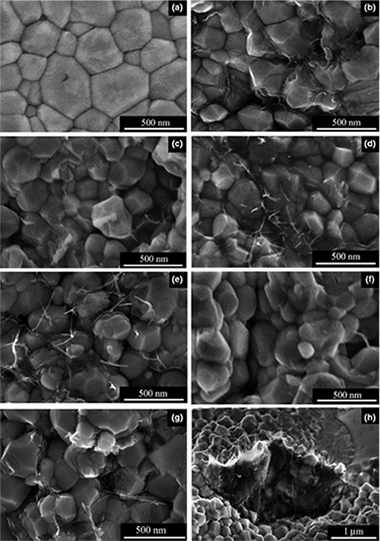

El desarrollo de las tecnologías de almacenamiento energético es fundamental para la transición hacia una economía climáticamente neutra. Las Baterías de Estado Sólido (BES) se presentan como candidatas prometedoras para solventar los graves problemas que presentan las baterías de ion litio que dominan el mercado tecnológico actual. Las BES reemplazan el electrolito líquido, orgánico e inflamable, de estos dispositivos por un sólido no inflamable, lo que aumenta la seguridad de estos dispositivos, entre muchas otras ventajas. Así, en las últimas décadas los electrolitos sólidos han experimentado un gran avance, donde un grupo muy importante lo conforman los electrolitos cerámicos tipo óxidos y fosfatos, por sus altas conductividades iónica, amplia venta de potencial electroquímico y compatibilidad con litio metálico. Sin embargo, las altas temperaturas (por tiempo prolongado) que se requieren para su síntesis y procesado conllevan un gran consumo energético, lo que limita su competitividad económica y, además, favorece la volatilización de los iones litios, deteriorando de manera inevitable sus propiedades. También, el proceso de co-sinterizado con los demás elementos activos de la celda (ánodo y cátodo) es bastante complicado por la aparición de fases secundarias y grandes resistencias interfaciales que merman la vida útil de las BES. Precisamente esta problemática es uno de los grandes retos a abordar para impulsar el desarrollo de estos dispositivos. INNOBEC propone un enfoque innovador para abordar este desafío mediante el empleo de las técnicas de sinterizado Flash (FS) a las BES. El FS consiste en aplicar simultáneamente un campo eléctrico y calor a una muestra cerámica, de tal forma que la densificación del material se consigue de manera casi instantánea y a temperaturas muchos menores que las empleadas en métodos convencionales. Con ello, no solo se reduce el gasto energético, sino que también se facilita el procesado de materiales cuya estabilidad térmica es limitada, como son los electrolitos sólidos. Además, las técnicas de FS son consideradas de “no equilibrio”, lo posibilita la obtención de materiales con propiedades mejoras, tales como superplasticidad en cerámicas o conductividades iónicas superiores, por la generación de una gran cantidad de defectos. Asimismo, las técnicas de FS son altamente versátil ya que también se ha demostrado que mediante la sinterización reactiva Flash (RFS) se puede inducir la reacción química y densificación de materiales cerámicos en un solo paso, lo que mejora aún más la eficiencia del proceso y aumenta las posibilidades brindadas por la técnica.

INNOBEC pretende usar las ventajas competitivas ofrecidas por las técnicas de FS y RFS de menores tiempos y temperaturas de procesado para obtener materiales con propiedades optimizadas para BES, específicamente electrolitos sólidos cerámicos, tipo óxidos y fosfatos, y composites cerámicos con conducción mixta iónica-electrónica para cátodos o ánodos. El objetivo final de INNOBEC es el co-sinterizado en un solo paso de estructuras multicapas tipo BES y la evaluación de su rendimiento electroquímico. INNOBEC es un proyecto novedoso, que fusiona la experiencia previa de la IP tanto en el ámbito de las BES como FS, donde se apuesta por una nueva metodología altamente eficiente que facilite la preparación y procesado de los electrolitos sólidos y, además, palíe los graves problemas derivados del co-sinterizado que frenan el desarrollo de las BES.

Técnicas Flash para la obtención de óxidos de alta entropía con propiedades magnéticas (FOMAG)

Investigador Principal: Alejandro Fernando Manchón Gordón

Periodo: 01-02-2023 / 31-08-2025

Organismo Financiador: Junta de Andalucía

Código: ProyExcel_00360

Componentes:

Grupo de Investigación: Reactividad de Sólidos

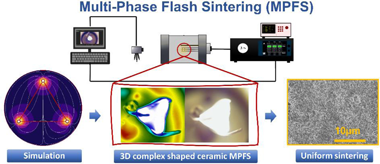

El proyecto FOMAG se centra en la aplicación de novedosas técnicas de sinterizado rápido, como el Sinterizado Flash (FS), el Sinterizado Flash Reactivo (SFR) y el Sinterizado Flash Multifásico (MPFS), para la síntesis de óxidos de alta entropía (HEOs) con propiedades magnéticas de interés tecnológico. A pesar de que la técnica FS se propuso por primera vez en 2010, la SFR en 2018 y la MPFS en 2022, el interés por este proceso ha experimentado un notable crecimiento en diversas áreas científicas debido a su gran potencial científico y tecnológico.

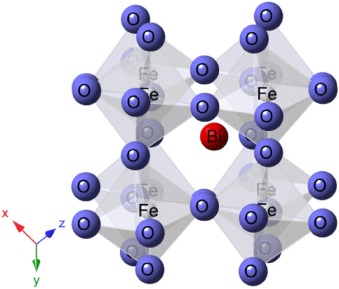

Estas técnicas permiten la fabricación de materiales cerámicos a temperaturas y tiempos considerablemente inferiores a los requeridos por los métodos de sinterización convencionales, mediante la aplicación de una pequeña corriente eléctrica a través de la muestra. Además, las condiciones experimentales particulares de las técnicas Flash hacen posible la obtención de materiales cerámicos densos y nanoestructurados, lo cual resulta desafiante mediante métodos convencionales. De manera significativa, el sinterizado Flash no solo reduce de forma drástica el consumo energético necesario para el procesamiento de materiales cerámicos, sino que también amplía sus aplicaciones a nuevos materiales con fines tecnológicos. En este contexto, los HEOs son una clase emergente de materiales cerámicos que contienen cinco o más cationes en composiciones equimolares. La singularidad de estos sistemas, propuestos por primera vez en 2015, radica en su extrema complejidad química, combinada con su simplicidad cristalográfica, ya que los átomos se ordenan en una única estructura cristalina relativamente sencilla, superando las separaciones de fases típicas de sistemas altamente dopados. En términos de la estructura local, estos materiales constan de un número excepcionalmente alto de combinaciones diferentes de enlaces metal-oxígeno-metal, lo que afecta de manera inherente las interacciones magnéticas en función de factores como la geometría de coordinación, la valencia y el tipo de cationes metálicos circundantes. Esto da lugar a una diversidad de respuestas magnéticas muy interesantes.

FOMAG propone la aplicación de las técnicas FS, RFS y MPFS en la producción de HEOs con propiedades magnéticas, aprovechando las ventajas intrínsecas de estas técnicas, especialmente en la obtención de una alta densidad en sistemas donde esto resulta especialmente desafiante.

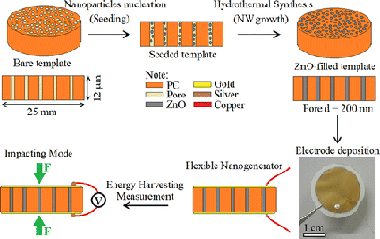

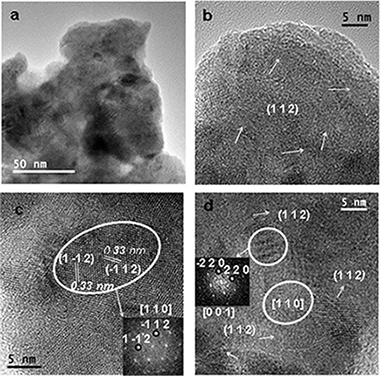

Desarrollo de Nanogeneradores Piezoeléctricos Flexibles y de alta Eficiencia basados en Nanocompuestos Perovskita/PVDF (NANOGEN)

Investigador Principal: Rocio Moriche Tirado

Periodo: 01-12-2022 / 30-11-2024

Organismo Financiador: Ministerio de Ciencia e Innovación

Código: TED2021-131458A-I00

Componentes: Francisco José Gotor Martínez (ICMS), María Jesús Sayagués de Vega (ICMS), Rosalía Poyato Galán (ICMS), Ana Morales Rodríguez (US), Felipe Gutiérrez Mora (US), Ángela Gallardo López (US)

Grupo de Investigación: Reactividad de Sólidos

Materiales termoquímicos para almacenamiento de energía mejorados mediante control microestructural

Investigador Principal: Luis Allan Pérez Maqueda / Pedro Enrique Sánchez Jiménez

Periodo: 01-09-2022 / 30-11-2024

Organismo Financiador: Ministerio de Ciencia e Innovación

Código: TED2021-131839B-C22

Componentes: Joaquín Ramírez Rico, José Manuel Valverde Millán, Antonio Perejón Pazo

Grupo de Investigación: Materiales de Diseño para la Energía y Medioambiente, Reactividad de Sólidos

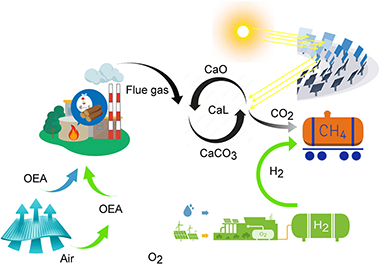

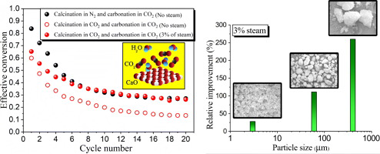

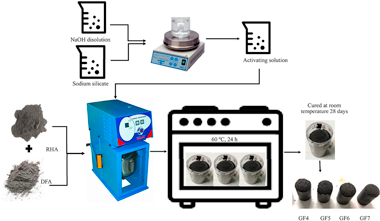

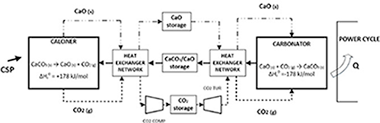

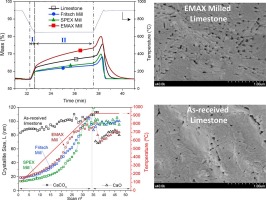

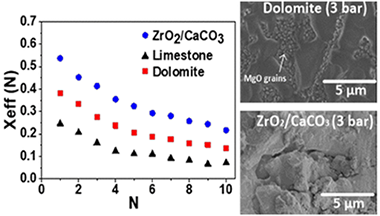

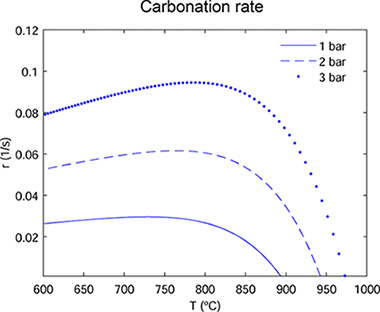

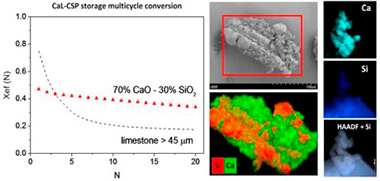

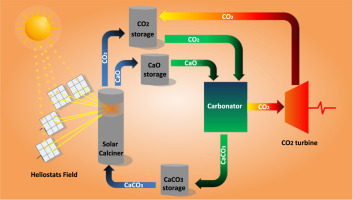

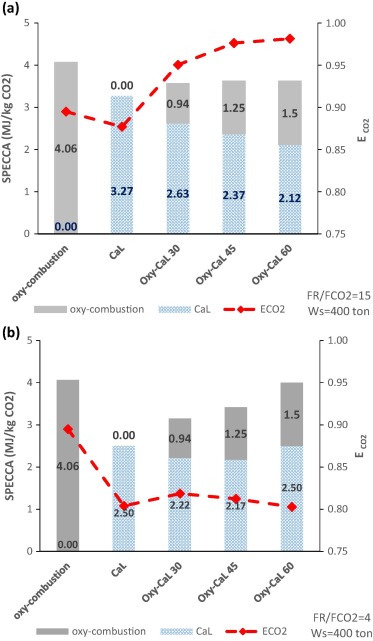

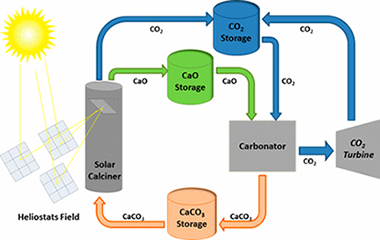

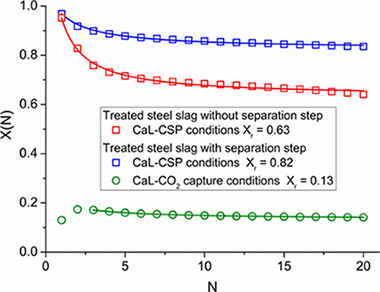

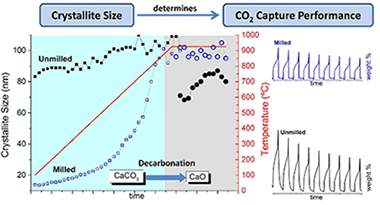

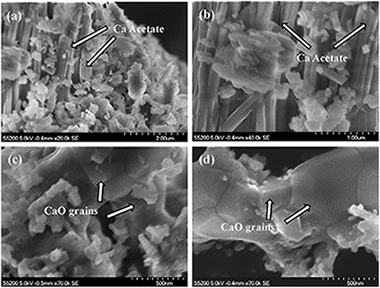

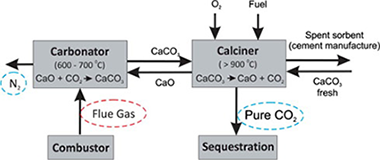

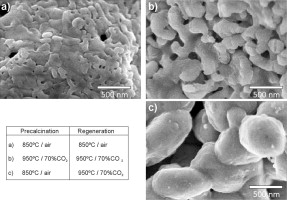

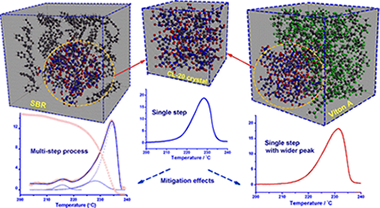

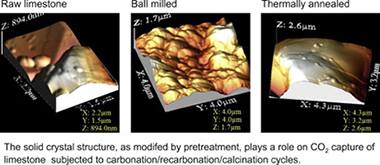

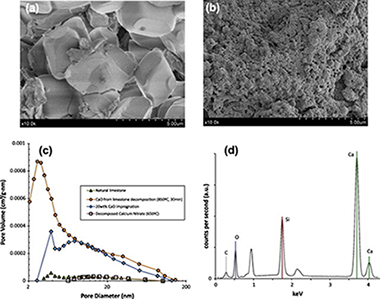

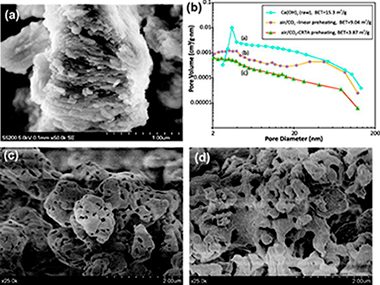

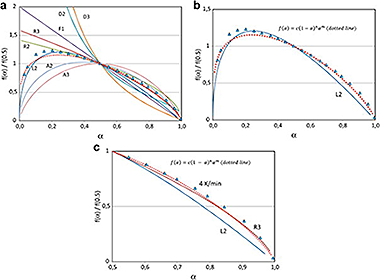

El objetivo principal del proyecto MOTHERESE es el desarrollo de un nuevo concepto de almacenamiento termoquímico de energía basado en el proceso de “Calcium-Looping”. La novedad del concepto radica en disminuir la escala del componente de almacenamiento y dotarlo de un carácter modular, fácilmente integrable en plantas de generación de energía de diversa naturaleza, almacenable y móvil. El subproyecto 2 se se centra en los aspectos relacionados con el desarrollo de materiales adecuados a estas nuevas condiciones de operación, así como a la optimización de las mismas a esta nueva escala.

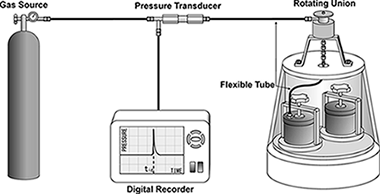

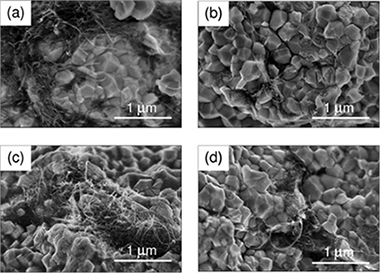

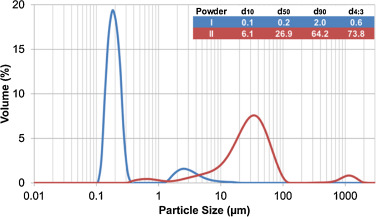

Se pretende abordar el desarrollo de estos materiales haciendo hincapié en técnicas de preparación que favorezcan morfologías y microestructuras que optimicen (i) la cinética de las reacciones sólido-gas, con el objeto de reducir los tiempos de residencia, (ii) estabilidad multicíclica, minimizando la desactivación por sinterizado y bloqueo de poros, y (iii) superficie activa, maximizando la cantidad de reactivo disponible para conversión en cada ciclo. Esto se conseguirá utilizando las técnicas de freeze casting y freeze granulation, especialmente adecuadas para la fabricación de estructuras cerámicas con porosidad abierta y morfología dirigida. También se plantea el uso de aditivos que mejoren el rendimiento del material. Finalmente, se contempla la integración del material activo y aditivos de alta conductividad térmica en estructuras tridimensionales estables, que no solo mejoren la ciclabilidad y eficiencia del material activo sino también asegure transferencias de calor rápidas y eficientes, necesarias para el sistema modular. Finalmente, se van a explorar nuevas condiciones de operación compatibles con la nueva escala, desde presiones reducidas hasta altas presiones de hasta 5 bares, manteniendo siempre un ciclo cerrado que evite la necesidad de separación de gases.

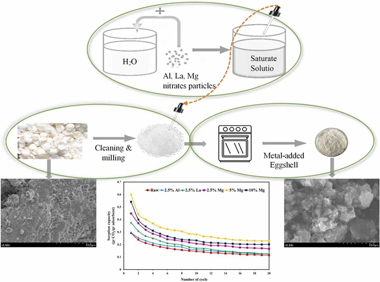

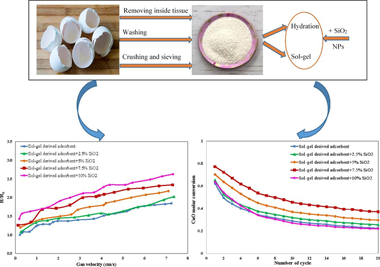

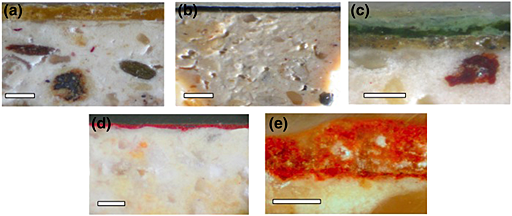

MOTHERESE apuesta por la economía circular, por lo que apunta al uso, como fuente de los aditivos e incluso del propio material activo, CaO, de subproductos y residuos procedentes de otras industrias, favoreciendo el aprovechamiento de residuos. Entre los planteados, escoria de acería, carbonatos biogénicos (moluscos), materiales celulósicos y cascarilla de arroz (fuente de SiO2).

Para abordar estos objetivos, el subproyecto cuenta con un equipo multidisciplinar de químicos, ingenieros, físicos y especialistas en materiales con experiencia en la gestión y participación en proyectos de investigación nacionales e internacionales, incluyendo proyectos relevantes centrados en almaceamiento termoquímico de energía. Además, el equipo tiene una red internacional de colaboradores tanto académicos como industriales que permitiría en la explotación de los resultados obtenidos y la propuesta de nuevos proyectos internacionales en esta misma línea.

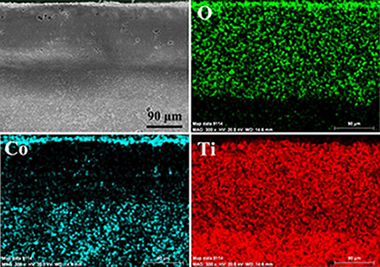

Diseño y selección de materiales novedosos para fabricar pilas de combustible de óxido sólido reversibles de alto rendimiento (Layered rSSOCs)

Investigador Principal: Francisco José García García (US) / Juan Gabriel Lozano Suárez (US)

Periodo: 01-12-2022 / 30-11-2024

Organismo Financiador: Ministerio de Ciencia e Innovación

Código: TED2021-132057B-I00

Componentes: Francisco José Gotor Martínez (ICMS), María Jesús Sayagués de Vega (ICMS), Yadir Torres Hernández (US), Isabel Montealegre Meléndez (US), Cristina María Arévalo Mora (US), Ana María Beltrán Custodio (US), Eva María Pérez Soriano (US), Paloma Trueba Muñoz (US)

Grupo de Investigación: Reactividad de Sólidos

Fabricación de materiales porosos de base hierro con características refractarias para sistemas de purificación, uso y almacenaje de hidrógeno (FePoMat2)

Investigador Principal: Ranier Enrique Sepúlveda Ferrer (US) / Ernesto Chicardi Augusto (US)

Periodo: 01-09-2022 / 31-08-2026

Organismo Financiador: Ministerio de Ciencia e Innovación "Generación de Conocimiento"

Código: PID2021-123010OB-I00

Componentes: Dr. Antonio Gabriel Paúl Escolano (US), Dr. Jesús Hernández Saz (US), Dr. Krishnakumar Balu (US) ICMS: Dr. Francisco José Gotor Martínez

Grupo de Investigación: Reactividad de Sólidos

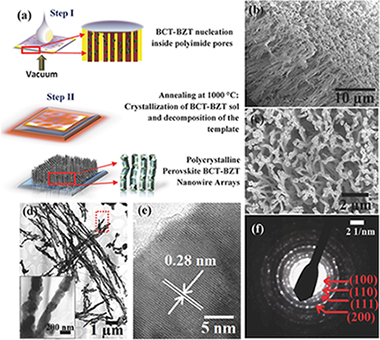

Nuevos scaffolds piezoeléctricos de compuestos nanoestructurados para la regeneración ósea mediante fabricación aditiva (PIZAM)

Investigador Principal: Mario Monzón / Rubén Paz

Periodo: 01-09-2021 / 31-08-2024

Organismo Financiador: Ministerio de Ciencia e Innovación

Código: PID2020-117648RB-I00. Plan Estatal 2017-2020 Retos Proyectos I+D+i

Componentes: Óscar Martel, Alberto Cuadrado, María Jesús Sayagués, Rocío Moriche, Ricardo Donate, M. Elena Alemán, Pablo Bordón, Paula Fiorucci, Francisco J. Rodríguez, Joaquín M. Antunes, Chaozong Liu

Grupo de Investigación: Reactividad de Sólidos

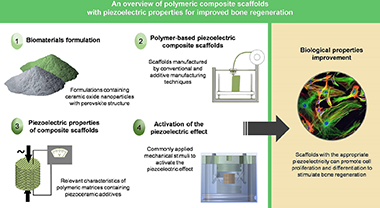

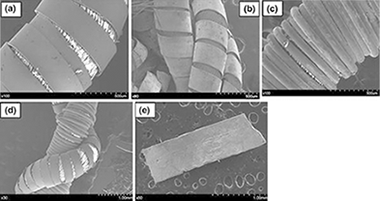

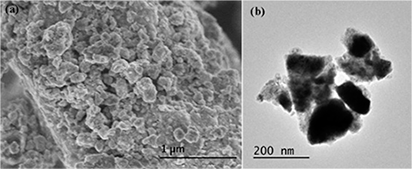

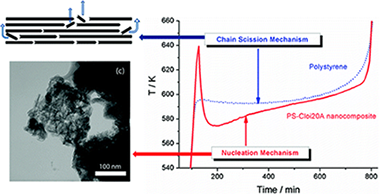

A pesar del drástico cambio que la ingeniería de tejidos o las terapias con células madre han introducido en las estrategias terapéuticas actuales, todavía existe una falta de funcionalidades en los biomateriales disponibles para el desarrollo de scaffolds para diversas patologías (grandes defectos osteocondrales, osteoporosis, etc.) que afectan a una gran parte de la población. PIZAM aborda este reto aportando scaffolds piezoeléctricos innovadores mediante Fabricación Aditiva (FA) basada en extrusión de material para mejorar la regeneración ósea. Los scaffolds con piezoelectricidad apropiada son capaces de influir positivamente en el proceso de proliferación y diferenciación de células mesenquimales para la regeneración de hueso, ya que existe evidencia científica de la relevancia que tienen las cargas eléctricas superficiales en el proceso de mecanotransducción por el cual las cargas mecánicas influyen sobre la respuesta biomolecular en el tejido óseo (material piezoeléctrico).

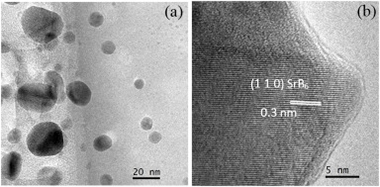

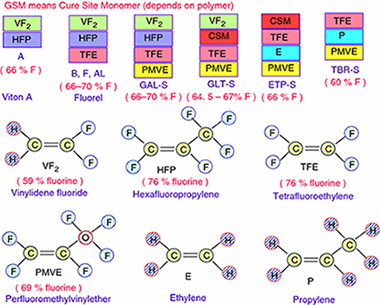

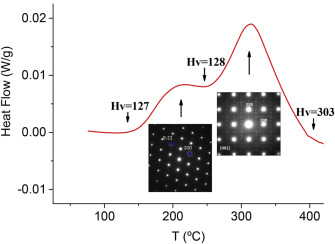

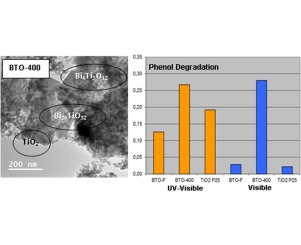

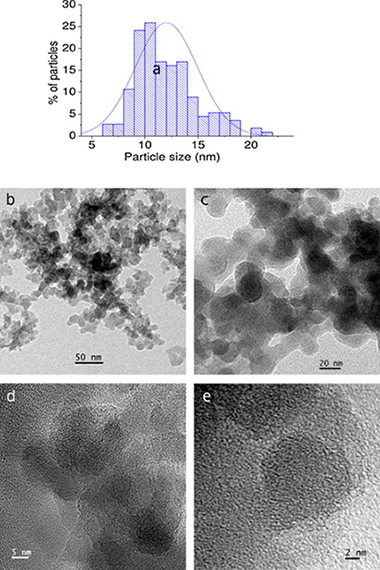

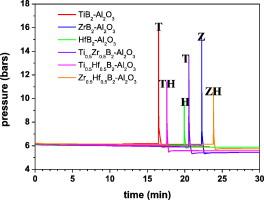

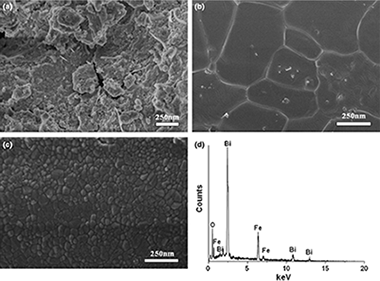

Para ello, PIZAM desarrollará materiales innovadores basados en compuestos nanoestructurados conteniendo Ba(Ti,Zr)O3-(Ba,Ca)TiO3 (nanopartículas de óxido cerámico sin plomo con estructura de perovskita). Estos materiales piezoeléctricos se suelen sintetizar mediante una reacción de estado sólido a alta temperatura o métodos basados en disoluciones, que son complejos, costosos y poco respetuosos con el medio ambiente. En PIZAM, la cerámica piezoeléctrica nanoestructurada se obtendrá por mecanosíntesis, una alternativa ecológica con menores costos de producción, desechos y consumo de energía. Las nanopartículas producidas se dispersarán en dos matrices poliméricas: PVDF (biocompatible y con elevada piezoelectricidad) y PLA (biocompatible, biorreabsorbible, baja toxicidad, alto rendimiento mecánico y con cristalinidad/piezoelectricidad ajustable).

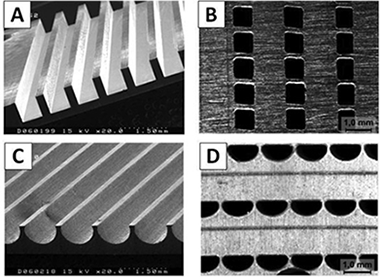

Los materiales desarrollados serán procesados para obtener pellets/polvos que se utilizarán como materia prima para la producción de filamentos por extrusión. Estos filamentos se someterán a pruebas de procesabilidad en un equipo de FA de extrusión de material para optimizar los parámetros del proceso mediante algoritmos genéticos e interpolación Kriging. Durante las etapas de fabricación, se llevarán a cabo diferentes caracterizaciones para analizar el efecto de estos procesos en las propiedades fisicoquímicas/piezoeléctricas.

A continuación, se llevará a cabo un proceso de optimización del diseño de los scaffolds para la regeneración del tejido óseo mediante análisis por elementos finitos y algoritmos genéticos. Las estructuras óptimas se producirán por FA y se caracterizarán (propiedades mecánicas y piezoeléctricas). En el caso de scaffolds basados en PLA, se evaluará la evolución de estas propiedades a lo largo del tiempo de degradación. Aprovechando el efecto piezoeléctrico, se realizará una evaluación de las capacidades de los scaffolds para la monitorización en tiempo real.

Por último, el rendimiento biológico de los scaffolds se confirmará mediante un modelo in vitro con células mesenquimales y diferentes estímulos mecánicos para activar el efecto piezoeléctrico: una evaluación inicial sin estimulación (control); estimulación por ultrasonidos; y estimulación en un biorreactor de perfusión. Se analizará la proliferación, viabilidad y diferenciación de las células madre para comprender la relación en el proceso de mecanotransducción y su efecto en la respuesta biológica de los scaffolds.

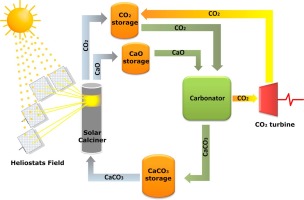

Demostración en entorno relevante del uso de reacciones de calcinación-solar/carbonatación para almacenamiento de energía térmica

Investigador Principal: Luis A. Pérez Maqueda / Pedro Enrique Sánchez Jiménez

Periodo: 01-12-2021 / 30-11-2023

Organismo Financiador: Ministerio de Ciencia e Innovación

Código: PDC2021-121552-C21 - Proyectos I+D+i "Prueba de Concepto"

Componentes:

Grupo de Investigación: Reactividad de Sólidos

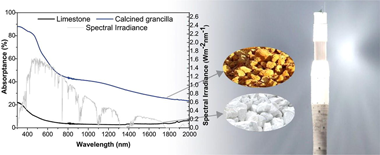

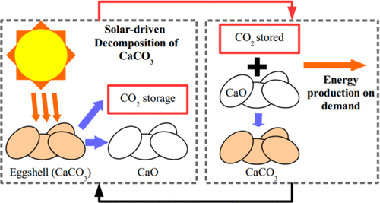

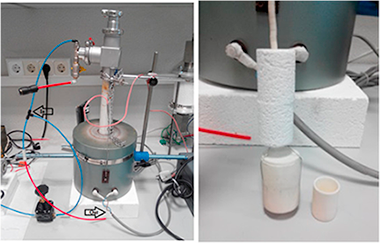

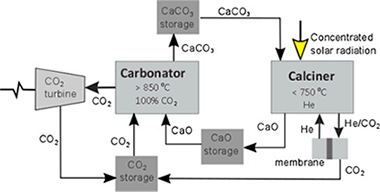

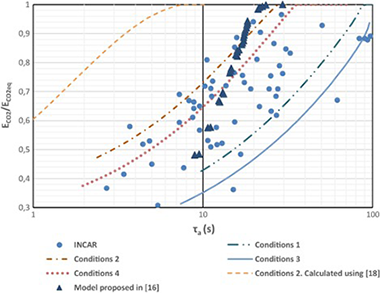

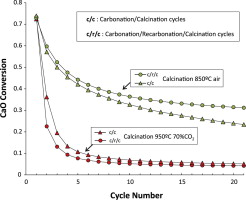

España es uno de los países europeos con mayor irradiación solar media y lider mundial en implantación de Energía Solar Concentrada (CSP). Una ventaja de la tecnología CSP es su capacidad de almacenar energía térmica y usarla cuando no hay irradiación. La plantas CSP de última generación incluyen sistemas de almacenamiento en sales fundidas (calor sensible) que pesentan limitaciones: temperatura máxima limitada por degradación térmica, almacenaje a alta temperatura para evitar solidificación, corrosión y coste. En nuestro proyecto CTQ2017 se investigó el almacenamiento termoquímico mediante reacciones de calcinación/carbonatación, proceso calcium-lopping (CaL), usando caliza natural, que es abundante, barata, no corrosiva y permite operar a alta temperatura aumentando la eficiencia de conversión termoeléctrica. Su densidad energética (~1 MWhr/m3) es superior al de las sales (0.25-0.40 MWhr/m3). Un problema del CaL para almacenamiento termoquímico es la desactivación del CaO con el número de ciclos. En nuestro proyecto CTQ2017 se propusieron diversas estrategias de mejora con las que se consiguieron rendimientos muy altos incluso después de muchos ciclos: (i) cambio de condiciones de calcinación-carbonatación (reducción de la temperatura de calcinación e incrementar la de carbonatación para mejorar el rendimiento tanto del proceso como de la planta) y (ii) propuesta de otros carbonatos diferentes de la caliza, uso de aditivos, uso de residuos (escorias) y materiales sintéticos de bajo coste. Estos resultados de laboratorio son de extraordinario interés para su aplicación a plantas de CSP, pero para su transferencia se requiere de validación en entorno relevante. En este proyecto se propone escalar los resultados de laboratorio mediante ensayos en planta piloto, el desarrollo y ensayo de un nuevo calcinador solar, así como la evaluación de la viabilidad técnico-económica de la tecnología a escala industrial. En este proyecto se desarrollará una prueba de concepto de un novedoso reactor/intercambiador de calor de tipo ciclón basado en energía solar. La radiación solar concentrada alcanzará el calcinador solar tipo ciclón mediante un sistema beam-down (concentrador solar secundario) desde el campo solar, formado por 14 heliostatos con una superficie total de 30 m2 de la planta piloto construida en el marco del proyecto H2020 SOCRATCES, en el que han participado la mayor parte de los miembros del equipo de investigación del proyecto coordinado. El estudio y desarrollo de esta prueba de concepto permitirá establecer la viabilidad del diseño y demostrar su interés a empresas del sector energético y del cemento de cara a una futura integración de energía solar, en busca de una reducción de costes y emisiones de CO2. Se parte de estudios a nivel de concepto desarrollados en el proyecto CTQ2017 con nivel de madurez tecnológica TRL 4, y se estima que se avanzará hasta niveles TRL 5-6. Se realizará un análisis de la viabilidad económica de la implantación de los nuevos conceptos propuestos en el marco del proyecto CTQ2017 y se elaborará un plan de transferencia. Este plan recogerá las acciones a llevar a cabo para favorecer una transferencia efectiva al sector industrial. Además, dado el potencial de patentabilidad de la tecnología objeto del proyecto, una vez probada en escala relevante (prueba de concepto), se desarrollará un plan de explotación y protección de derechos intelectuales.

Cerámicas en un Flash: La La nueva ruta para un procesado energética y medioambientalmente eficiente

Investigador Principal: Luis A. Pérez Maqueda

Periodo: 01-01-2021 / 31-12-2022

Organismo Financiador: Junta de Andalucia

Código: P18-FR-1087 "Frontera"

Componentes: M. Jesús Diánez Millán, Pedro Enrique Sánchez Jiménez

Grupo de Investigación: Reactividad de Sólidos

El proyecto CeramFLASH propone la utilización de las novedosas técnicas de Sinterizado Flash (FS) y Sinterizado Flash Reactivo (SFR) para la síntesis y preparación de cerámicas con interés tecnológico tales como electrolitos sólidos, piezoeléctricos o cerámicas duras electromecanizables. Estas técnicas permiten preparar materiales cerámicos en segundos a temperaturas significativamente más bajas que las requeridas por las técnicas de sinterizado convencional simplemente haciendo circular por la pieza una muy pequeña intensidad de corriente eléctrica (de unos pocos miliamperios). Esta ventaja permite reducir de forma significativa el elevado consumo energético necesario en el procesado de materiales cerámicos.

Adicionalmente, se posibilita la preparación en forma densa y nanoestructurada de cerámicas muy difíciles de preparar mediante métodos convencionales, tales como compuestos de baja estabilidad térmica o compuestos que requieren temperaturas de sinterizado muy elevadas.

Finalmente, CeramFLASH pretende utilizar campos alternos con frecuencia de oscilación variable y métodos de control inteligente basados en la respuesta de la muestra al campo para conseguir un mejor control de las características microestructurales en las cerámicas resultantes. A pesar de que la técnica de FS se propuso por vez primera hace solo 8 años, y la SFR fue introducida en 2018 por nuestro grupo, el interés por este proceso está creciendo de forma importante por su gran potencial científico y tecnológico. CeramFLASH cuenta con la implicación de personal con experiencia en la técnica y la colaboración activa del investigador pionero en su propuesta, por lo que su financiación permitirá establecer una línea de investigación a largo plazo que permita consolidar en Andalucía un grupo de referencia a nivel internacional en este ámbito.

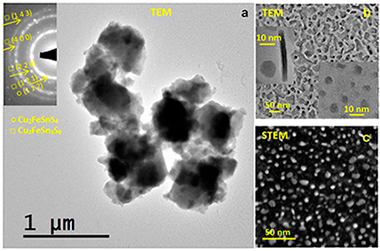

Diseño y selección de materiales novedosos para fabricar pilas de combustible de óxido sólido de alto rendimiento

Investigador Principal: Francisco José García García (US)

Periodo: 01-02-2020 / 31-01-2022

Organismo Financiador: Junta de Andalucía

Código: US-15382 "Emergente"

Componentes: Francisco J. Gotor Martínez

Grupo de Investigación: Reactividad de Sólidos

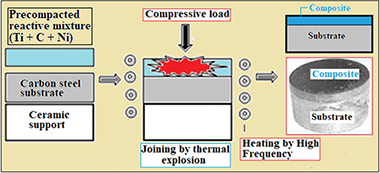

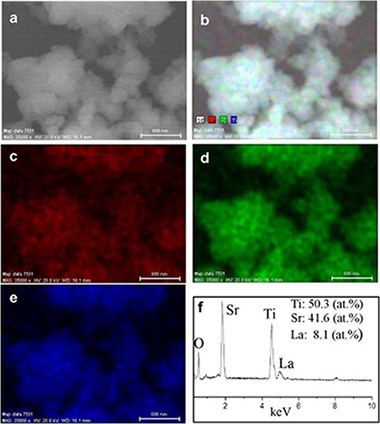

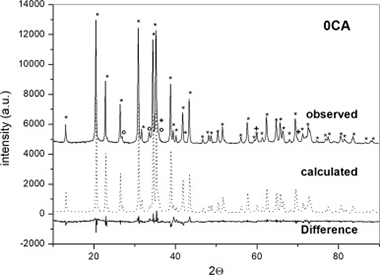

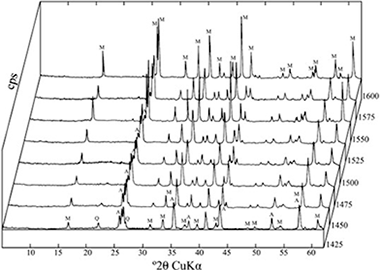

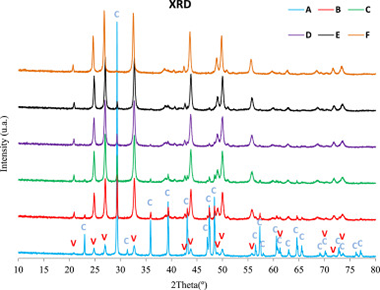

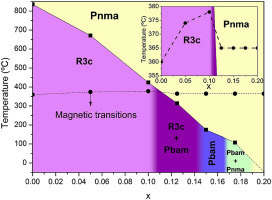

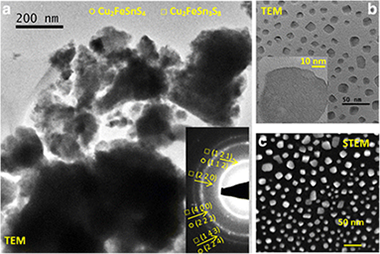

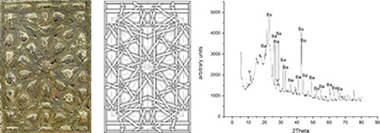

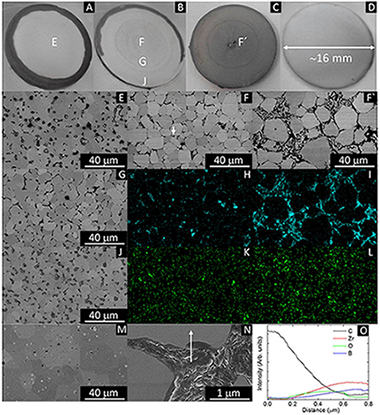

Las pilas de combustible de óxido sólido (SOFCs) son una de las tecnologías más prometedoras y respetuosas con el medio ambiente para la generación de energía eléctrica de forma eficiente a partir de gas natural y otros combustibles fósiles (hidrocarburos). Las SOFCs evitan la combustión directa del combustible, lo que resulta en unas eficiencias de conversión mucho mayores que las que se obtienen mediante métodos termo-mecánicos. Sin embargo, diversas dificultades técnicas relacionadas con el envenenamiento de los ánodos frente a hidrocarburos, problemas de estabilidad química e integridad mecánica de los electrolitos y la alta temperatura de funcionamiento, que reduce la selección de materiales y encarece la tecnología, han impedido la explotación a larga escala de las SOFCs. Un componente de vital importancia es el ánodo, en donde tienen lugar las reacciones electro-catalíticas que convierten la energía química del combustible en corriente eléctrica. Los principales problemas a los que se enfrenta el ánodo están relacionados con (i) su durabilidad, (ii) la difusión del gas y el transporte eléctrico y (iii) la resistencia al envenenamiento químico por carbono y azufre presentes en hidrocarburos. Otro componente crítico es el electrolito, que permite la difusión de iones óxido desde el cátodo hasta el ánodo. Las principales características que debe presentar el electrolito están relacionadas con (i) una elevada conductividad iónica, pero despreciable conductividad electrónica, (ii) unas buenas propiedades mecánicas y (iii) una estabilidad en atmósfera reductora y oxidante. Por ello, si queremos que se generalice la aplicación y el uso de esta tecnología limpia, es necesario que los materiales que se usan como ánodos y electrolitos en SOFCs presenten unas propiedades fisicoquímicas y mecánicas que permitan superar las limitaciones actuales. El proyecto propuesto tiene como objetivo abordar algunos de los problemas expuestos con anterioridad mediante el desarrollo de nuevos ánodos resistentes al envenenamiento en presencia de hidrocarburos y el uso de electrolitos con mejoradas propiedades mecánicas gracias a nuevas arquitecturas. Para ello, vamos a sintetizar por métodos mecano-químicos de una forma barata, versátil y simple nuevos ánodos basados en perovskitas dobles de composición PrBaMn2-jXjO5+δ (PBMXO), con X = Mn, Co, Ni, o Fe y 0 < j < 0.5, a la vez que se diseñarán y fabricarán electrolitos laminados que permitan aumentar su fiabilidad mecánica, sin menoscabo de las propiedades conductoras.

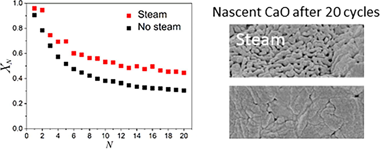

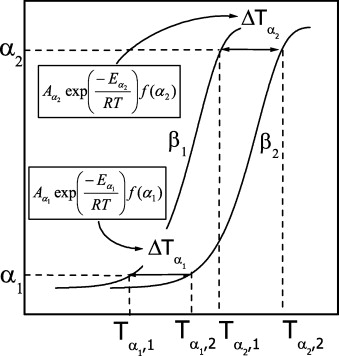

Nuevos materiales para el almacenamiento de Energía Solar Concentrada mediante Calcium-Looping (SOLACAL)

Investigador Principal: Antonio Perejón Pazo / José Manuel Valverde Millán (US)

Periodo: 01-02-2020 / 30-04-2022

Organismo Financiador: Junta de Andalucía

Código: US-1262507

Componentes: María Jesús Diánez Millán, Luis A. Pérez Maqueda, Virginia Moreno García

Grupo de Investigación: Reactividad de Sólidos

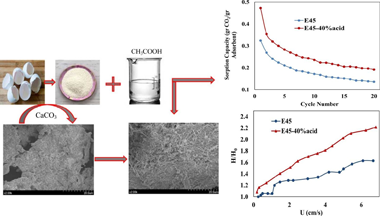

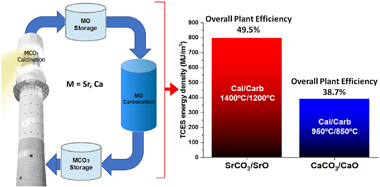

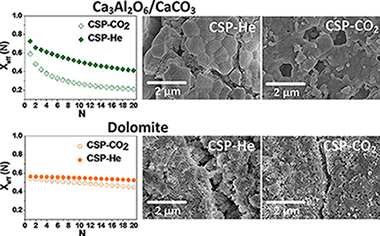

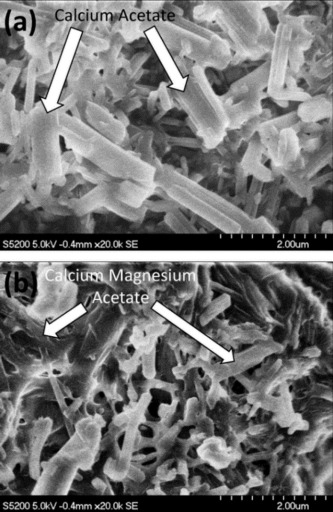

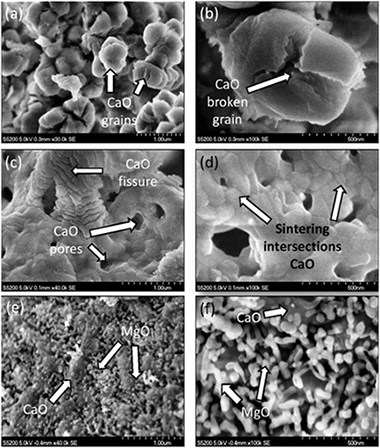

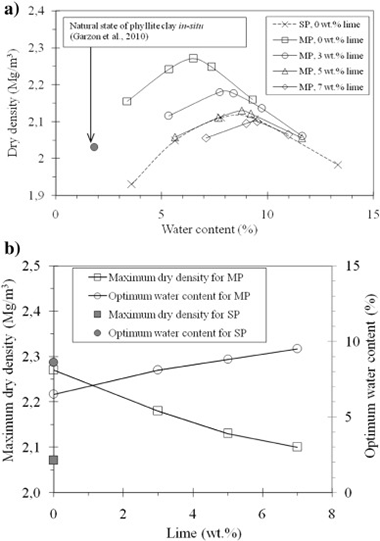

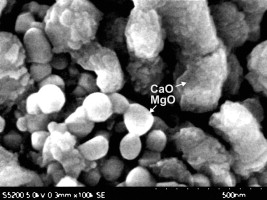

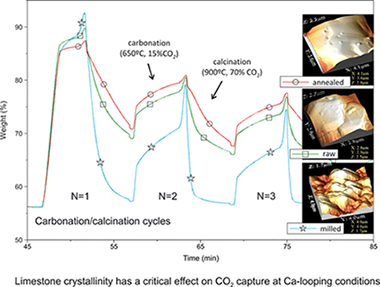

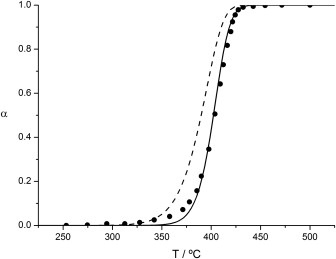

En este proyecto se estudia el comportamiento de nuevos materiales basados en CaO durante ciclos de calcinación/carbonatación (Ca-Looping) en condiciones realistas de almacenamiento de energía en centrales de energía solar concentrada (CSP).

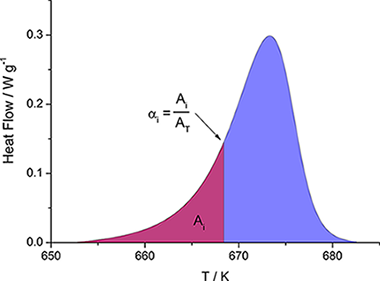

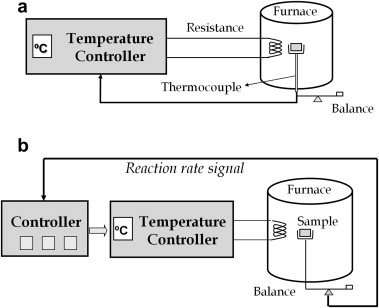

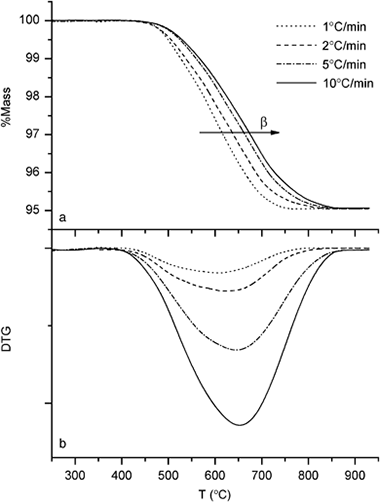

Para simular las condiciones realistas se utilizan equipos termogravimétricos capaces de emplear elevadas velocidades de calentamiento y enfriamiento y diferentes atmósferas de gases. De esta forma, los resultados obtenidos son realmente representativos y podrán ser extrapolados a las condiciones prácticas de operación en plantas CSP.

Se estudia la reactividad multicícilica de muestras de caliza y dolomita, a las que se les realizan tratamientos mecánicos y con ácido acético que pueden mejorar su actividad. Además, se ha demostrado que la presencia de MgO en la dolomita calcinada estabiliza térmicamente el CaO, por lo que se preparan dolomitas sintéticas con distinto contenido en MgO mediante tratamientos mecánicos y coprecipitación con el objeto de encontrar la cantidad óptima de MgO que mejore la actividad multicíclica del CaO. Se estudian asimismo otros materiales con los que se pueda aumentar la temperatura de carbonatación, como el SrCO3 y el BaCO3, lo que permitiría incrementar aún más la eficiencia termoeléctrica de las plantas CSP con almacenamiento termoquímico.

Un aspecto relevante de SOLACAL es que los resultados obtenidos serán transferidos de manera directa a la planta CSP-CaL de demostración que se está construyendo en Sevilla dentro del proyecto H2020 SOCRATCES iniciado en 2018 y coordinado por la Universidad de Sevilla.

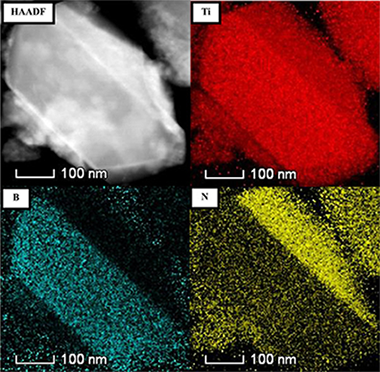

Procesado y Caracterización de Composites Cerámicos con Nanomateriales Laminados Bidimensionales

Investigador Principal: Angela Gallardo López (UEI) / Rosalía Poyato Galán

Periodo: 01-01-2019 / 31-12-2022

Organismo Financiador: Ministerio de Ciencia, Innovación y Universidades

Código: PGC2018-101377-B-I00 "Generación de Conocimiento"

Componentes: Felipe Gutiérrez Mora (UEI), Ana Morales Rodríguez (UEI), Antonio Muñoz Bernabé (UEI), Rocío del Carmen Moriche Tirado (UEI)

Grupo de Investigación: Reactividad de Sólidos

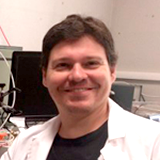

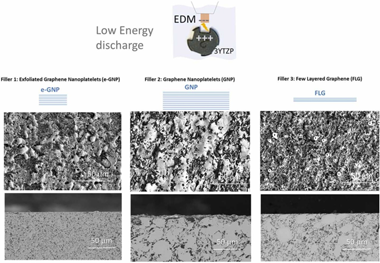

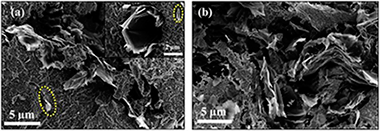

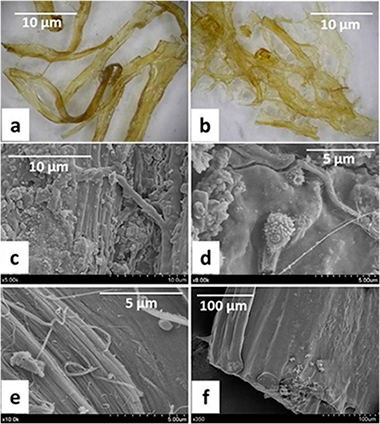

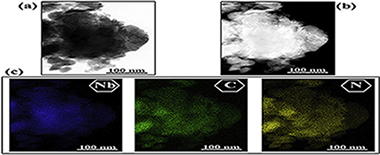

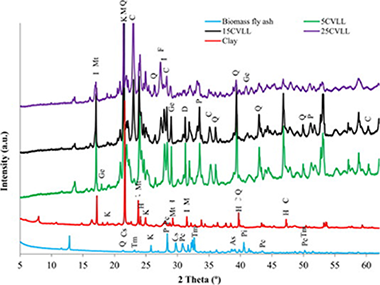

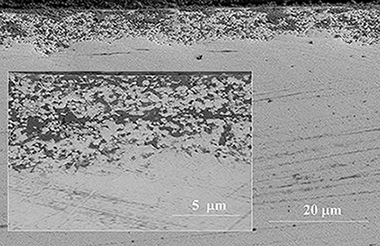

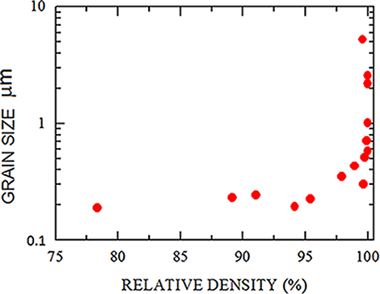

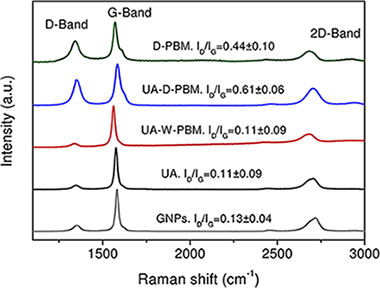

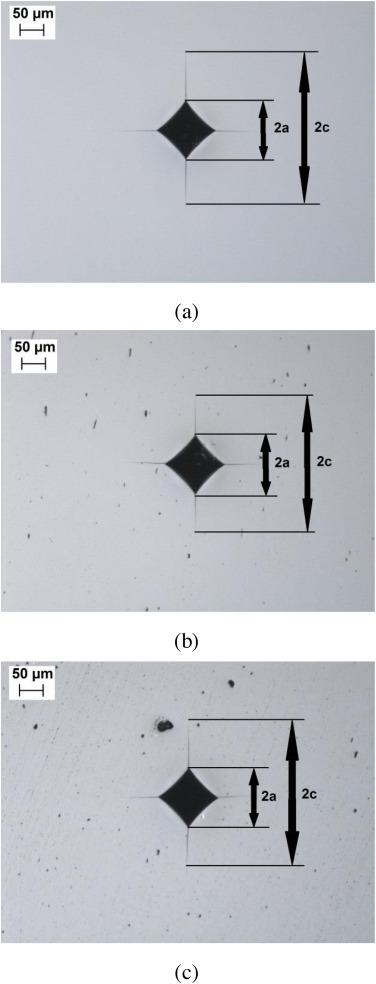

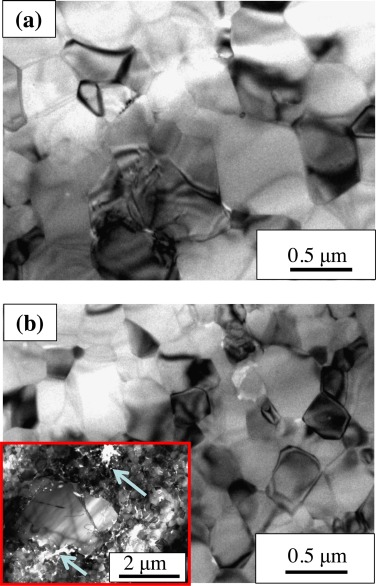

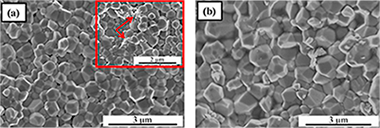

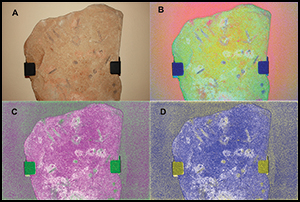

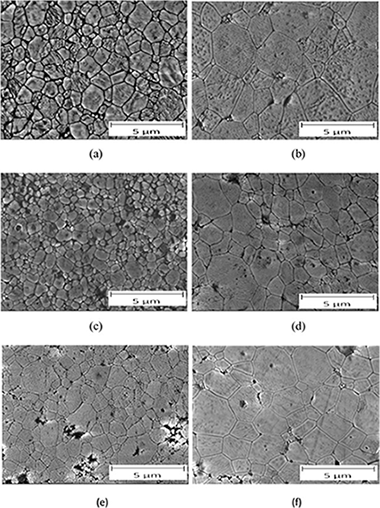

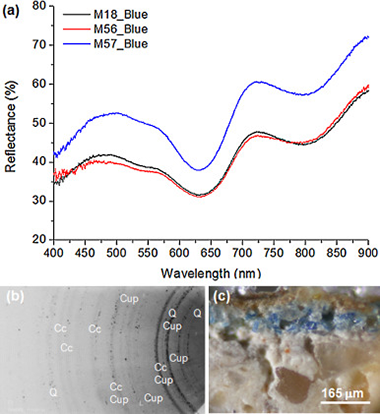

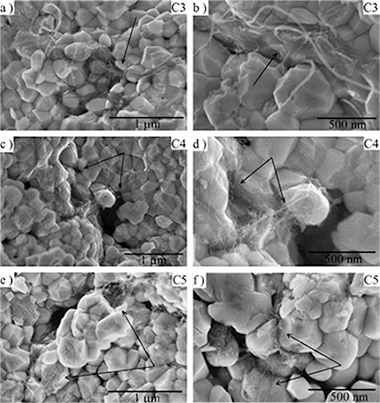

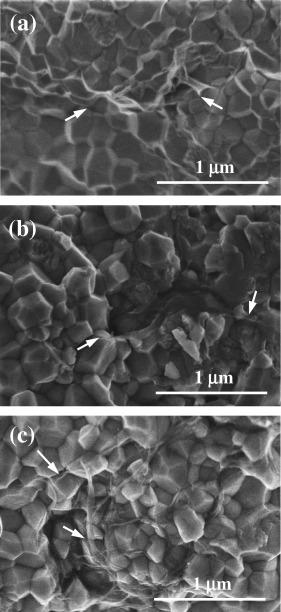

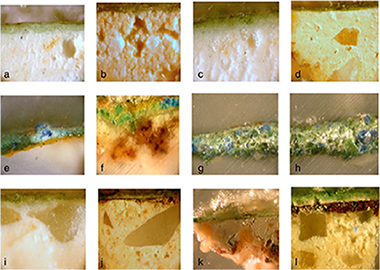

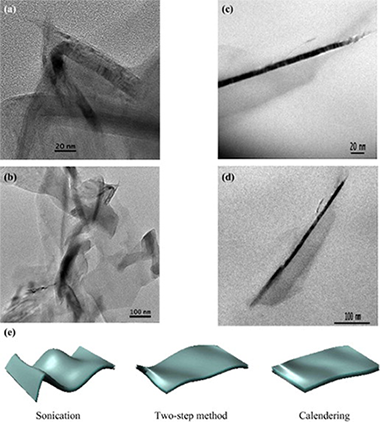

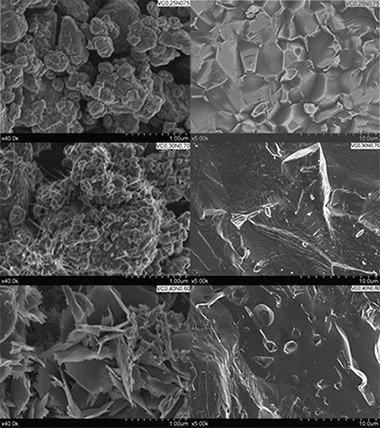

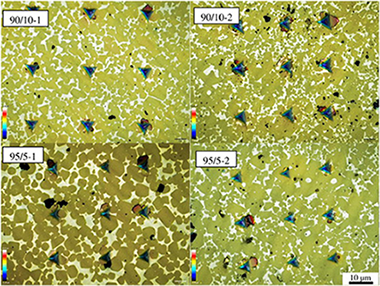

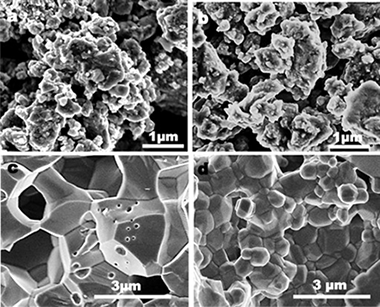

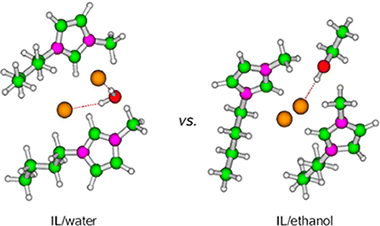

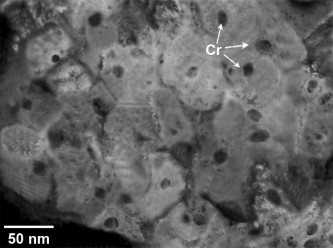

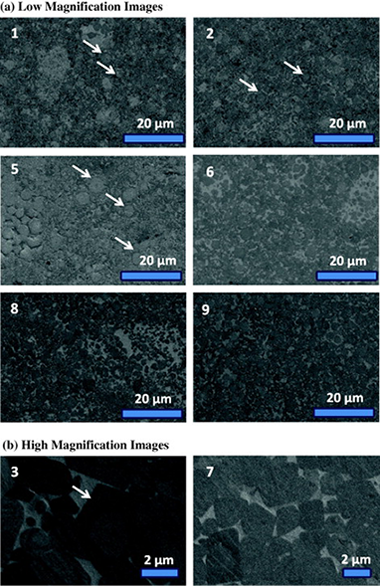

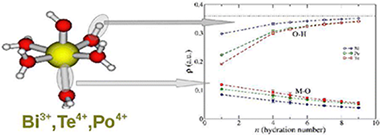

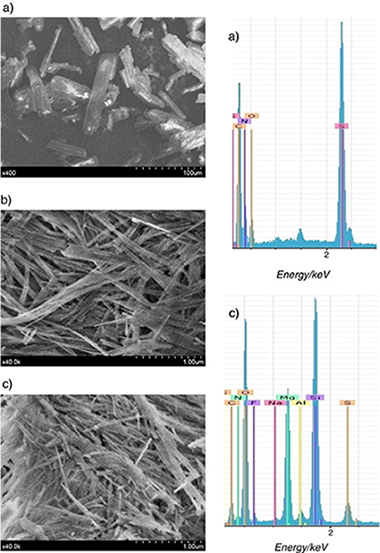

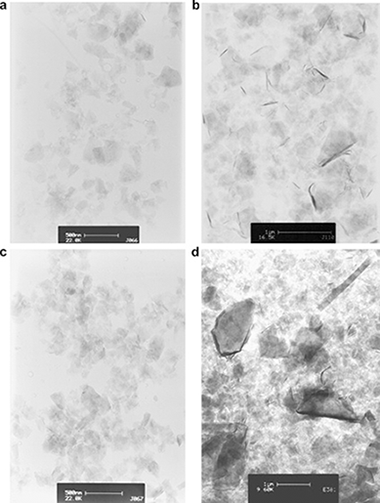

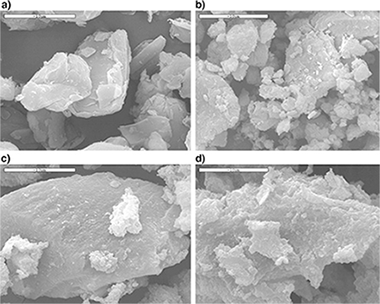

La incorporación de nanomateriales bidimensionales en materiales compuestos de matriz cerámica está aumentando en un esfuerzo para superar la inherente fragilidad de las cerámicas y para conferirles nuevas funcionalidades. Aún existen cuestiones abiertas en este campo en cuanto a resistencia mecánica, tenacidad a la fractura, cinética de crecimiento de fisuras, comportamiento tribológico, papel de fases interfaciales o idoneidad para el electromecanizado, entre otras. Aunque las nanoláminas de grafeno (NLG) se han mostrado como una segunda fase muy adecuada, los nanomateriales inorgánicos análogos al grafeno podrían extender el rango de aplicabilidad de los materiales con grafeno. El uso de nanoláminas de nitruro de boro (NLNB) en estos compuestos es muy prometedor y está prácticamente inexplorado.

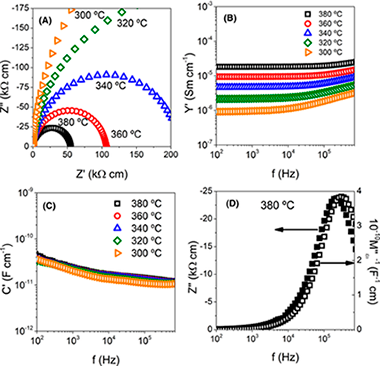

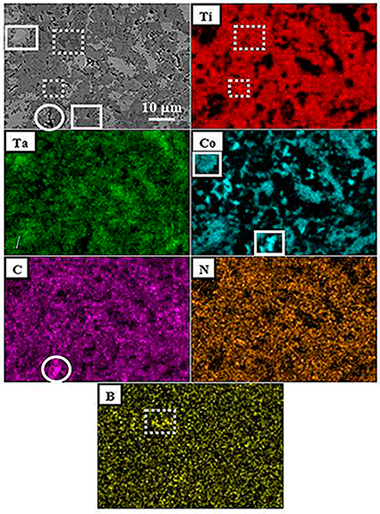

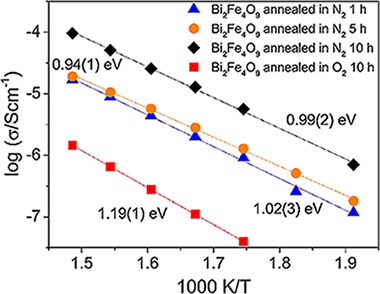

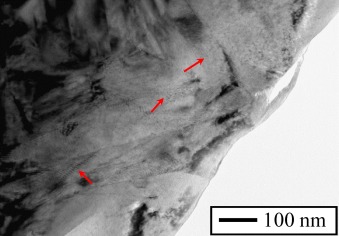

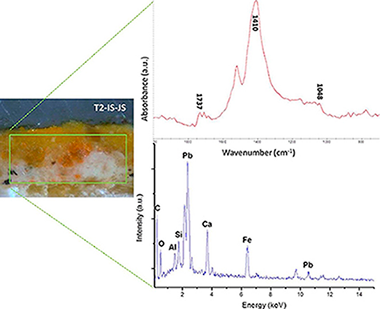

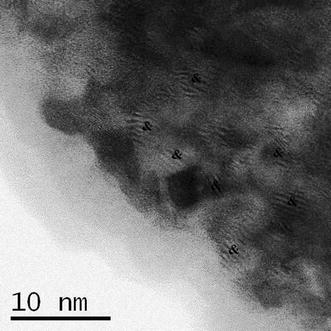

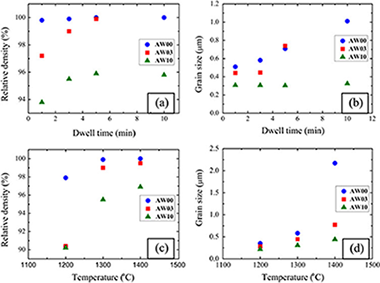

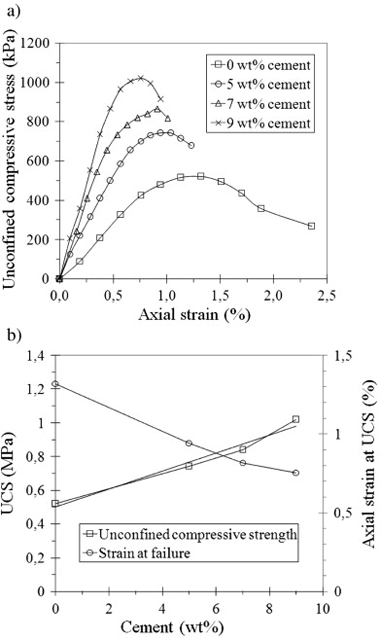

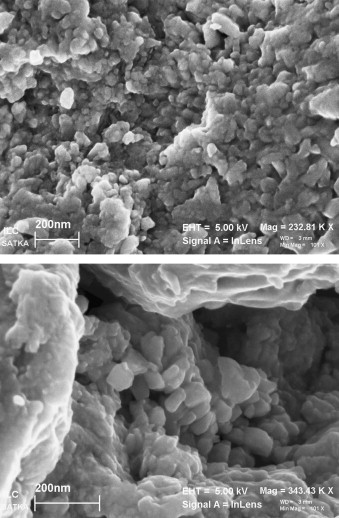

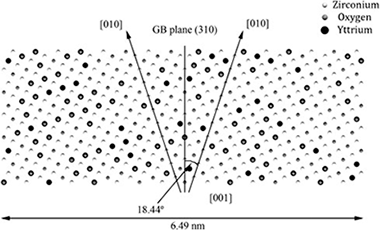

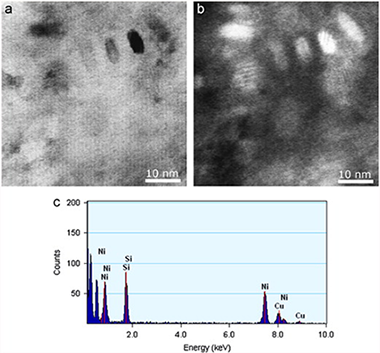

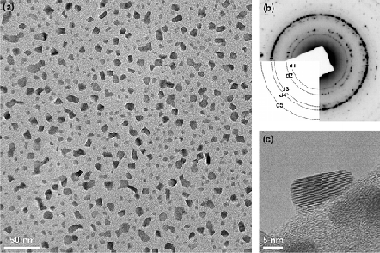

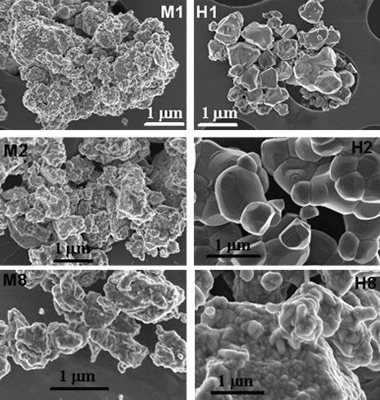

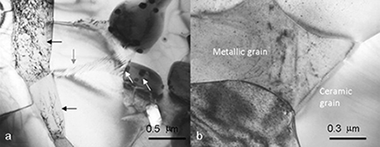

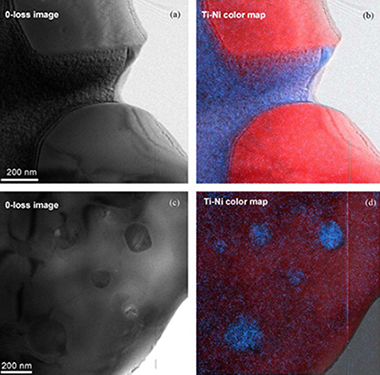

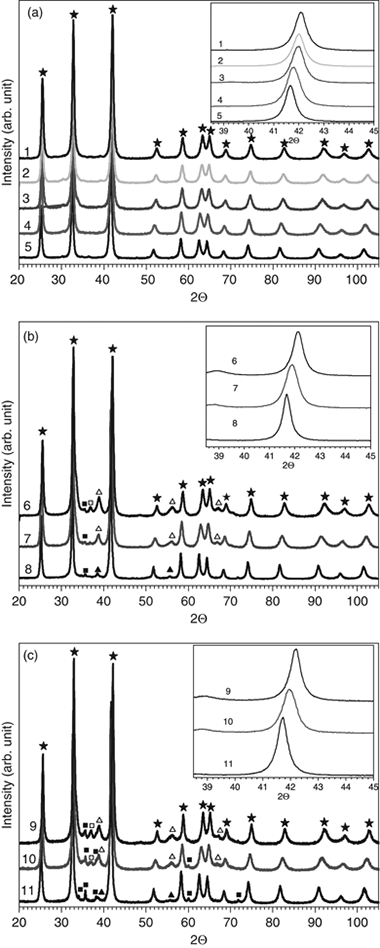

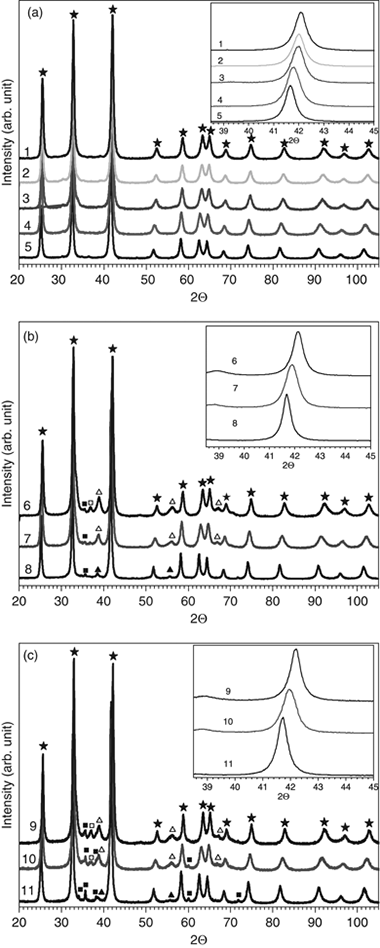

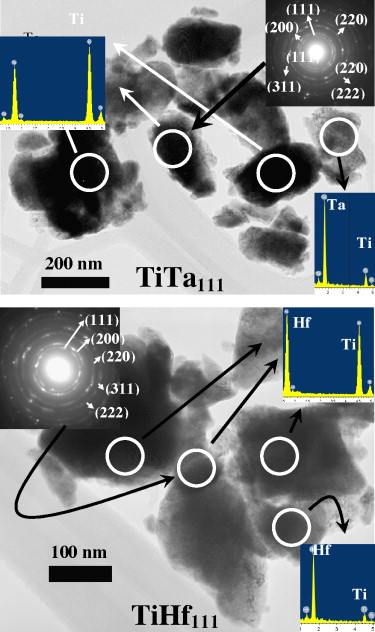

Este proyecto propone un estudio sistemático de materiales compuestos con usos en aplicaciones estructurales y funcionales, con dos matrices de circona estabilizada con itria y dos tipos diferentes de nanomateriales 2D -nanoláminas de grafeno o de nitruro de boro- para profundizar en la comprensión de sus comportamientos mecánico y eléctrico. Con este fin, se fabricarán materiales con matrices de circona tetragonal dopada con 3 %mol de itria y circona cúbica dopada con itria, persiguiendo una microestuctura óptima con una distribución homogénea de los nanomateriales 2D en ambas matrices cerámicas. Se investigarán en profundidad materiales con NLG para dar respuesta a cuestiones abiertas en el conocimiento de estos materiales. La distribución, tamaño e integridad estructural de las NLG se caracterizarán mediante difracción de rayos X, microscopía electrónica de barrido y espectroscopía Raman, y las intercaras entre las NLG y la matriz se caracterizarán mediante microscopía electrónica de transmisión. La resistencia mecánica, resistencia a la rotura, mecanismos de refuerzo y cinética de crecimiento de grano en estos materiales se examinará en profundidad, y se establecerá la mejor combinación de ruta de procesado y contenido de NLG en términos de refuerzo a la matriz. Se realizarán medidas de conductividad eléctrica en materiales con diferentes contenidos de NLG y se evaluará la respuesta al electromecanizado de los materiales eléctricamente conductores. Se realizarán también medidas de conductividad eléctrica en función de la temperatura para describir las posibles variaciones en el tipo de conducción al aumentar el contenido en NLG. Por otra parte, se investigarán materiales con NLNB con el objetivo de obtener una primera aproximación a la comprensión de este sistema. Con este fin, tras la síntesis de las NLNB usando una estrategia de mezcla de disolventes para la exfoliación en fase líquida de nanoláminas a partir de polvo de BN hexagonal, se prepararán polvos con diferentes contenidos de NLNB usando técnicas de procesado de polvo en medio húmedo. La caracterización microestructural de los materiales sinterizados mediante Spark Plasma Sintering" se realizará mediante microscopía electrónica de barrido y de transmisión, difracción de rayos X y espectroscopía Raman. Se estudiarán propiedades como dureza, resistencia a la flexión y resistencia al desgaste, y se realizarán ensayos mecánicos a alta temperatura. Se analizar la conductividad eléctrica en función de la temperatura para esclarecer el efecto de la incorporación de una segunda fase aislante en las fronteras de grano sobre el comportamiento eléctrico de un conductor iónico.

Integración de la tecnología “calcium looping” en plantas solares para el almacenamiento termoquímico de energía

Investigador Principal: Luis A. Pérez Maqueda

Periodo: 01-01-2018 / 30-09-2021

Organismo Financiador: Uniòn Europea

Código: H2020-ENERGY/0373 "Research & Innovation Action"

Componentes: María Jesús Diánez Millán, Pedro Enrique Sánchez Jiménez

Grupo de Investigación: Reactividad de Sólidos

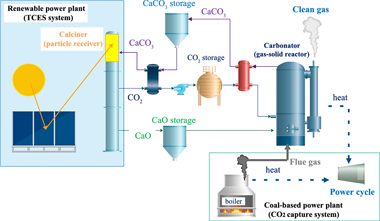

El almacenamiento de energía es uno de los mayores desafíos para aumentar la viabilidad a corto plazo de las plantas de energía solar concentrada (CSP), que generalmente se caracterizan por su intermitencia en la producción de energía. El proceso Ca-Looping (CaL) basado en la reacción reversible de carbonatación/calcinación del CaO es una de las tecnologías más prometedoras para el almacenamiento termoquímico de energía (TCES). La amplia disponibilidad en la naturaleza de piedra caliza (CaCO3) y su bajo precio (<10 € / ton) son factores clave para el despliegue comercial de la tecnología CaL.

SOCRATCES tiene como objetivo demostrar la viabilidad de la integración CSP-CaL mediante la construcción de una planta a escala piloto que utiliza materiales baratos, abundantes y no tóxicos, así como tecnologías actualmente en uso en la industria, como los reactores de lecho fluidizado y los intercambiadores de calor.

El objetivo global de SOCRATCES es desarrollar un prototipo que reduzca los riesgos a la hora de ampliar la tecnología CaL a escala global y resuelva cuestiones abiertas; comprender mejor y optimizar las eficiencias operativas que podrían obtenerse, con el objeto de habilitar plantas de CSP altamente competitivas y sostenibles.

Integración del proceso Ca-looping en centrales de energía solar concentrada para el almacenamiento termo-químico de energía

Investigador Principal: Luis A. Pérez Maqueda

Periodo: 01-01-2018 / 30-09-2022

Organismo Financiador: Ministerio de Ciencia e Innovación

Código: CTQ2017-83602-C2-1-R "Retos de la Sociedad"

Componentes: Pedro Enrique Sánchez Jiménez, María Jesús Diánez Millán

Grupo de Investigación: Reactividad de Sólidos

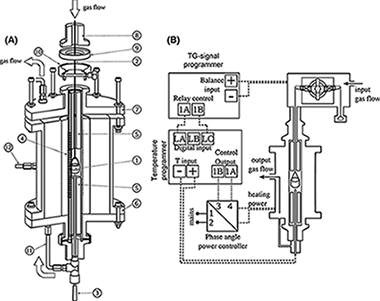

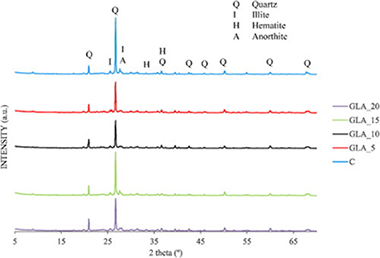

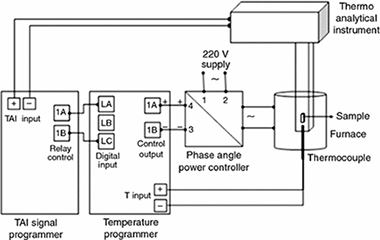

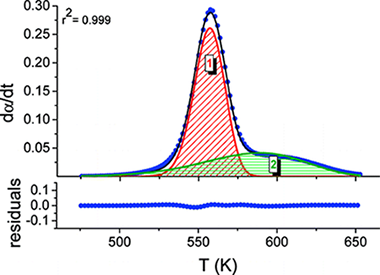

El proyecto solicitado se enmarca dentro del reto general de encontrar nuevas tecnologías de almacenamiento de energía baratas y no contaminantes que permitan superar una de las limitaciones mayores de las fuentes renovables que es la intermitencia en la generación de electricidad. En particular, en este proyecto se propone realizar una integración de la tecnología de Ca-looping en una planta termosolar de concentración. La tecnología de Ca-looping, originariamente propuesta para procesos de captura de CO2, se basa en procesos de carbonatación-descarbonatación (o calcinación) de óxido de calcio-carbonato cálcico repetidos de forma cíclica. Nuestro grupo de investigación ha trabajado durante varios años en esta tecnología, con el objeto de comprender los mecanismos de desactivación conforme se incrementa el número de ciclos. Así, hemos estudiado los mecanismos cinéticos de estos procesos y los cambios microestructurales que tienen lugar a medida que se ciclan los compuestos. En un proyecto coordinado que concluye a finales de año (SOLARTEQH, Retos 2014) hemos realizado ya una propuesta de integración de Ca-Looping para almacenamiento de energía solar. Este proyecto ha dado lugar a una propuesta H2020 (SOCRATCES) aprobada y que comenzará a comienzos del año próximo. En el proyecto CALSOLAR que ahora presentamos se pretende avanzar más en esta idea de integración para incrementar los valores de eficiencia termoeléctrica. El subproyecto 1 realizará las tareas de coordinación de todo el proyecto. Además, en el subproyecto 1 se realizará la selección, preparación y caracterización de los compuestos a utilizar en el proyecto. En este sentido, se trabajará con empresas mineras que nos facilitarán distintas materias primas (principalmente calizas y dolomitas) con diverso grado de pureza y cristalinidad. Se prepararán compuestos con sílicas nanoestructuradas obtenidas a partir de cascarilla de arroz (suministradas por arroceras del valle del Guadalquivir). Se investigarán compuestos preparados a partir de escorias de acerías (suministrados por dos empresas del sector afincadas en Andalucía) que son ricos en calcio para su aplicación en ciclos de almacenamiento termoquímico. En el subproyecto, se diseñará y construirá un equipo termogravimétrico que permita realizar experimentos en las condiciones realistas de los ciclos de almacenamiento térmico. Así el equipo permitirá trabajar en condiciones de presión absoluta controlada de CO2 y en vapor sobrecalentado. En dicho instrumento se realizarán los ciclos de almacenamiento y se estudiarán las condiciones óptimas de dichos ciclos. Se investigarán los mecanismos cinéticos de carbonatación y descarbonatación y se estudiarán los cambios microestructurales durante el ciclado. El equipo de investigación está compuesto por personal con gran experiencia en las tareas propuestas y se cuenta con la participación de investigadores extranjeros con gran experiencia en reacciones sólido-gas y en caracterización microestructural por microscopía de alta resolución. Además, participa una investigadora de la empresa Abengoa con extensa experiencia en almacenamiento termoquímico en plantas solares. Se trabajará en este subproyecto de forma totalmente coordinada con los investigadores del subproyecto 2 con idea de establecer conjuntamente las condiciones de proceso óptimas. Finalmente, los resultados obtenidos del proyecto podrán demostrarse en la planta piloto que se construye en el marco del proyecto H2020 SOCRATCES

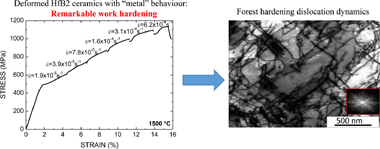

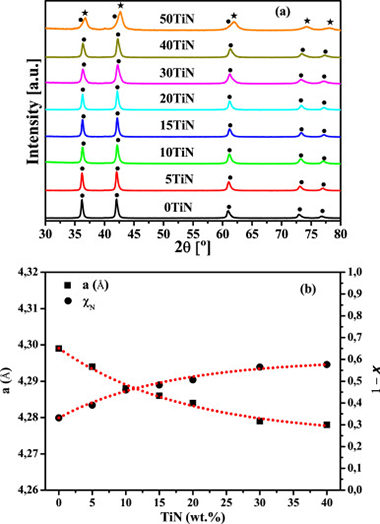

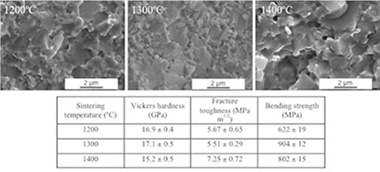

Cerámicas Nanoestructuradas a Base de Carburo de Boro y Nitruro de Titanio para Aplicaciones Estructurales

Investigador Principal: Diego Gómez García / Arturo Domínguez Rodríguez

Periodo: 01-01-2016 / 31-12-2020

Organismo Financiador: Ministerio de Economía y Competitividad

Código: MAT2015-71411-R

Componentes: Francisco L. Cumbreras Hernández, Felipe Gutíerrez Mora, Ana Morales Rodríguez

Grupo de Investigación: Propiedades mecánicas, modelización y caracterización de cerámicos avanzados

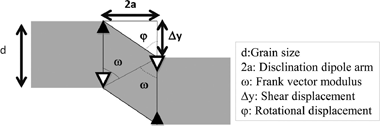

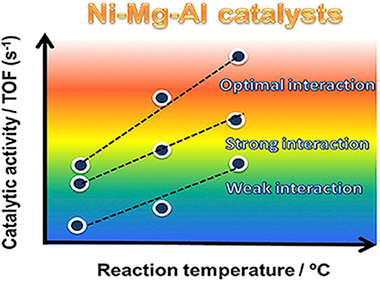

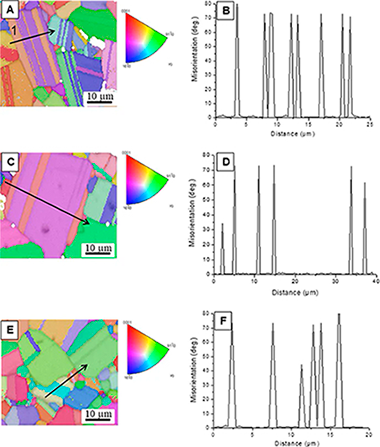

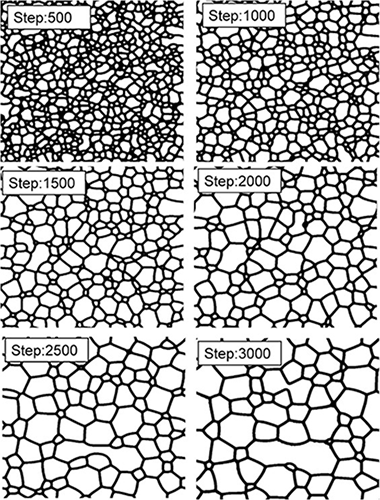

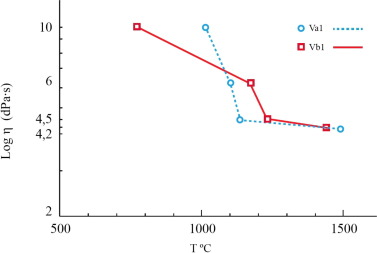

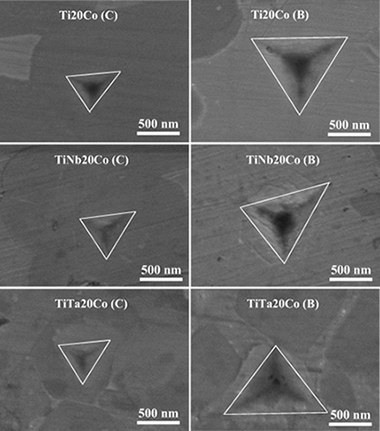

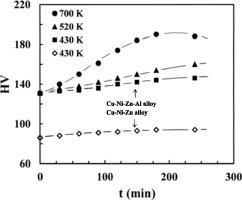

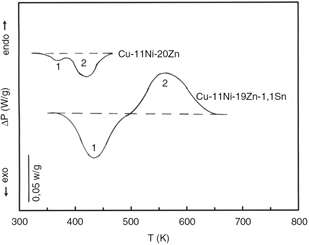

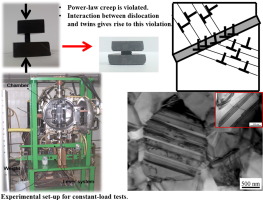

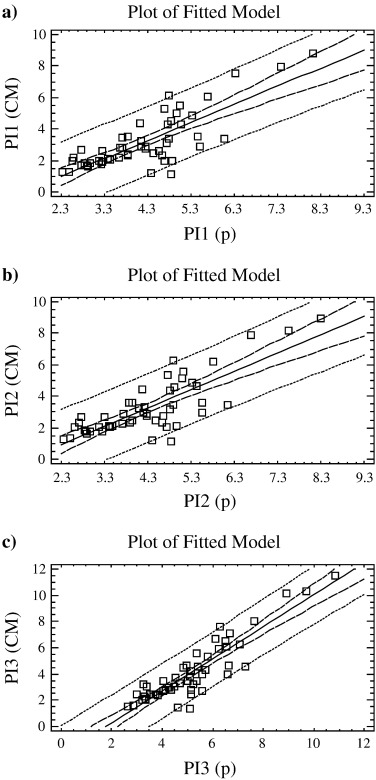

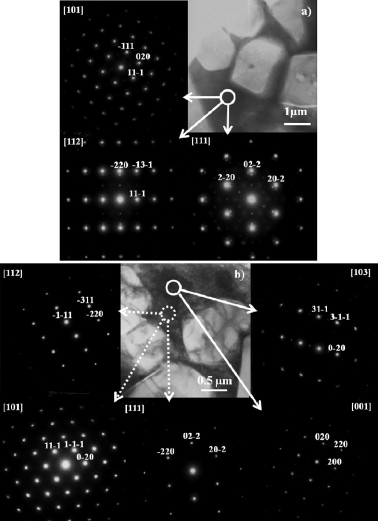

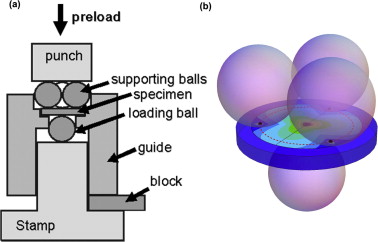

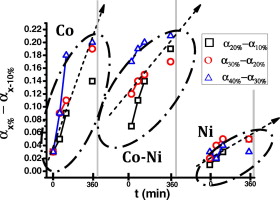

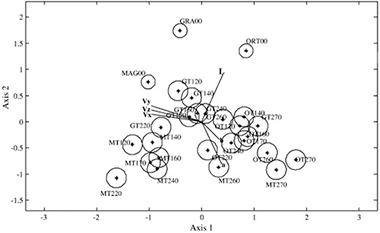

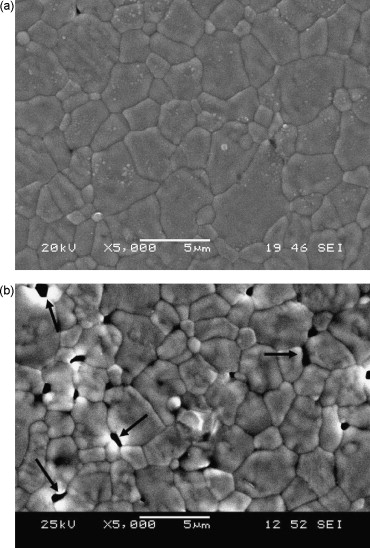

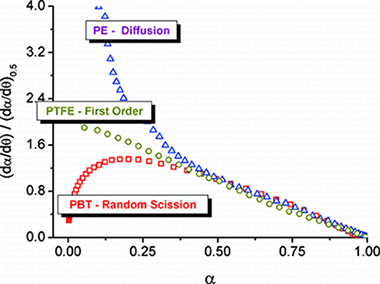

El proyecto tiene como misión la fabricación de forma controlada científicamente de nanocerámicos de carburo de boro y de nitruro de titanio mediante la técnica de chispa de plasma. Se estudiarán las propiedades mecánicas de ambos cerámicos a temperatura ambiente (dureza y tenacidad), así como su plasticidad a alta temperatura (resistencia a la fluencia, deformación a velocidad constante).

Se pretende estudiar la influencia de la microestructura en la respuesta mecánica, así como dilucidar los mecanismos que controlan la plasticidad (particularmente la interacción de dislocaciones con maclas). Los resultados se modelarán analíticamente o mediante simulación a escala mesoscópica (vía modelos de campos de fases).

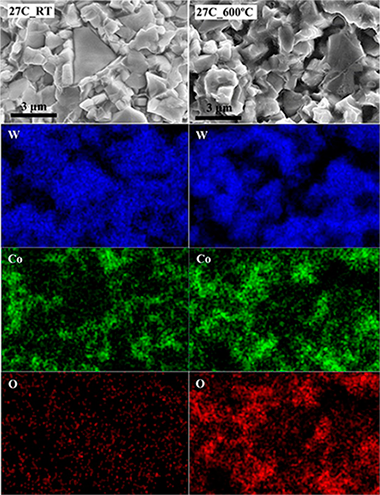

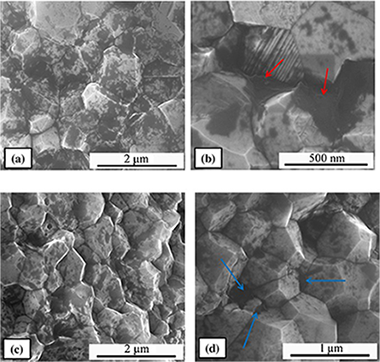

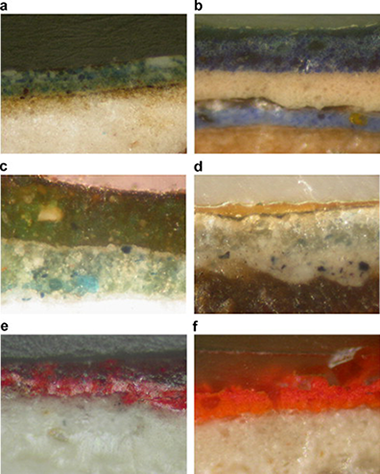

Procesado y caracterización microestructural, mecánica y eléctrica de compuestos cerámica-grafeno

Investigador Principal: Angela Gallardo López (UEI) / Rosalía Poyato Galán

Periodo: 01-01-2016 / 31-12-2018

Organismo Financiador: Ministerio de Ciencia e Innovación

Código: MAT2015-67889-P

Componentes: Antonio Muñoz Bernabé, Felipe Gutiérrez Mora, Ana Morales Rodríguez

Grupo de Investigación: Propiedades mecánicas, modelización y caracterización de cerámicos avanzados

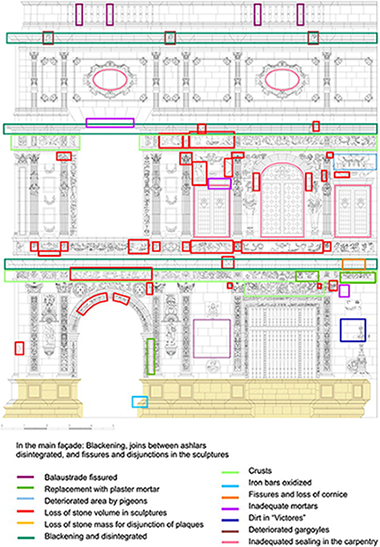

En la actualidad se plantean interesantes expectativas sobre los compuestos cerámica/grafeno, propuestos para aplicaciones en catálisis, almacenamiento y conversión de energía, protección del medio ambiente y biotecnología. Pero aún se requieren importantes esfuerzos para dar respuesta a cuestiones abiertas. Hay que incidir en aspectos como la resistencia a la cizalla de las intercaras cerámica-grafeno -esencial para asegurar la transferencia de carga efectiva sobre las láminas de grafeno-, la distribución homogénea del grafeno en la matriz cerámica y la relación de tamaños entre matriz y refuerzo, para maximizar el aumento de tenacidad y de conductividad eléctrica, así como también explorar sus propiedades mecánicas a alta temperatura.

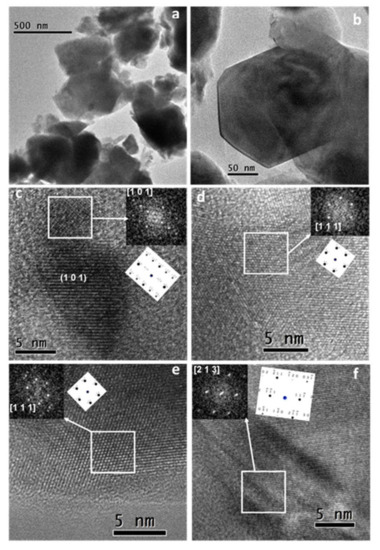

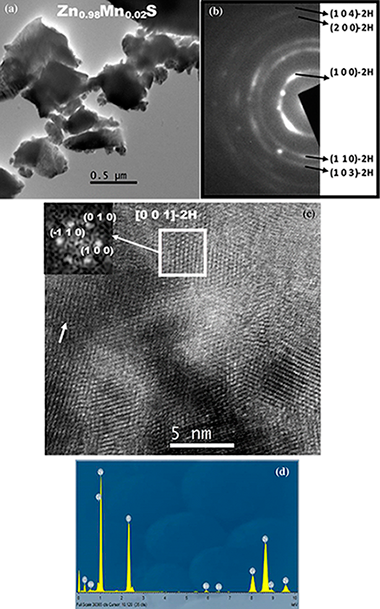

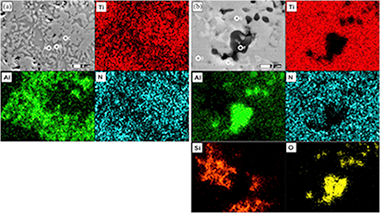

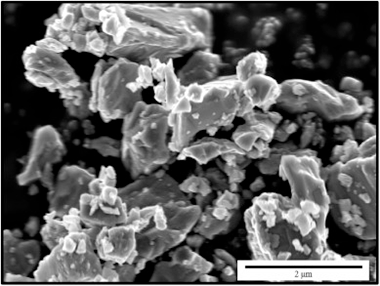

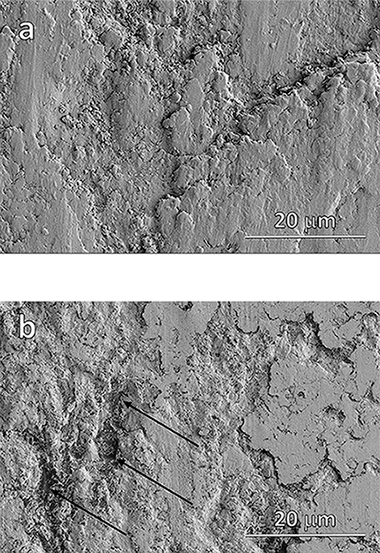

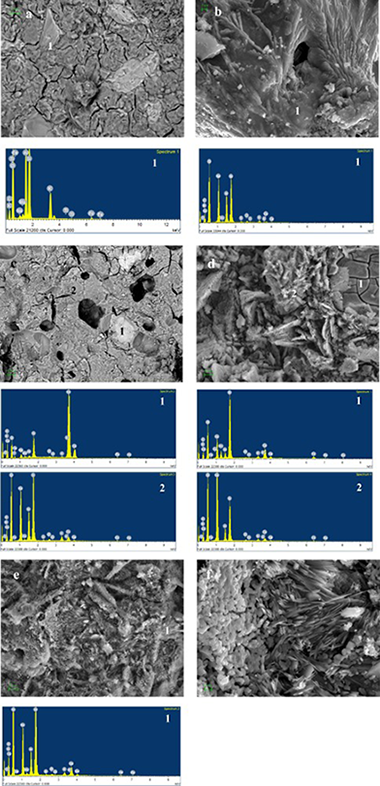

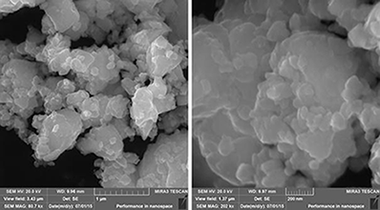

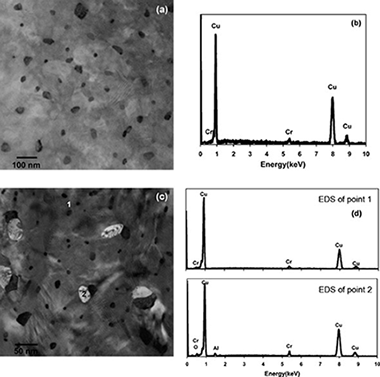

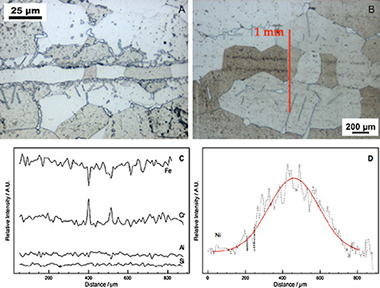

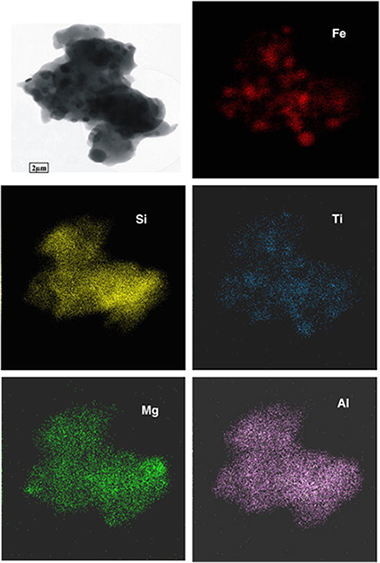

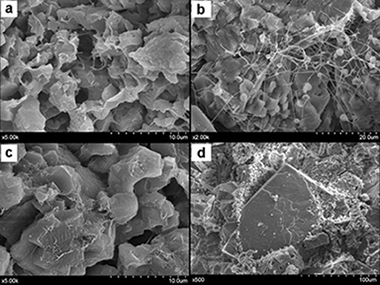

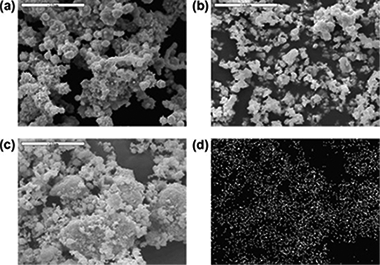

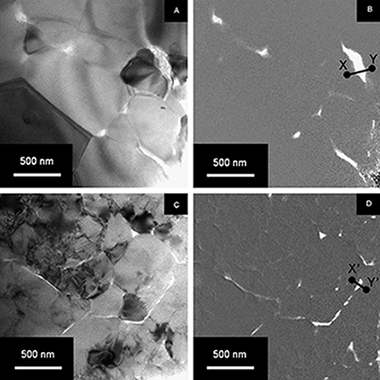

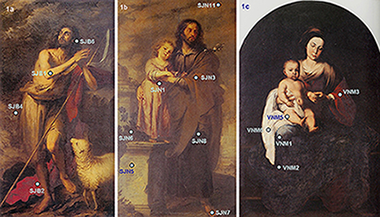

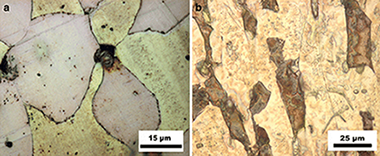

En este proyecto se plantea un estudio sistemático de compuestos de matrices cerámicas con grafeno, desde la fabricación hasta la caracterización microestructural, mecánica y eléctrica, con el objetivo de mejorar la comprensión de los mecanismos que controlan estas propiedades al incorporar nanoestructuras de grafeno a una matriz cerámica. Se procesarán compuestos de dos matrices cerámicas diferentes, de alúmina y de circona tetragonal dopada con óxido de itrio (3YTZP), con grafeno mediante técnicas coloidales, prestando especial atención a la dispersión del grafeno en la matriz cerámica, aspecto no exento de dificultades y que es clave para conseguir la mejora de las propiedades. La sinterización se realizará en un horno de descarga de plasma (SPS, spark plasma sintering) de última generación, optimizando las condiciones para conseguir compuestos densos y de tamaño de grano nanométrico. Para el análisis microestructural se utilizarán técnicas como la difracción de rayos X, la espectroscopía Raman, y la microscopía electrónica de barrido y transmisión. Con ellas se evaluarán las fases cristalográficas presentes, el tamaño de grano, la distribución de las nanoestructuras de grafeno, etc.

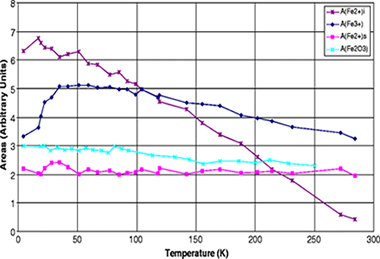

Desde el punto de vista del diseño de materiales avanzados, es fundamental investigar la relación entre microestructura y propiedades mecánicas y eléctricas. Las propiedades mecánicas a temperatura ambiente (dureza, tenacidad a la fractura y resistencia a flexión) se abordarán mediante indentación y ensayos de flexión, a escalas macro y microscópica. A alta temperatura, se estudiará la deformación plástica de los compuestos cerámica-grafeno mediante ensayos de fluencia en atmósferas controladas. También se estudiará el comportamiento tribológico de los compuestos y se evaluará su conductividad eléctrica, una de las propiedades más interesantes ya que se modifica de forma notoria como resultado de la incorporación del grafeno a estos sistemas cerámicos. La respuesta eléctrica se analizará en un amplio rango de temperaturas, bien mediante espectroscopía de impedancia compleja, bien mediante medidas de conductividad en corriente continua en el caso de los compuestos menos resistivos.

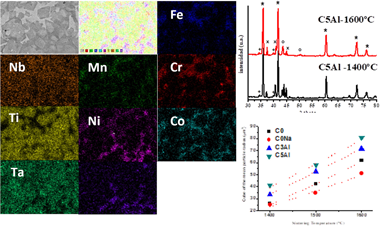

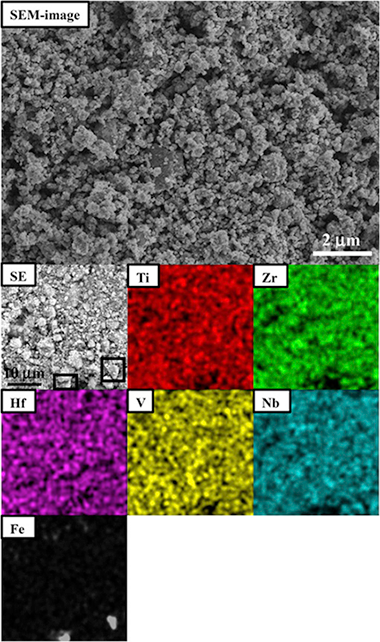

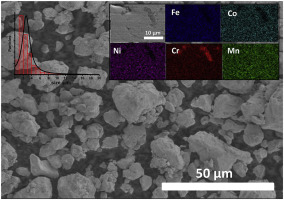

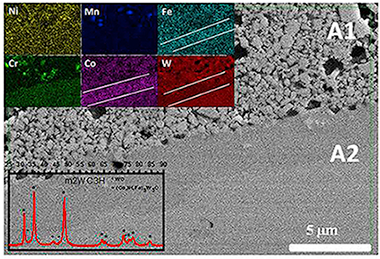

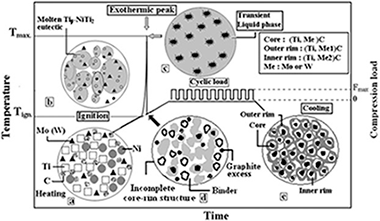

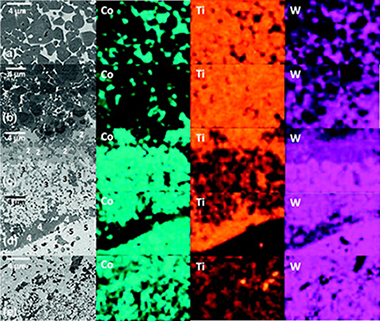

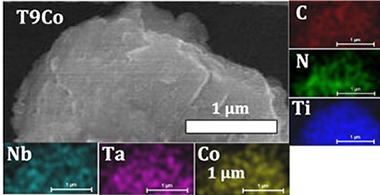

Desarrollo de cermets con aleaciones de alta entropía de mezcla como fase ligante para aplicaciones de mecanizado

Investigador Principal: Francisco José Gotor Martínez

Periodo: 01-01-2015 / 31-12-2018

Organismo Financiador: Ministerio de Economía y Competitividad

Código: MAT2014-52407-R

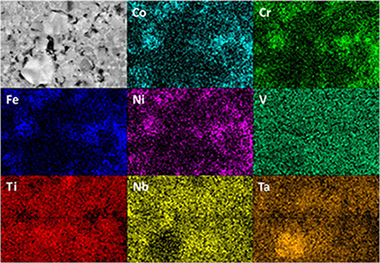

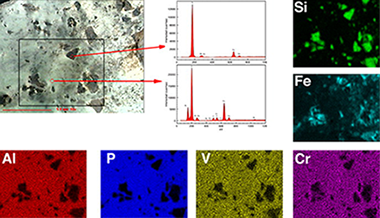

Componentes: José Manuel Córdoba Gallego, María Dolores Alcalá González, Pedro José Sánchez Soto, Concepción Real Pérez, María Jesús Sayagués de Vega

Grupo de Investigación: Materiales Avanzados, Reactividad de Sólidos

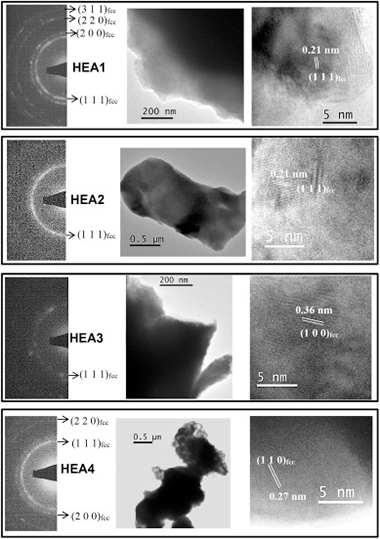

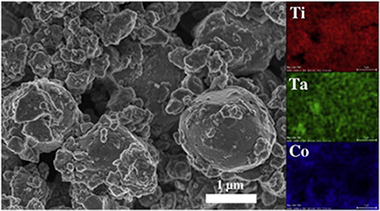

El mecanizado es parte esencial de los procesos de fabricación empleados en muchos sectores industriales y posee una importante implicación económica, al representar una proporción significativa del coste total de fabricación. El éxito del mecanizado depende de múltiples factores, entre los que destaca la herramienta de corte utilizada. El mecanizado de alta velocidad y de los materiales denominados difíciles de mecanizar, como las superaleaciones empleadas en la fabricación de motores a reacción, imponen unas condiciones extremas de trabajo caracterizadas por altas temperaturas, presiones y tensiones, que pueden provocar el fallo prematuro en servicio de la herramienta de corte. Además, el deterioro de la herramienta, debido a un excesivo desgaste y deformación, hace que resulte difícil mantener las tolerancias y la integridad de la superficie mecanizada, lo que compromete seriamente las propiedades de fatiga de la pieza y, por tanto, su aplicabilidad y vida útil. La importante implicación económica de este tipo de mecanizados hace que la industria europea se haya marcado como objetivo primordial mejorar la productividad de estos procesos e incrementar su precisión y calidad, promoviendo la búsqueda de nuevos materiales para herramienta que se adapten mejor a estos nuevos requerimientos.

De los materiales para herramienta que se emplean en la actualidad, los cermets son los que mejor se adaptarían a las exigencias de estos mecanizados, ya que poseen una alta resistencia al desgaste, una estabilidad química elevada y una resistencia mecánica que se mantiene a alta temperatura. Pero, sería necesario mejorar ostensiblemente la tenacidad de fractura y la tolerancia al daño hasta valores próximos a los que presentan los carburos cementados. Durante los últimos años se ha producido un continuado proceso de optimización de los cermets, modificando principalmente la microestructura y la composición química de las fases cerámicas empleadas. En el proyecto MAT2011-22981 demostramos que los cermets denominados de solución sólida completa, caracterizados por poseer una única fase cerámica homogénea formada por un carbonitruro complejo, permiten alcanzar una buena combinación de dureza y tenacidad y una alta resistencia a la oxidación.

En el presente proyecto, que puede considerarse como complementario al MAT2011-22981, se pretende mejorar aún más las propiedades de los cermets, pero actuando en este caso sobre la fase ligante, que es en última instancia la principal causante de la cohesión y la tenacidad del material. Las aleaciones de alta entropía de mezcla se postulan como candidatas idóneas para sustituir a las fases ligantes actuales, ya que presentan una alta resistencia, una buena ductilidad y un excelente comportamiento mecánico a elevadas temperaturas. El objetivo general del presente proyecto se centra en el desarrollo de cermets de solución sólida completa con una fase metálica ligante formada por aleaciones de alta entropía de mezcla. Los materiales que se desarrollarán poseerán una microestructura sencilla, similar a la que presentan los actuales carburos cementados, pero con una elevada complejidad composicional, ya que ambas fases constituyentes (cerámica y metálica) serán soluciones sólidas con un número importante de componentes, al menos cinco. Con estos nuevos cermets, se pretenden mantener las propiedades óptimas que presentan actualmente y mejorar aquellas que limitan su uso potencial en los mecanizados más exigentes.

Almacenamiento TErmoQuímico Híbrido de energía SOLAR concentrada SOLARTEQH

Investigador Principal: Luis Allan Pérez Maqueda

Periodo: 01-01-2015 / 31-12-2017

Organismo Financiador: Ministerio de Economía y Competitividad

Código: CTQ2014-52763-C2-1-R

Componentes: María Jesús Diánez Millán, José Manuel Criado Luque

Grupo de Investigación: Reactividad de Sólidos

Actualmente existen proyectos dentro de los prgramas Sunshot (USA) y FP7 (UE) en los que se analiza la viabilidad de lechos fluidizados de sólidos granulados para el almacenamiento químico de energía solar concentrada. Uno de los materiales considerados es la caliza natural (CaCO3), abundante y barata. Usando una mezcla CO2/aire en porcentajes relativos adecuados a las temperaturas de trabajo (600ºC-900ºC) se descarbonataría el CaCO3 mediante reacción endotérmica en períodos de elevada irradiación o se carbonataría el CaO liberando calor cuando la temperatura descendiese por debajo de un cierto valor. Mediante la variación del %CO2 en el gas de fluidización se provocarían las reacciones de descarbonatación-carbonatación según se desee reducir o aumentar la temperatura del lecho en función de la intensidad de radiación solar y de la demanda. Este control ayudaría a paliar el efecto de la variabilidad de la intensidad de radiación solar sobre la transferencia de calor al ciclo de vapor para la producción de corriente eléctrica. Además de tratarse de un almacenamiento de energía sin pérdidas, la densidad energética del CaCO3 (~1 MWhr/m3) es mayor que la de las sales fundidas actualmente empleadas en plantas comerciales (0.25-0.40 MWhr/m3), siendo además la caliza un material no corrosivo, no degradable y que permitiría operar a mayores temperaturas y aumentar así la eficiencia de conversión termoeléctrica. No obstante, la fluidización de la caliza es altamente heterogénea, formándose canales de gas y agregados no fluidizables en el lecho que reducirían en gran medida la transferencia térmica, la eficacia de contacto sólido/gas y por tanto el grado de conversión. Por otra parte, se han puesto en marcha plantas piloto basadas en almacenamiento térmico en lechos fluidizados de sólidos granulados inertes de alta capacidad calorífica como la arena o el carburo de silicio que presentan un estado de fluidización uniforme con alta transferencia térmica. Estos sistemas poseen inevitables pérdidas térmicas y son necesarios grandes volúmenes para garantizar el suministro de calor al ciclo de vapor en períodos de baja radiación. Nuestro proyecto se basa en complementar de manera sinérgica las ventajas del almacenamiento térmico en lechos fluidizados de sólidos inertes con el químico mediante lechos fluidizados de mezclas de sólidos inertes fluidizables con otros basados en CaO (arena y caliza naturales por ejemplo). En nuestro trabajo evaluaremos la transferencia y almacenamiento de energía solar concentrada de estos sistemas híbridos. El plan de trabajo contemplará acotar las condiciones óptimas de concentración de CO2 en el gas de fluidización y proporción de arena/caliza en función de la temperatura para las que la eficacia de almacenamiento se viera optimizada. Estudiaremos las propiedades físicas y químicas de mezclas de arena/caliza y los parámetros físicos que favorezcan la transferencia y almacenamiento de calor en función de la intensidad de la radiación solar. Así mismo se explorarán métodos de estabilización térmica del CaO con el objeto de incrementar la reversibilidad de carbonatación/calcinación en condiciones prácticas. De manera paralela se desarrollará un modelo termodinámico que incluya aquellos procesos que afectan a la eficiencia energética del mismo y sirva para establecer parámetros óptimos de operación con el objetivo final de transferencia al sector tecnológico para lo que se contará con el apoyo de Abengoa Solar.

Nanogeneradores ferroeléctricos basados en polímeros para aplicaciones en generación de energía y sensores

Investigador Principal: Pedro E. Sánchez Jiménez

Periodo: 01-10-2014 / 30-09-2016

Organismo Financiador: Junta de Andalucia

Código: TAPOST-134. Programa Talent HUB

Componentes:

Grupo de Investigación: Reactividad de Sólidos

La generación de energía a partir de fuentes ambientales ha generado un enorme interés pues ofrece una slución energética para aplicaciones de bajo consumo tales como sensores inalámbricos, dispositivos portátiles, implantes biomédicos o dispositivos de monitorización estructural o medioambiental. Por ejemplo, se considera que el número de dispositivos de uso diario conectados a internet se estima 50.000 millones para el año 2020. La mayoría de estos dispositivos (“internet of things”) son de un tamaño muy reducido o se encuentran integrados en otros equipos mayores. La manera más sostenible de proporcionar energía a estos dispositivos es la autogeneración, de tal manera que no sea necesario recargarlos durante toda su vida útil. En este sentido, la generación de energía a partir de vibraciones ambientales es particularmente atractiva pues es una fuente de disponibilidad casi ilimitada y extraordinariamente barata al producirse por fuentes tales como las partes móviles de equipos, fluidos o incluso personas. Los generadores piezoeléctricos de escala nanométrica, también conocidos como nanogeneradores, son capaces de convertir vibraciones a pequeña escala en energía eléctrica, y por tanto son candidatos para reemplazar baterías que requieran una recarga constante, las cuales no se redimensionan con facilidad a muy pequeño tamaño La generación de energía mediante nanogeneradores piezoeléctricos es una tecnología emergente y esta propuesta se basa en la preparación de materials novedosos polímero-cerámica con propiedades piezoeléctricas que puedan utilizarse para diseñar dispositivos baratos, medioambientalmente limpios y que se puedan integrar fácilmente como nanogeneradores en dispositivos electrónicos.

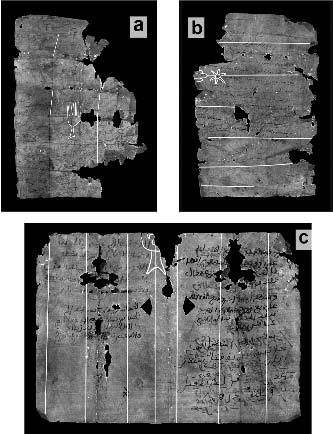

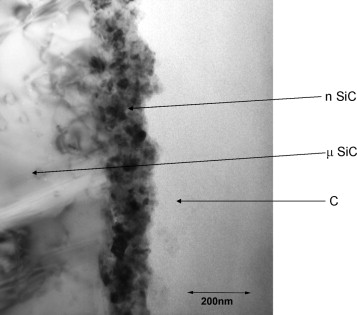

Síntesis y caracterización de materiales cerámicos no oxídicos obtenidos por descomposición de precursores poliméricos

Investigador Principal: Pedro E. Sánchez Jiménez

Periodo: 16-05-2014 / 15-05-2016

Organismo Financiador: Junta de Andalucia

Código: TEP-1900

Componentes: Antonio Perejón Pazo, Cristina García Garrido

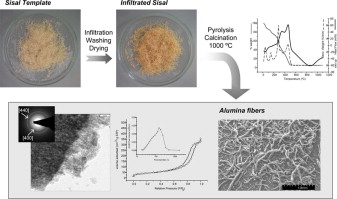

Grupo de Investigación: Reactividad de Sólidos

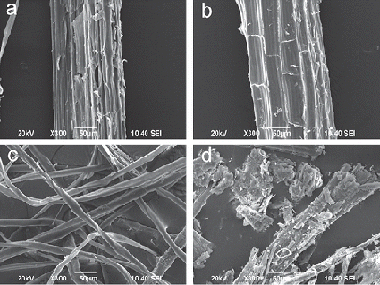

En los últimos años se ha incrementado sustancialmente el interés por las cerámicas derivadas de polímeros debido al amplísimo abanico de potenciales propiedades que presentan. Este tipo de cerámicas son más conocidas por las siglas PDC (polymer derived ceramics). Estos materiales se obtienen como producto de la descomposición térmica de un precursor polimérico, que deja como residuo una cerámica, habitualmente de naturaleza no oxídica, de tipo SiC, Si3N4, BN, etc. Las PDCs presentan una serie de propiedades termomecánicas y eléctricas de gran interés, así como una elevada resistencia a la temperatura y a la oxidación que los hacen muy adecuados para aplicaciones en condiciones extremas. Así, se han propuesto numerosas aplicaciones que abarcan desde la nanotecnología a la aeronáutica. Una importante ventaja es que dichas propiedades dependen en gran medida de las características químicas del precursor polimérico de partida así como del procedimiento de conversión en cerámica. Por tanto, es posible dirigir las propiedades de la cerámica final seleccionando cuidadosamente el precursor y las condiciones experimentales de ceramización. Además, las temperaturas necesarias para obtener materiales cerámicas por esta vía son relativamente suaves si se comparan con las necesarias mediante procesado cerámico convencional por consolidación de polvos cerámicos. Sin embargo, estos materiales presentan una limitación para ciertas aplicaciones debido a que durante la transformación en cerámica se producen defectos o fracturas que pueden llegar a hacer inservible el material. A pesar de su importancia, existen pocos estudios sistemáticos en los que se haya abordado la influencia de las condiciones de preparación en las propiedades finales de las cerámicas. En concreto, se planea utilizar los métodos de control inteligente de temperatura para el procesado de estos precursores poliméricos precerámicos. Esta metodología permite controlar con gran precisión las condiciones experimentales y ha demostrado ser muy útil para de controlar la estructura y microestructrura de productos preparados a partir de transformaciones térmicas de precursores. Así mediante el uso de los métodos de control inteligente de temperatura pretendemos obtener PDC libres de defectos, estudiar la influencia de las condiciones de la preparación en la nanoestructura de los productos y ahondar en el conocimiento de los procesos de conversión polímero-cerámica. Los productos obtenidos se caracterizarán en cuanto a su nanoestructura y propiedades, en particular la piezoresistividad, porosidad, capacidad de inserción de litio y la resistencia a la oxidación.

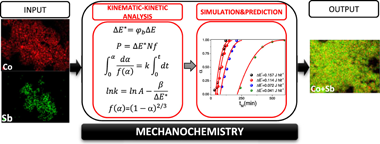

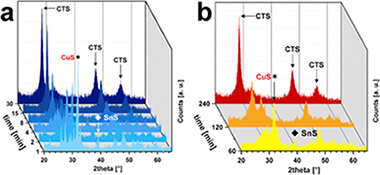

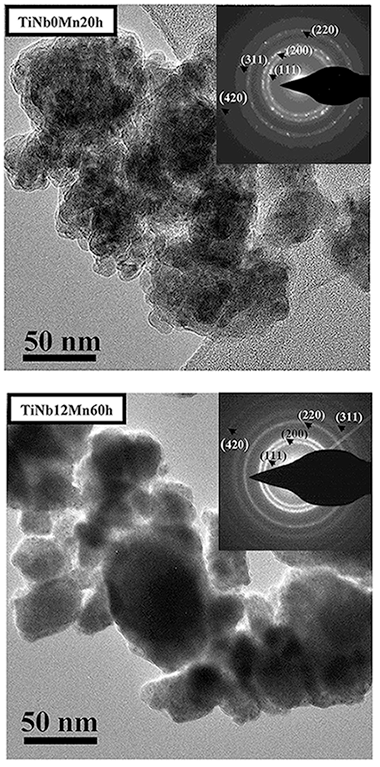

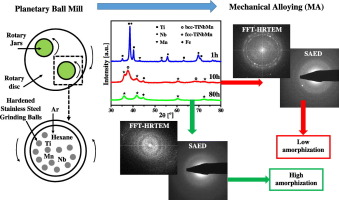

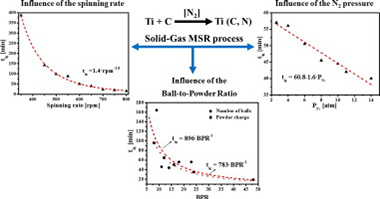

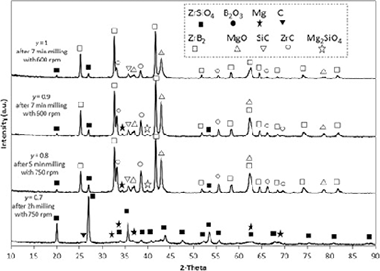

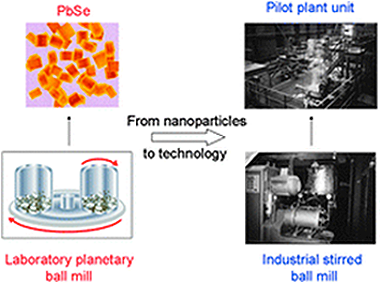

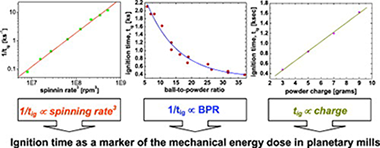

Preparación por molienda reactiva de nanocomposites de interés tecnológico

Investigador Principal: Luis A. Pérez Maqueda

Periodo: 16-05-2013 / 31-03-2018

Organismo Financiador: Junta de Andalucía

Código: P11-TEP-7858 (Proyecto de Excelencia)

Componentes: José Manuel Criado Luque, María Jesús Diánes Millán, José Luís Pérez Rodríguez, Juan Poyato Ferrera, Pedro Enrique Sánchez Jiménez, Antonio Perejón Pazo

Grupo de Investigación: Reactividad de Sólidos

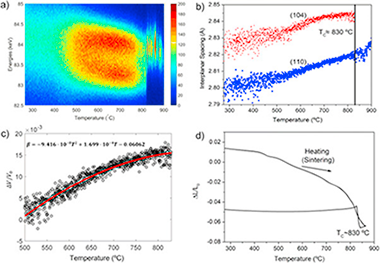

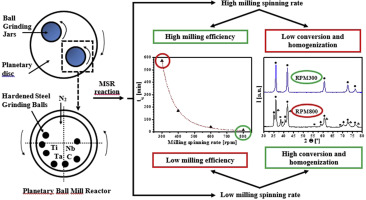

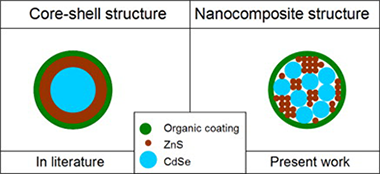

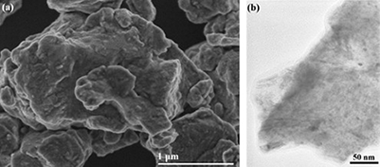

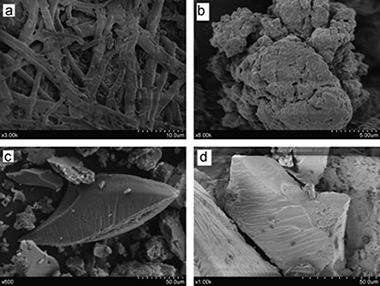

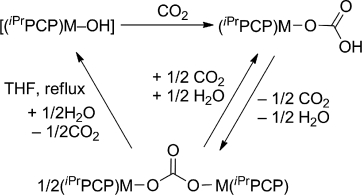

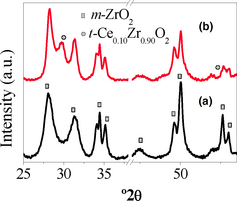

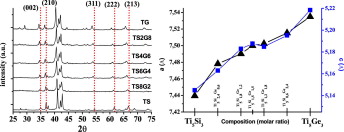

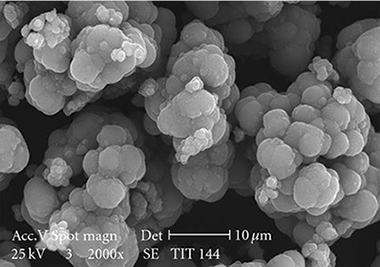

Los materiales compuestos nanométricos o nanocomposites presentan un gran interés tecnológico y académico. Estos materiales están constituidos por dos o más fases diferentes con un grado de interacción nanométrico pues una de las fases presenta al menos una dimensión menor de 100 nm. Ello les confiere unas propiedades que no se pueden conseguir con composites o materiales convencionales. En el presente proyecto se propone el uso de la molienda reactiva para obtener nanocomposites de diversa naturaleza. Esta estrategia es sostenible desde el punto de vista medioambiental a la vez que sencilla de aplicar y escalar. Para este propósito se pretende desarrollar, con la imprescindible colaboración de la empresa andaluza de ingeniería mecánica MC2, un molino planetario de alta energía con características específicas y únicas con respecto a los equipos actualmente disponibles en el mercado. Dicha empresa llevará a cabo además un estudio de las fuerzas que operan sobre la muestra en función de las variables operacionales del molino, lo que contribuirá a una mjor comprensión del mecanismo de las reacciones mecanoquímicas. Se llevará a cabo la síntesis por molienda reactiva de dos tipos de nanocomposites: a) nanocomposites de cobre reforzado tanto con inclusiones cerámicas como por precipitación a partir de aleaciones en base de cobre preparadas por aleado mecánico y b) nanocomposites tanto de zirconia parcialmente estabilizada (PSZ) como de zirconia totalmente estabilizada (TSZ) reforzada con alúmina. En este último caso, se propone para la sinterización de los polvos cerámicos, preparados por molienda reactiva, un método novedoso que implica calentar la muestra a la vez que se somete a un campo eléctrico. Con este procedimiento se espera una reducción drástica de la temperatura requerida para la compactación total de la zirconia. El estudio de la cinética de sinterización bajo los efectos de un campo eléctrico se llevará a cabo mediante un equipo a desarrollar en el proyecto a partir de un dilatómetro que se modificará de modo que permita seguir la evolución de la dimensión de la muestra en función de la temperatura estando ésta sometida a un campo eléctrico.

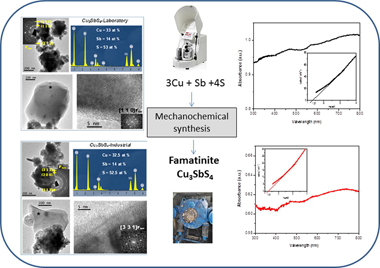

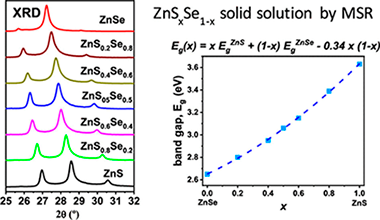

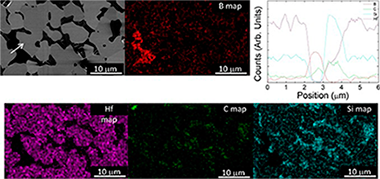

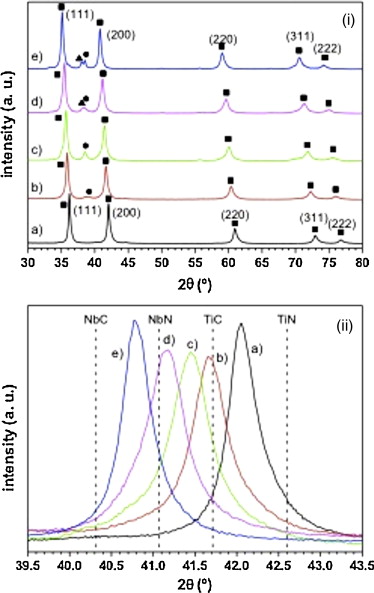

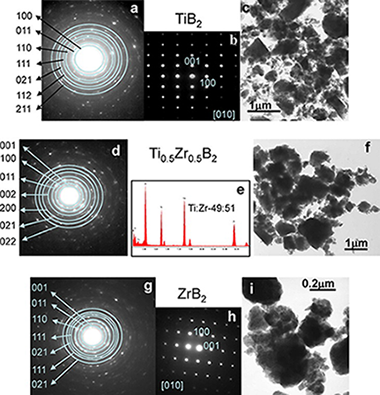

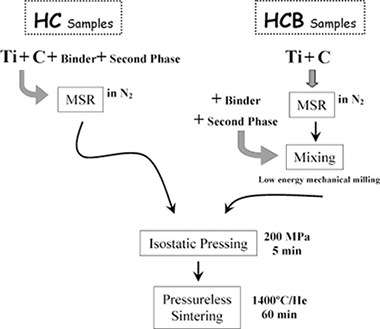

Diseño por procedimientos mecanoquímicos de materiales estructurales para aplicaciones tecnológicas de alta temperatura

Investigador Principal: Francisco José Gotor Martínez

Periodo: 01-01-2012 / 31-12-2014

Organismo Financiador: Ministerio de Ciencia e Innovación

Código: MAT2011-22981

Componentes: M. Jesús Sayagués de Vega, Concepción Real Pérez, M. Dolores Alcalá González, Pedro José Sánchez Soto, José Manuel Córdoba Gallego, Ernesto Chicardi Augusto

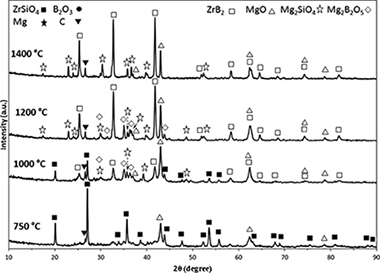

Grupo de Investigación: Reactividad de Sólidos

Los carburos, nitruros y boruros de los metales de transición son componentes esenciales de un gran número de materiales compuestos empleados para fines estructurales y de protección a altas temperaturas. Esto es debido a una excelente combinación de propiedades físicas y químicas que les confiere una buena resistencia mecánica, al desgaste, a la oxidación y a la corrosión. Los materiales basados en estos compuestos refractarios se vienen diseñando con un importante carácter multifásico, condicionado por la alta multifuncionalidad que se les exige y por la imposibilidad de alcanzar las propiedades requeridas a partir de un único compuesto.

Durante el procesado de estos materiales es frecuente observar importantes gradientes de composición e interacciones entre las distintas fases constitutivas que dificultan alcanzar las propiedades deseadas. En el presente proyecto, pretendemos abordar un nuevo diseño para este tipo de materiales consistente en incorporar la mayor parte de sus componentes esenciales como soluciones sólidas complejas. Esto permitirá reducir el número final de fases en el material y obtener con mayor garantía de éxito las propiedades preestablecidas para las diversas aplicaciones tecnológicas. Para ello, planteamos una nueva ruta de síntesis basada en el proceso mecanoquímico denominado reacción de auto-propagación inducida mecánicamente (MSR), ya que nuestro grupo ha demostrado que este método permite obtener de manera sencilla soluciones sólidas pertenecientes a los sistemas MT-B-C-N con un elevado control de la estequiometría. El objetivo principal del presente proyecto consiste en incorporar el método MSR a la metodología empleada para el desarrollo de materiales constituidos por soluciones sólidas que puedan ser utilizados en aplicaciones de alta temperatura. Se pretende caracterizar adecuadamente las propiedades de los materiales obtenidos y compararlas con aquellos fabricados con la metodología hasta ahora empleada.

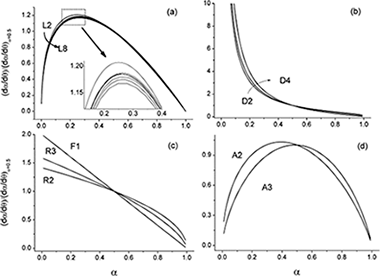

Procesado de cerámicas avanzadas a partir de precursores poliméricos (PDC) por métodos de control inteligente de la temperatura

Investigador Principal: Luis Pérez Maqueda

Periodo: 01-01-2012 / 31-12-2014

Organismo Financiador: Ministerio de Ciencia e Innovación

Código: CTQ2011-27626

Componentes: Maria Jesús Diánez Millán, José Manuel Criado Luque, Pedro E. Sánchez Jiménez, Antonio Perejón Pazo

Grupo de Investigación: Reactividad de Sólidos

Los materiales cerámicos preparados a partir de precursores poliméricos, más conocidos por las siglas PDC (polymer derived ceramics), constituyen un tema de gran interés actual. Estos materiales se preparan a partir de un polímero, que se somete a un proceso de curado previo a su descomposición térmica a temperaturas relativamente suaves si se comparan con las requeridas en un procesado cerámico convencional a partir de precursores en polvo. Este método presenta la ventaja de conducir directamente al producto final consolidado sin requerir el complejo proceso de compactación requerida por los métodos convencionales de procesado cerámico. Es por lo tanto un método "near-net shape". Estos materiales presentan propiedades eléctricas, termomecánicas y de resistencia a la oxidación muy interesantes que le confieren un amplio potencial de aplicaciones que abarcan desde la nanotecnología a la aeronáutica. Sin embargo, una limitación importante en la síntesis de estos materiales radica en la dificultad de controlar la velocidad de descomposición térmica de la pieza precerámica polimérica de modo que no se produzcan defectos, tales como fracturas, que hacen inservible el material. En este proyecto se propone el uso de los métodos de control inteligente de temperatura para el procesado de estos precursores poliméricos precerámicos. En estudios previos hemos puesto de manifiesto las ventajas de esta metodología para controlar la estructura y microestructrura de productos preparados a partir de transformaciones térmicas de precursores y para estudios cinéticos de reacciones en estado sólido. Así mediante el uso de los métodos de control inteligente de temperatura pretendemos obtener PDC libres de defectos, estudiar la influencia de las condiciones de la preparación en la nanoestructura de los productos y ahondar en el conocimiento de los procesos de conversión polímero-cerámica, con especial hincapié en el estudio de las cinéticas de los procesos involucrados. Los productos obtenidos se caracterizarán en cuanto a su nanoestructura y propiedades, en particular el coeficiente piezoeléctrico, la capacidad de inserción de litio y la resistencia a la oxidación.

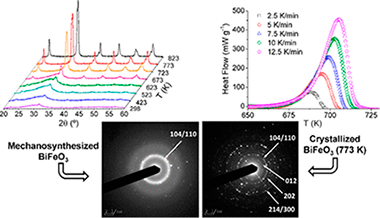

Mecanosíntesis de materiales de interés tecnológico

Investigador Principal: Francisco José Gotor Martínez

Periodo: 01-01-2011 / 31-12-2011

Organismo Financiador: Ministerio de Ciencia e Innovación

Código: MAT2010-17046

Componentes: M. Jesús Sayagués de Vega, Concepción Real Pérez, M. Dolores Alcalá González, José Manuel Córdoba Gallego, Ernesto Chicardi Augusto

Grupo de Investigación: Reactividad de Sólidos

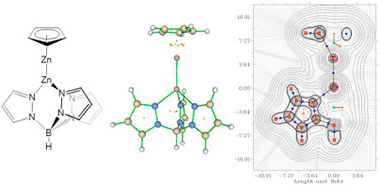

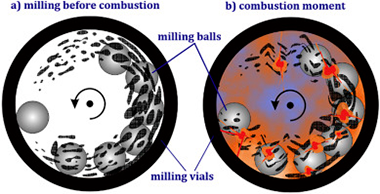

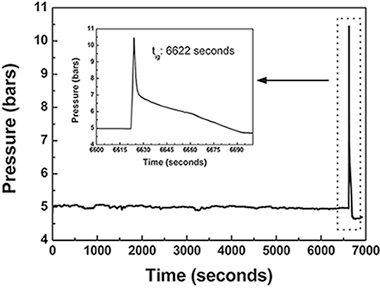

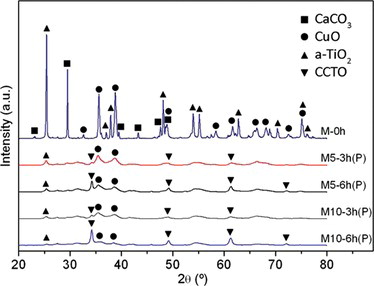

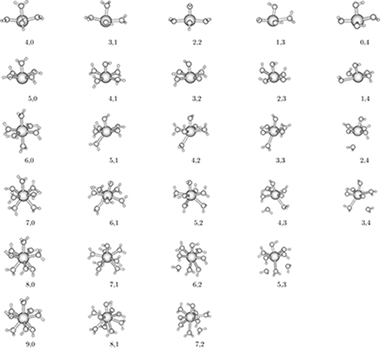

Los molinos de bolas de alta energía, planetarios, vibratorios y en menor medida los de atrición, son capaces de transferir a un sólido (ó una mezcla) cantidades importantes de energía mecánica. Los efectos de esta acción mecánica no se reducen sólo a una gradual disminución del tamaño de las partículas, sino que es posible inducir reacciones químicas en estado sólido. Como los procesos repetidos de fractura y soldadura de las partículas aumentan el área de contacto de los reactivos y se generan sin cesar superficies frescas, los procesos continuados de interdifusión hacen que la reacción ocurra a temperatura ambiente. La nueva fase formada posee, en general, un carácter nanoestructurado y presenta un gran número de defectos, lo que incide positivamente en la posterior etapa (si fuera necesaria) de sinterización. Estos procesos denominados mecanoquímicos constituyen una vía atractiva y alternativa en la síntesis de materiales nanocristalinos. Se trata de un método muy versátil que permite obtener un gran número de materiales en forma masiva, a temperatura ambiente y con un equipamiento relativamente sencillo. Este tipo de procesos es muy competitivo en término de costes y no genera ningún tipo de residuo, lo que le confiere un extraordinario valor añadido. Es un método especialmente prometedor en la obtención de soluciones sólidas complejas y de materiales compuestos tanto por su preparación con un carácter nanométrico como por la excelente homogeneidad y dispersión de los distintos constituyentes. En el presente proyecto, se pretende demostrar con ejemplos concretos que la aplicación de los procesos mecanoquímicos al campo de la síntesis de materiales permite desarrollar productos de manera más simple o que no serían posible de obtener por otros procedimientos. Los sistemas seleccionados como objeto de estudio son los siguientes: (i) carburos, nitruros y boruros de metales de transición, y (ii) óxidos mixtos con estructura perovskita de fórmula general (A1-xA’x)(B1-yB’y)O3-z (A/A’=La, Sr; B/B’=Mn, Cr, Mg, Ga). En el primer caso, se pretenden desarrollar materiales compuestos para fines estructurales basados en soluciones sólidas complejas de los compuestos refractarios especificados. En el segundo caso, se pretenden desarrollar los distintos componentes de las pilas cerámicas de combustible de forma que todos tengan la misma estructura perovskita y gran similitud composicional. Por último, indicar que se intentarán estudiar y modelizar los procesos mecanoquímicos de alta energía con el fin de realizar con mayor garantía de éxito su posible escalado.

Acoplamiento dinámica de fronteras de grano - segregación de impurezas en policristales nanoestructurados: aplicación a la circonia tetragonal dopada con itrio policristalina (YTZP)

Investigador Principal: Diego Gómez García