Scientific Papers in SCI

2020

2020

Materiales de Diseño para la Energía y Medioambiente

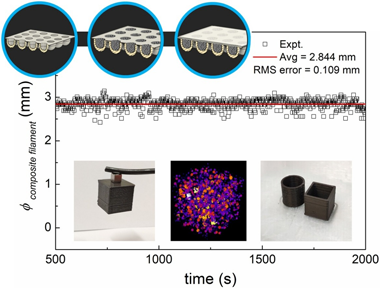

Novel procedure for laboratory scale production of composite functional filaments for additive manufacturing

Diaz-Garcia, A; Law, JY; Cota, A; Bellido-Correa, A; Ramirez-Rico, J; Schafer, R; Franco, VMaterials Today Communications, 24 (2020) 101049

Show abstract ▽

Successful 3D printing by material extrusion of functional parts for new devices requires high quality filaments. Uniform homogeneity and good dispersion of particles embedded in filaments typically takes several cycles of extrusion or well-prepared feedstock by injection molding, industrial kneaders or twin-screw compounding. These methods need specific production devices that are not available in many laboratories non-specialized in polymer research, such as those working on different material science and technology topics that try to connect with additive manufacturing. Therefore, laboratory studies are usually limited to compositions and filler concentrations provided by commercial companies. Here, we present an original laboratory scale methodology to custom-prepare the feedstock for extruding magnetic composite filaments for fused filament fabrication (FFF), which is attainable by a desktop single-screw extruder. It consists in encapsulating the fillers in custom made capsules that are used as feedstock and reach the melting area of the extruder maintaining the same concentration of fillers. Results have shown that our approach can create smooth and continuous composite filaments with good homogeneity and printability with fine level of dimensional control. We further show the good dispersion of the particles in the composite filament using X-Ray Tomography, which enabled a 3D reconstruction of the spacial distribution of the embedded magnetic particles. The major advantage of this new way of preparing the composite feedstock is that it avoids the hassle of multiple extrusion runs and industrial machinery, yet providing uniform filaments of well controlled filler concentration, which is predictable and reproducible. The proposed methodology is suitable for different polymer matrices and applicable to other functional particle types, not just limited to magnetic ones. This opens an avenue for further laboratory scale development of novel functional composite filaments, useful for any community. This democratization of complex filament preparation, including consumers preparing their own desired uniform novel filaments, will facilitate to unify efforts nearing 3D printing of new functional devices.

September, 2020 | DOI: 10.1016/j.mtcomm.2020.101049

Materiales Nanoestructurados y Microestructura

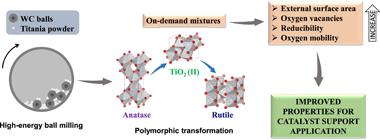

Tailoring materials by high-energy ball milling: TiO2 mixtures for catalyst support application

Rinaudo, MG; Beltran, AM; Fernandez, MA; Cadus, LE; Morales, MRMaterials Today Chemistry, 17 (2020) 100340

Show abstract ▽

We carried out a rational design of catalyst supports by high-energy ball milling. Tailored mixtures of TiO2 crystalline phases were obtained using rotational speed and milling time as variable parameters. Polymorphic transformation from anatase to rutile through high-pressure TiO2 (II) as intermediate was confirmed by X-ray Diffraction (XRD), Raman Spectroscopy and Transmission Electron Microscopy (TEM). Also, starting material doubled its specific surface area due to particle fragmentation, as confirmed by surface area of Brunauer-Emmet-Teller (S-BET) and Scanning Electron Microscopy (SEM). Defects introduced during milling process generated oxygen vacancies in the surface and bulk of supports, as evidenced by X-ray Photoelectron Spectroscopy (XPS) and Electron Paramagnetic Resonance (EPR). Furthermore, longer milling time increased reducibility and oxygen mobility of supports, as observed by H-2 Temperature Programmed Reduction (H-2-TPR) and O-2 Temperature Programmed Desorption (O-2-TPD). Phase composition remained unchanged even under extreme conditions, highlighting the stability of unusual TiO2 (II) phase. Properties achieved in present materials could benefit metal-support interactions and play a major role in supported catalysts.

September, 2020 | DOI: 10.1016/j.mtchem.2020.100340

Materiales de Diseño para la Energía y Medioambiente

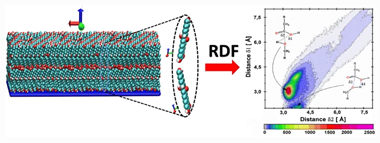

Elucidating esterification reaction during deposition of cutin monomers from classical molecular dynamics simulations

Bueno, OVM; Benitez, JJ; San-Miguel, MAJournal of Molecular Modeling, 26 (2020) 280

Show abstract ▽

The structural behavior of some cutin monomers, when deposited on mica support, was extensively investigated by our research group. However, other events, such as esterification reaction (ER), are still a way to explore. In this paper, we explore possible ER that could occur when these monomers adsorb on support. Although classical molecular dynamics simulations are not able to capture reactive effects, here, we show that they become valuable strategies to analyze the initial structural configurations to predict the most favorable reaction routes. Thus, when depositing aleuritic acid (ALE), it is observed that the loss of capacity to form self-assembled (SA) systems favors different routes to occur ER. In pure ALE bilayers systems, an ER is given exclusively through the -COOH and primary -OH groups. In pure ALE monolayers systems, the ER does not happen when the system is self-assembled. However, for disorganized systems, it is able to occur by two possible routes: -COOH and primary -OH (route 1) and -COOH and secondary -OH (route 2). When palmitic acid (PAL) is added in small quantities, ALE SAMs can now form an ER. In this case, ER occurs mostly through the -COOH and secondary -OH groups. However, when the presence of PAL is dominant, ER can occur with either of both possibilities, that is, routes 1 and 2.

September, 2020 | DOI: 10.1007/s00894-020-04544-9

Química de Superficies y Catálisis

Bimetallic PdAu catalysts for formic acid dehydrogenation

Santos, JL; Leon, C; Monnier, G; Ivanova, S; Centeno, MA; Odriozola, JAInternational Journal of Hydrogen Energy, 45 (2020) 23056-23068

Show abstract ▽

A series of monometallic and bimetallic palladium gold catalyst were prepared and studied for the formic acid dehydrogenation reaction. Different Pd/Au compositions were employed (PdxAu100-x, where x = 25; 50 and 75) and their impact on alloy structure, particle size and dispersion was evaluated. Active phase composition and reaction parameters such as temperature, formic acid concentration or formate/formic acid ratio were adjusted to obtain active and selective catalyst for hydrogen production. An important particle size effect was observed and related to Pd/Au composition for all bimetallic catalysts.

September, 2020 | DOI: 10.1016/j.ijhydene.2020.06.076

Química de Superficies y Catálisis

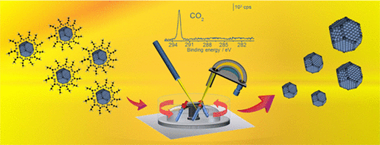

Free-Carbon Surface for PtCu Nanoparticles: An In Situ Near Ambient Pressure X-ray Photoelectron Spectroscopy Study

Castillo, R; Navarro-Jaen, S; Romero-Sarria, F; Perez-Dieste, V; Escudero, C; Centeno, MA; Daturi, M; Odriozola, JAJournal of Physical Chemistry C, 124 (2020) 19046-19056

Show abstract ▽

Usually, nanoparticle synthesis methodologies require the use of organic molecules (capping agent, solvent molecules, etc.), which results in carbon deposits on the nanoparticle surface. These residues modify the surface properties mainly affecting the catalytic behavior. In this work, unsupported poly(vinylpyrrolidone) (PVP)-stabilized PtCu (1:3 molar ratio) bimetallic alloy nanoparticles were synthetized and characterized. An alternative surface cleaning method has been designed, which successfully removes the presence of organic fragments. To address this key issue, we have combined a first nanoparticle washing step with a near ambient pressure X-ray photoelectron spectroscopy (NAPXPS) study in order to obtain a clean active site and the total understanding of the carbon elimination mechanism. The dynamic evolution of the surface organic species composition under different gas mixtures at 750 mTorr and 350 degrees C has been studied, and only under CO2 exposure, NAPXPS analysis revealed a total availability of the active site by the removal of the organic nanoparticle coating.

September, 2020 | DOI: 10.1021/acs.jpcc.0c04713

- ‹ previous

- 94 of 410

- next ›