Scientific Papers in SCI

2022

2022

Reactividad de Sólidos

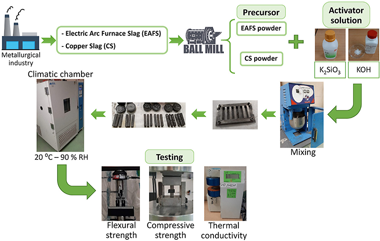

Comparative study of alkali activated cements based on metallurgical slags, in terms of technological properties developed

Gomez-Casero, MA; Perez-Villarejo, L; Sanchez-Soto, PJ; Eliche-Quesada, DSustainable Chemistry and Pharmacy, 29 (2022) 100746 DOI: 10.1016/j.scp.2022.100746

Abstract

In this work, an investigation on the use of two slags from different origins (electric arc furnace slag (EAFS) and copper slag (CS)) as raw materials in the manufacture of alkali-activated cements has been carried out. A comparison of the different mechanical properties developed by the alkaline activation of each raw material has been studied. Combination of 35 wt% potassium hydroxide (KOH) solution with different concentration (5, 8, 12 and 15 M) and 65 wt% potassium silicate (K2SiO3) solution was used as activating solution to manufacture alkali activated cements. The pastes were cured 24 h in a climatic chamber at 20 ºC at 90% of relative humidity, subsequently demoulded and cured at same condition during 1, 7, 28 and 90 days. Alkali activated materials have been characterized using Fourier transform infrared spectroscopy (FTIR), X-ray diffraction (XRD) and scanning electron microscopy (SEM). The physical properties: bulk density, water absorption and apparent porosity, mechanical properties, flexural strength and compressive strength and thermal properties: thermal conductivity have been determined. The results indicate that two types of slags studied are a suitable source of aluminosilicates that can be activated for the manufacture of alkali-activated materials. These precursors are capable of developing high values of flexural and compressive strength and low values of thermal conductivity when optimal concentration of KOH was used. The optimal composition was developed when CS was utilized. Binders with CS and 12 M M ratio achieved compressive strength values up to 70 MPa.

October, 2022 · DOI: 10.1016/j.scp.2022.100746

Nanotecnología en Superficies y Plasma

Design and Characterization of ITO-Covered Resonant Nanopillars for Dual Optical and Electrochemical Sensing

Tramarin, L; Casquel, R; Gil-Rostra, J; Gonzalez-Martinez, MA; Herrero-Labrador, R; Murillo, AMM; Laguna, MF; Banuls, MJ; Gonzalez-Elipe, AR; Holgado, MChemosensors, 10 (2022) 393 DOI: 10.3390/chemosensors10100393

Abstract

In this work we present a dual optical and electrochemical sensor based on SiO2/Si3N4 resonant nanopillars covered with an indium tin oxide (ITO) thin film. A 25-30 nm thick ITO layer deposited by magnetron sputtering acts as an electrode when incorporated onto the nanostructured array, without compromising the optical sensing capability of the nanopillars. Bulk sensing performances before and after ITO deposition have been measured and compared in accordance with theoretical calculations. The electrochemical activity has been determined by the ferri/ferrocyanide redox reaction, showing a remarkably higher activity than that of flat thin films of similar ITO nominal thickness, and proving that the nanopillar system covered by ITO presents electrical continuity. A label-free optical biological detection has been performed, where the presence of amyloid-beta has been detected through an immunoassay enhanced with gold nanoparticles. Again, the experimental results have been corroborated by theoretical simulations. We have demonstrated that ITO can be a beneficial component for resonant nanopillars sensors by adding potential electrochemical sensing capabilities, without significantly altering their optical properties. We foresee that resonant nanopillars coated with a continuous ITO film could be used for simultaneous optical and electrochemical biosensing, improving the robustness of biomolecular identification.

October, 2022 · DOI: 10.3390/chemosensors10100393

Materiales Ópticos Multifuncionales

Enhanced red-UC luminescence through Ce3+ co-doping in NaBiF4:Yb3+/Ho3+(Er3+)/Ce3+ phosphors prepared by ultrafast coprecipitation approach

Giordano, L; Du, H; Castaing, V; Luan, F; Guo, D; Viana, BOptical Materials X, 16 (2022) 100199 DOI: 10.1016/j.omx.2022.100199

Abstract

Series of Yb3+/Ho3+(Er3+)/Ce3+ co-doped NaBiF4 phosphors were synthesized through an ultrafast co-precipitation reaction technique at room temperature. The effect of the Ce3+ ions on the crystal structure and upconversion (UC) luminescence properties of the studied samples were investigated in detail. FTIR and XPS demonstrated the pre-formation of NaBiF4 and the introduction of Yb3+, Ho3+, Er3+ and Ce3+ all as dopants in the host materials. Under 980 nm excitation, NaBiF4:Yb3+,Ho3+(Er3+),Ce3+performed the characteristic emission of the activator ion, and the introduction of Ce3+ did not change the emission wavelengths, only the relative intensities. Due to partial good energy overlap when 2F7/2 Ce3+ manifold is populated, raising Ce3+ ions concentration enhanced the red UC emission versus green UC emission but also lead to significant decrease in the average lifetimes of all monitored emissions for Ho3+ and Er3+. These lifetime decreases are explained by the energy loss in non-radiative pathways after the introduction of Ce3+. In addition, the green to yellow color emission change through addition of Ce3+ was explored in NaBiF4: Yb3+,Ho3+,Ce3+ to propose a novel application in two-level anti-counterfeiting.

October, 2022 · DOI: 10.1016/j.omx.2022.100199

Nanotecnología en Superficies y Plasma

Multiscale Kinetic Monte Carlo Simulation of Self-Organized Growth of GaN/AlN Quantum Dots

Budagosky, JA; García-Cristobal, ANanomaterials, 12 (2022) 3052 DOI: 10.3390/nano12173052

Abstract

A three-dimensional kinetic Monte Carlo methodology is developed to study the strained epitaxial growth of wurtzite GaN/AlN quantum dots. It describes the kinetics of effective GaN adatoms on an hexagonal lattice. The elastic strain energy is evaluated by a purposely devised procedure: first, we take advantage of the fact that the deformation in a lattice-mismatched heterostructure is equivalent to that obtained by assuming that one of the regions of the system is subjected to a properly chosen uniform stress (Eshelby inclusion concept), and then the strain is obtained by applying the Green's function method. The standard Monte Carlo method has been modified to implement a multiscale algorithm that allows the isolated adatoms to perform long diffusion jumps. With these state-of-the art modifications, it is possible to perform efficiently simulations over large areas and long elapsed times. We have taylored the model to the conditions of molecular beam epitaxy under N-rich conditions. The corresponding simulations reproduce the different stages of the Stranski-Krastanov transition, showing quantitative agreement with the experimental findings concerning the critical deposition, and island size and density. The influence of growth parameters, such as the relative fluxes of Ga and N and the substrate temperature, is also studied and found to be consistent with the experimental observations. In addition, the growth of stacked layers of quantum dots is also simulated and the conditions for their vertical alignment and homogenization are illustrated. In summary, the developed methodology allows one to reproduce the main features of the self-organized quantum dot growth and to understand the microscopic mechanisms at play.

September, 2022 · DOI: 10.3390/nano12173052

Nanotecnología en Superficies y Plasma

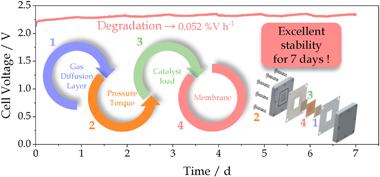

Optimization of anion exchange membrane water electrolyzers using ionomer-free electrodes

Lopez-Fernandez, E; Gomez-Sacedon, C; Gil-Rostra, J; Espinos, JP; Brey, JJ; Gonzalez-Elipe, AR; de Lucas-Consuegra, A.; Yubero, FRenewable Energy, 197 (2022) 1183-1191 DOI: 10.1016/j.renene.2022.08.013

Abstract

This work is carried out in the context of the anion exchange membrane water electrolysis (AEMWE) and pursuits to determine the influence of different cell components on the global electrochemical performance. Ionomer-free electrodes consisting of anodic Ni-Fe and cathodic Ni electrocatalysts deposited by magnetron sputtering in an oblique angle deposition configuration were utilized for this study. In addition to the characteristics and equivalent thickness of the electrocatalysts, other factors affecting the efficiency that have been considered in this study encompass the type of gas diffusion layer (GDLs), including carbon paper and stainless-steel fiber paper supports, and several commercial anion exchange membranes. The electrocatalytic performances in both a threeelectrode and complete single cell AEMWE set-ups, together with the physico-chemical characterization of the electrodes before and after operation, have served to select the optimum components for the utilized cell configuration. Thus, current densities of 670 mA cm-2, at polarization voltage of 2.2 V, 1.0 M KOH electrolyte and 40 degrees C were obtained in a membrane electrode assembly. A seven days chronopotentiometry experiment at a fixed current of 400 mA cm-2 demonstrated a noticeable stability of this type of AEMWE cells incorporating ionomer-free electrodes.

September, 2022 · DOI: 10.1016/j.renene.2022.08.013

Reactividad de Sólidos

Oxygen production routes assessment for oxy-fuel combustion

Garcia-Luna, S; Ortiz, C; Carro, A; Chacartegui, R; Perez-Maqueda, LAEnergy, 254 (2022) 124303 DOI: 10.1016/j.energy.2022.124303

Abstract

Oxyfuel combustion is a promising alternative to decarbonize the power sector. However, the main barrier to commercial deployment of the technology is the high energy consumption associated with oxygen production (-200-300 kWh per ton of O-2), which penalizes the thermal-to-electric efficiency of 8.5-12% compared to traditional air combustion plants. Typically, oxygen is obtained from a cryogenic air separation process. However, other technologies have been gaining momentum in recent years, such as membrane technologies, chemical looping air separation, and renewable-driven electrolysis. The present work evaluates all these options for O-2 production to retrofit a 550 MWe coal-fired power plant with oxyfuel combustion. A techno-economic assessment is carried out to estimate the energy penalty, the O-2 production cost (V/ton) and the Levelized Cost of Electricity. The best results are obtained by combining oxygen transport membranes and electrolysis since the energy consumption has been reduced to 98.56 kWh/ton of O(2, )decreasing by 59.31% the cryogenic distillation energy consumption (242.24 kWh/ ton O2), reducing the overall energy penalty compared to cryogenic air separation from 8.88% points to 7.56%points. The oxygen transport membrane presents the lowest cost of electricity in retrofitting cases, 51.48 $/MWh, while cryogenic distillation estimated cost is 52.7 $/MWh. Their costs of avoided CO2 are 31.79 $/ton CO2 and 34.15 $/ton CO2 respectively.

September, 2022 · DOI: 10.1016/j.energy.2022.124303

Química de Superficies y Catálisis

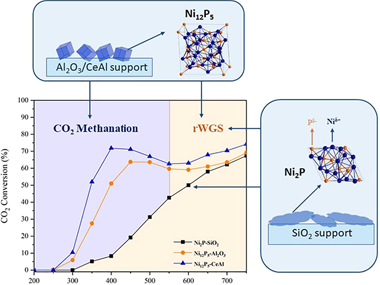

Ni-Phosphide catalysts as versatile systems for gas-phase CO2 conversion: Impact of the support and evidences of structure-sensitivity

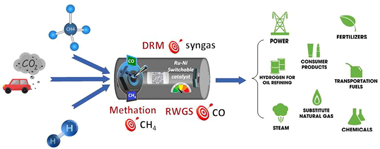

Zhang, Q; Pastor-Perez, L; Villora-Pico, JJ; Joyce, M; Sepulveda-Escribano, A; Duyar, MS; Reina, TRFuel, 323 (2022) 124301 DOI: 10.1016/j.fuel.2022.124301

Abstract

We report for the first time the support dependent activity and selectivity of Ni-rich nickel phosphide catalysts for CO2 hydrogenation. New catalysts for CO2 hydrogenation are needed to commercialise the reverse water-gas shift reaction (RWGS) which can feed captured carbon as feedstock for traditionally fossil fuel-based processes, as well as to develop flexible power-to-gas schemes that can synthesise chemicals on demand using surplus renewable energy and captured CO2. Here we show that Ni2P/SiO2 is a highly selective catalyst for RWGS, producing over 80% CO in the full temperature range of 350-750 degrees C. This indicates a high degree of suppression of the methanation reaction by phosphide formation, as Ni catalysts are known for their high methanation activity. This is shown to not simply be a site blocking effect, but to arise from the formation of a new more active site for RWGS. When supported on Al2O3 or CeAl, the dominant phase of as synthesized catalysts is Ni12P5. These Ni12P5 catalysts behave very differently compared to Ni2P/SiO2, and show activity for methanation at low temperatures with a switchover to RWGS at higher temperatures (reaching or approaching thermodynamic equilibrium behaviour). This switchable activity is interesting for applications where flexibility in distributed chemicals production from captured CO2 can be desirable. Both Ni12P5/Al2O3 and Ni12P5/CeAl show excellent stability over 100 h on stream, where they switch between methanation and RWGS reactions at 50-70% conversion. Catalysts are characterized before and after reactions via X-ray Diffraction (XRD), X-ray Photoelectron Spectroscopy (XPS), temperature-programmed reduction and oxidation (TPR, TPO), Transmission Electron Microscopy (TEM), and BET surface area measurement. After reaction, Ni2P/SiO(2 )shows the emergence of a crystalline Ni12P5 phase while Ni12P5/Al2O3 and Ni12P5/CeAl both show the crystalline Ni3P phase. While stable activity of the latter catalysts is demonstrated via extended testing, this Ni enrichment in all phosphide catalysts shows the dynamic nature of the catalysts during operation. Moreover, it demonstrates that both the support and the phosphide phase play a key role in determining selectivity towards CO or CH4.

September, 2022 · DOI: 10.1016/j.fuel.2022.124301

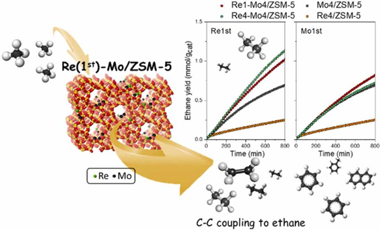

Materiales y Procesos Catalíticos de Interés Ambiental y Energético

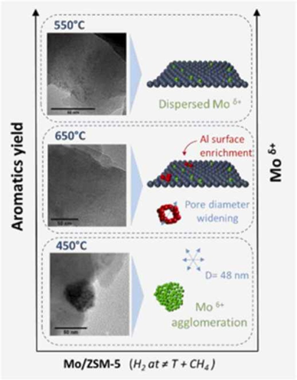

Unraveling the Mo/HZSM-5 reduction pre-treatment effect on methane dehydroaromatization reaction

Lopez-Martin, A; Caballero, A; Colon, GApplied Catalysis B-Environmental, 312 (2022) 121382 DOI: 10.1016/j.apcatb.2022.121382

Abstract

Reduction pre-treatment at different temperatures were performed over Mo/HZSM-5 system before methane dehydroaromatiztion reaction. We have shown the crucial effect of reduction temperature on the final catalytic performance. Outstanding improvement in the aromatics conversion has been attained. Thus, H-2 formation form methane cracking reaction seems to be hindered for pre-treated catalysts. As a consequence, the deposition of coke in these samples appeared also notably suppressed. The optimum performance has been achieved for reduction pre-treatment at 550 degrees C. For this temperature, we have observed that the fraction of reduced Mo species is higher.

September, 2022 · DOI: 10.1016/j.apcatb.2022.121382

Química de Superficies y Catálisis

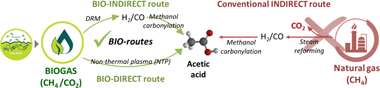

Sustainable routes for acetic acid production: Traditional processes vs a low-carbon, biogas-based strategy

Martin-Espejo, JL; Gandara-Loe, J; Odriozola, JA; Reima, TR; Pastor-Pérez, LScience of the Total Environment, 840 (2022) 156663 DOI: 10.1016/j.scitotenv.2022.156663

Abstract

The conversion of biogas, mainly formed of CO2 and CH4, into high-value platform chemicals is increasing attention in a context of low-carbon societies. In this new paradigm, acetic acid (AA) is deemed as an interesting product for the chemical industry. Herein we present a fresh overview of the current manufacturing approaches, compared to potential low-carbon alternatives. The use of biogas as primary feedstock to produce acetic acid is an auspicious alternative, representing a step-ahead on carbon-neutral industrial processes. Within the spirit of a circular economy, we propose and analyse a new BIO-strategy with two noteworthy pathways to potentially lower the environmental impact. The generation of syngas via dry reforming (DRM) combined with CO2 utilisation offers a way to produce acetic acid in a two-step approach (BIO-Indirect route), replacing the conventional, petroleum-derived steam reforming process. The most recent advances on catalyst design and technology are discussed. On the other hand, the BIO-Direct route offers a ground-breaking, atom-efficient way to directly generate acetic acid from biogas. Nevertheless, due to thermodynamic restrictions, the use of plasma technology is needed to directly produce acetic acid. This very promising approach is still in an early stage. Particularly, progress in catalyst design is mandatory to enable low-carbon routes for acetic acid production.

September, 2022 · DOI: 10.1016/j.scitotenv.2022.156663

Materiales Avanzados

Pre-Roman and Republican amphorae (III-I centuries b.C.) from production contexts of the Guadalquivir Basin: technical and compositional characterization

Moreno-Megías, V.; García-Fernández, F.J.; Martín-del-Río, J.J.; Borreguero-Cid, M.; Sánchez-Soto, P.J.Boletín de la Sociedad Española de Cerámica y Vidrio, 61 (2022) 498-515 DOI: 10.1016/j.bsecv.2021.03.008

Abstract

The present work consists of an archaeometric investigation concerning ceramic samples, mostly unpublished, of the III-I centuries b.C. They were found in connection with kilns of the city of Sevilla (Archbishop's Palace) and the countryside (Arrabal zone, Carmona). They are identified with evolved variations of Iron Age amphorae of Punic and Turdetanian tradition, or already Roman typologies. The main objectives of this research include their technological and compositional characterization as well as the comparison of the characteristics of each manufacture tradition.

An assemblage of 13 samples has been studied through petrographic analysis of thin sections, chemical analysis (X-ray fluorescence) and mineralogical analysis (X-ray diffraction). The chemical results showed the silico-aluminous and calcitic character of the samples, with variable contents of iron oxide as well as other minor elements and traces. The statistical treatment of the data by multivariant analysis has differentiated 3 conglomerates and one sample as an outsider. The mineralogical analysis has identified 8 crystalline phases, several of them already present in the raw materials and others formed by thermal treatment. It is interesting to note the illite, identified as dehydroxylated phase, anorthite, diopside and gehlenite. The petrographical analysis has identified 3 different petro-groups, which are correlated by a compositional point of view with the original context of the samples. Thus, according to these results, it has been possible to distinguish the manufactures of Sevilla from the Roman shapes, the common ware and the imitation types of Carmona.

It has been discussed the possible solid-state reactions which yielded the crystalline phases identified by X-ray diffraction, besides an estimation of firing temperatures between 820-850 degrees C in an oxidant atmosphere. Finally, the possible sources for the raw materials used in the fabrication of these amphorae have been proposed in the Guadalquivir River valley, considering their illitic-calcitic characteristics.

September, 2022 · DOI: 10.1016/j.bsecv.2021.03.008

Química de Superficies y Catálisis

Hydrogen production from landfill biogas: Profitability analysis of a real case study

Vidal-Barrero, F; Baena-Moreno, FM; Preciado-Cardenas, C; Villanueva-Perales, A; Reina, TRFuel, 324 (2022) 124438 DOI: 10.1016/j.fuel.2022.124438

Abstract

Hydrogen is not only considered as a cornerstone within renewable energy portfolio but it is also a key enabler for CO2 valorisation being a central resource for industrial decarbonization. This work evaluates the profitability of hydrogen production via combined biogas reforming and water-gas shift reaction, based on a real case scenario for landfill biogas plant in Seville (Spain). A techno-economic model was developed based on a process model and the discounted cash-flow method. A biogas flow of 700 m(3)/h (input given by the landfill biogas plant) was used as plant size and the analysis was carried out for two different cases: (1) use of already available energy sources at the industrial plant, and (2) solar energy generation to power the process. The economic outputs obtained showed that under the current circumstances, this hydrogen production route is not profitable. The main reason is the relatively low current hydrogen prices which comes from fossil fuels. A revenues analysis indicates that hydrogen from biogas selling prices between 2.9 and 5.7 euro/kg would be needed to reach profitability, which are considerably higher than the current hydrogen cost (1.7 euro/kg). A subsidy scheme is suggested to improve the competitiveness of this hydrogen production process in the short-medium term. A cost analysis is also performed, revealing that electricity prices and investment costs have a high impact on the total share (23-40% and 8-22%, respectively). Other potential costs reduction such as catalyst, labour and manteinance & overhead are also evaluated, showing that cutting-down production costs is mandatory to unlock the potential of hydrogen generation from biogas. Our work showcases the techno-economic challenge that green energy policies face in the path toward sustainable societies.

September, 2022 · DOI: 10.1016/j.fuel.2022.124438

Materiales para Bioingeniería y Regeneración Tisular

Sol-Gel Synthesis of Endodontic Cements: Post-Synthesis Treatment to Improve Setting Performance and Bioactivity

Song, X; Diaz-Cuenca, AMaterials, 15 (2022) 6051 DOI: 10.3390/ma15176051

Abstract

The sol-gel process is a wet chemical technique that allows very fine control of the composition, microstructure, and final textural properties of materials, and has great potential for the synthesis of endodontic cements with improved properties. In this work, the influence of different sol-gel synthesis variables on the preparation of endodontic cement based on calcium silicate with Ca/Si stoichiometry equal to 3 was studied. Starting from the most optimal hydraulic composition selected, a novel second post-synthesis treatment using ethanol was essayed. The effects of the tested variables were analyzed by X-ray diffraction, infrared spectroscopy, scanning electron microscopy, nitrogen physisorption, and Gillmore needles to determine the setting time and simulated body fluid (SBF) immersion to measure the bioactive response in vitro. The results indicated that the sol-gel technique is effective in obtaining bioactive endodontic cements (BECs) with high content of the hydraulic compound tricalcium silicate (C3S) in its triclinic polymorph. The implementation of a novel post-synthesis treatment at room temperature using ethanol allows obtaining a final BEC product with a finer particle size and a higher CaCO3 content, which results in an improved material in terms of setting time and bioactive response.

September, 2022 · DOI: 10.3390/ma15176051

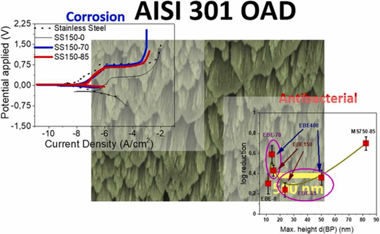

Tribología y Protección de Superficies

Influence of the carbon incorporation on the mechanical properties of TiB2 thin films prepared by HiPIMS

Sala, N; Abad, MD; Sanchez-Lopez, JC; Crugeira, F; Ramos-Masana, A; Colominas, CInternational Journal of Refractory Metals & Hard Materials, 107 (2022) 105884 DOI: 10.1016/j.ijrmhm.2022.105884

Abstract

Nanostructured TiB2 and TiBC thin films with carbon contents up to 11 at. % were prepared by physical vapor deposition using high power impulse magnetron sputtering (HiPIMS) technology. The influence of carbon incorporation during the deposition of TiB2 coatings was investigated on the chemical composition, microstructure and mechanical properties by means of scanning electron microscopy, atomic force microscopy, x-ray photoelectron spectroscopy (XPS), x-ray diffraction (XRD), nanoindentation, scratch test, calotest and adhesion Daimler-Benz test. The results indicated that small additions of carbon up to 3 at. % improved the mechanical behavior and increased the adhesion of the TiB2 thin films. Hardnesses up to 37 GPa were reached and the adhesion of the coating to AISI D2 steel substrates increased from 11 to 18 N. XRD and XPS results showed that the carbon atoms are either occupying interstitial sites within the hexagonal structure of the TiB2 or forming bonds with titanium and boron atoms. The preferred orientation of the films determined by XRD also changed with the increasing carbon content in the (001) crystalline plane.

September, 2022 · DOI: 10.1016/j.ijrmhm.2022.105884

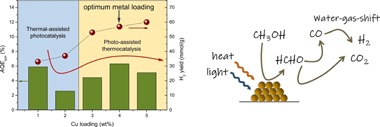

Materiales y Procesos Catalíticos de Interés Ambiental y Energético

Tuning the co-catalyst loading for the optimization of thermo-photocatalytic hydrogen production over Cu/TiO2

Platero, F; Caballero, A; Colon, GApplied Catalysis A-General, 643 (2022) 118804 DOI: 10.1016/j.apcata.2022.118804

Abstract

We have optimized the H-2 production by methanol thermo-photocatalytic reforming in the gas phase using Cu/TiO2 catalyst by tuning metal loading. Metal co-catalyst has been deposited by means of chemical reduction deposition. We have stated that thermo- and thermo-photocatalytic process leads to a notable H-2 production at 200 C. By in-situ FTIR studies we evidenced that formate formation follows a different evolution depending on the reforming experiment. These surface formate would lead to CO formation through dehydration reaction. At higher Cu content the low CO selectivity denote that water-gas-shift reaction would predominate and exalt H-2 yield. Thus, different optimum Cu content is found for each reforming experiment. While for the photocatalytic reforming Cu/TiO2 (2 wt%) is the best catalyst of the series, we should increase the Cu content to Cu/TiO2 (5 wt%) to achieve the optimum performance for thermo-photocatalytic reforming of methanol.

August, 2022 · DOI: 10.1016/j.apcata.2022.118804

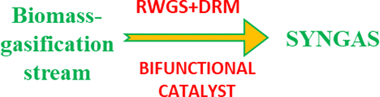

Química de Superficies y Catálisis

Catalytic Upgrading of Biomass-Gasification Mixtures Using Ni-Fe/ MgAl2O4 as a Bifunctional Catalyst

Tarifa, P; Reina, TR; González-Castaño, M; Arellano-Garcia, HEnergy & Fuels, 36 (2022) 8267-8273 DOI: 10.1021/acs.energyfuels.2c01452

Abstract

Biomass gasification streams typically contain a mixture of CO, H-2, CH4, and CO(2 )as the majority components and frequently require conditioning for downstream processes. Herein, we investigate the catalytic upgrading of surrogate biomass gasifiers through the generation of syngas. Seeking a bifunctional system capable of converting CO2 and CH4 to CO, a reverse water gas shift (RWGS) catalyst based on Fe/MgAl(2)O(4 )was decorated with an increasing content of Ni metal and evaluated for producing syngas using different feedstock compositions. This approach proved efficient for gas upgrading, and the incorporation of adequate Ni content increased the CO content by promoting the RWGS and dry reforming of methane (DRM) reactions. The larger CO productivity attained at high temperatures was intimately associated with the generation of FeNi3 alloys. Among the catalysts' series, Ni-rich catalysts favored the CO productivity in the presence of CH4, but important carbon deposition processes were noticed. On the contrary, 2Ni-Fe/MgAl2O4 resulted in a competitive and cost-effective system delivering large amounts of CO with almost no coke deposits. Overall, the incorporation of a suitable realistic application for valorization of variable composition of biomass-gasification derived mixtures obtaining a syngas-rich stream thus opens new routes for biosyngas production and upgrading.

August, 2022 · DOI: 10.1021/acs.energyfuels.2c01452

Reactividad de Sólidos

Low-pressure calcination to enhance the calcium looping process for thermochemical energy storage

Ortiz, C; Carro, A; Chacartegui, R; Valverde, JM; Perejon, A; Sánchez-Jiménez, PE; Pérez-Maqueda, LAJournal of Cleaner Production, 363 (2022) 132295 DOI: 10.1016/j.jclepro.2022.132295

Abstract

The Calcium-Looping (CaL) process, based on the multicyclic calcination-carbonation of CaCO3/CaO, is considered a promising Thermochemical Energy Storage (TCES) technology to be integrated into Concentrating Solar Power (CSP) plants. This work proposes a novel CaL integration that operates at low-pressure calcination under pure CO2 and a moderated temperature. Low-pressure calcination (0.01 bar) provides a suitable solution to mitigate CaO sintering and its consequent loss of reactivity in the carbonation stage. Since the temperature for quick calcination in a pure CO2 atmosphere is decreased (from around 950 °C at 1 bar to 765 °C at 0.01 bar), the energy losses at the receiver are minimised. In addition, a reduced calcination temperature allows for the use of metallic receivers already tested at the MW-scale, which significantly increases the CSP-CaL integration reliability. Moreover, multicycle CaO reactivity is promoted in short residence times, allowing the use of a simpler reactor design. Furthermore, there is an increase of 85% in the energy storage density of the system. The proposed plant proposes a smooth integration of the CaL process in CSP plants, with a moderate storage level and supported by a natural gas backup system (solar share higher than 50%). The results show that the solar thermal-to electric efficiency is above 30%.

August, 2022 · DOI: 10.1016/j.jclepro.2022.132295

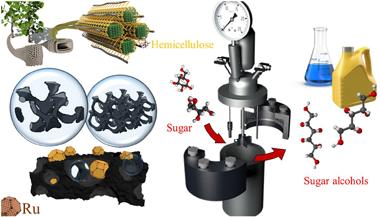

Química de Superficies y Catálisis

Structure effect of modified biochar in Ru/C catalysts for sugar mixture hydrogenation

Santos, JL; Sanz-Moral, LM; Aho, A; Ivanova, S; Murzin, DY; Centeno, MABiomass & Bioenergy, 163 (2022) 106504 DOI: 10.1016/j.biombioe.2022.106504

Abstract

This study deals with the production and activation of biochars and their use as supports for a series of ruthenium catalysts for hydrogenation of L-arabinose/D-galactose sugar mixture. The synthesized biochars differ in physicochemical properties and surface chemistry influencing ruthenium metal uptake and dispersion and as a consequence its catalytic behaviour. Selectivity exceeding 95% was observed for both hexitols. The catalytic performance of the prepared Ru supported catalysts is also compared to the already known Ru/activated carbon commercial catalyst.

August, 2022 · DOI: 10.1016/j.biombioe.2022.106504

Química de Superficies y Catálisis

Recent advances on gas-phase CO2 conversion: Catalysis design and chemical processes to close the carbon cycle

Torres-Sempere, G; Pastor-Perez, L; Odriozola, JA; Yu, J; Duran-Olivencia, FJ; Bobadilla, LF; Reina, TRCurrent Opinion in Green andd Sustainable Chemistry, 36 (2022) 100647 DOI: 10.1016/j.cogsc.2022.100647

Abstract

Chemical CO2 recycling in the gas phase constitutes a straightforward approach for effective CO2 conversion to added-value products like syngas or synthetic methane. In this scenario, some traditional processes such as the dry and bi-reforming of methane, the CO2 methanation and the reverse water-gas shift have gained a renewed interest from the CO2 utilisation perspective. Indeed, these reactions represent flexible routes to upgrade CO2 and their application at an industrial scale could substantially reduce CO2 emissions. The bottleneck for the implementation of these processes at the commercial level is the development of highly active and robust heterogeneous catalysts able to overcome CO2 activation and deliver sufficient amounts of the upgrading products (i.e. syngas or synthetic natural gas) at the desired operating conditions. This review paper gathers the most recent advances in the design of new catalytic formulations for chemical CO2 recycling in the gas phase and constitutes an overview for experts and newcomers in the field to get fundamental insights into this emerging branch of low-carbon technologies.

August, 2022 · DOI: 10.1016/j.cogsc.2022.100647

Reactividad de Sólidos

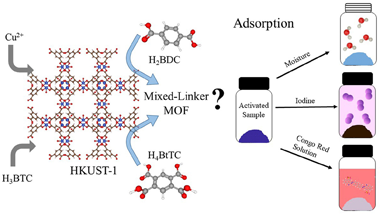

On the adsorption properties and applications of mixed-linker MOFs based on HKUST-1

Puerto-Rodríguez, M; López-Cartes, C; Ayala, RJournal of Solid State Chemistry, 312 (2022) 123260 DOI: 10.1016/j.jssc.2022.123260

Abstract

Different mixed-linker MOFs based on HKUST-1 have been successfully synthesized using BtTC (1,2,4,5-benzenetetracarboxylate) and BDC (1,4-benzenedicarboxylate) as modulator ligands. These MOFs maintain the HKUST-1 structure up to 25% and 50% of trimesic acid replacing with BtTC and BDC ligands, respectively. A low percentage of modulator ligand provokes an increasing of the MOF surface area keeping its microporosity whereas a higher content of BtTC induces mesoposority in the samples. The adsorption of moisture ambient or vapour iodine reveals that there is a relation between the surface area and the capacity of adsorption of the samples. However, this relation is not found in the experiments of Congo Red removal from aqueous and ethanol solutions. The pH of the solutions has a significant effect on the adsorption capacity of the samples.

August, 2022 · DOI: 10.1016/j.jssc.2022.123260

Nanotecnología en Superficies y Plasma

One-Dimensional Photonic Crystal for Surface Mode Polarization Control

Mogni, E; Pellegrini, G; Gil-Rostra, J; Yubero, F; Simone, G; Fossati, S; Dostalek, J; Vazquez, RM; Osellame, R; Celebrano, M; Finazzi, M; Biagioni, PAdvanced Optical Materials, (2022) 2200759 DOI: 10.1002/adom.202200759

Abstract

Bloch surface waves sustained by truncated 1D photonic crystals (1DPCs) are well known tools for surface-enhanced spectroscopy. They provide strongly confined fields with uniform distribution over a large surface area, a characteristic exploited in standard refractometric sensing. However, their application to polarization-sensitive investigations is not straightforward because the transverse electric (TE) and magnetic (TM) surface modes possess distinct dispersion relations, therefore their relative phase is not conserved along propagation and the polarization state of any wave obtained by combining these modes is ill-defined. In this work, a novel design of a 1DPC is realized in which the TE and TM modes exhibit the same phase velocity over a broadband spectral range and thus their dispersion relations overlap. The capability to simultaneously excite TE and TM modes with a well-defined phase relation allows the generation of surface waves with a controlled polarization state. This paves the way to polarization-resolved surface-enhanced analysis, including, for example, linear and circular dichroism spectroscopy of grafted molecular layers at the photonic crystal surface.

August, 2022 · DOI: 10.1002/adom.202200759

Química de Superficies y Catálisis

Emerging natural and tailored perovskite-type mixed oxides-based catalysts for CO2 conversions

Wu, J; Ye, RP; Xu, DJ; Wan, LZ; Reina, TR; Sun, H; Ni, Y; Zhou, ZF; Deng, XAFrontiers in Chemistry, 10 (2022) 961355 DOI: 10.3389/fchem.2022.961355

Abstract

The rapid economic and societal development have led to unprecedented energy demand and consumption resulting in the harmful emission of pollutants. Hence, the conversion of greenhouse gases into valuable chemicals and fuels has become an urgent challenge for the scientific community. In recent decades, perovskite-type mixed oxide-based catalysts have attracted significant attention as efficient CO2 conversion catalysts due to the characteristics of both reversible oxygen storage capacity and stable structure compared to traditional oxide-supported catalysts. In this review, we hand over a comprehensive overview of the research for CO2 conversion by these emerging perovskite-type mixed oxide-based catalysts. Three main CO2 conversions, namely reverse water gas shift reaction, CO2 methanation, and CO2 reforming of methane have been introduced over perovskite-type mixed oxide-based catalysts and their reaction mechanisms. Different approaches for promoting activity and resisting carbon deposition have also been discussed, involving increased oxygen vacancies, enhanced dispersion of active metal, and fine-tuning strong metal-support interactions. Finally, the current challenges are mooted, and we have proposed future research prospects in this field to inspire more sensational breakthroughs in the material and environment fields.

August, 2022 · DOI: 10.3389/fchem.2022.961355

Reactividad de Sólidos

Overlooked pitfalls in CaO carbonation kinetics studies nearby equilibrium: Instrumental effects on calculated kinetic rate constants

Arcenegui-Troya, J; Duran-Martin, JD; Perejon, A; Valverde, JM; Maqueda, LAP; Jimenez, PESAlexandria Engineering Journal, 61 (2022) 6129-6138 DOI: 10.1016/j.aej.2021.11.043

Abstract

Due to its technological applications, such as CO2 capture, CaO carbonation kinetics has been extensively studied using a wide array of methods and experimental conditions. A complete understanding of carbonation kinetics is key to optimizing the operating conditions as well as to correctly design the carbonation reactor. However, there is yet no consensus on the reaction model and kinetic parameters that can best describe the CaO carbonation reaction. For instance, the value of the activation energy proposed in different works can vary up to 300%. In this work, we demonstrate that the strong influence of the thermodynamic equilibrium on CaO carbonation kinetics demands careful control of the experimental conditions to obtain meaningful kinetic parameters. Specifically, we explore the influence of three experimental parameters on carbonation kinetics: the gas flow rate, the CO2 partial pressure and the time required to fill the reactor after a gas change. We demonstrate that disregarding these aspects may lead to bogus conclusions on reaction kinetics, which could partly explain the considerable discrepancies found in the literature. The conclusions of this work are not only applicable to the process and experimental setup studied here but also to any study that involves the use of gas flow to drive a reaction.

August, 2022 · DOI: 10.1016/j.aej.2021.11.043

Materiales Avanzados

Chemical, Radiometric and Mechanical Characterization of Commercial Polymeric Films for Greenhouse Applications

Franco, JE; Rodríguez-Arroyo, JA; Ortiz, IM; Sánchez-Soto, PJ; Garzón, E; Lao, MTMaterials, 15 (2022) 5532 DOI: 10.3390/ma15165532

Abstract

In the agricultural sector, companies involved in the production of plastic greenhouses are currently searching for a suitable covering adapted for every climate in the world. For this purpose, this research work has determined the chemical, radiometric and mechanical properties of 53 polymeric films samples from Europe and South America. The chemical tests carried out with these samples were elemental analysis (C, H and N) and FT-IR spectrometry. The radiometric properties here studied were the transmission, absorption and reflection coefficients along the spectrum between 300 and 1100 nm. For the mechanical properties, tensile strength, tear strength and dart impact strength, tests were carried out. Finally, all these data were collected, and a multivariate statistical analysis was carried out using the SPSS statistical to group the samples into statistical groups adapted to specific climatic regions. The elemental analysis and FT-IR spectrometry allowed group the samples into nine groups. The samples were grouped according to their chemical (elemental analysis), radiometric and mechanical properties by multivariate analysis. The dendrogram separated five very different groups in terms of number of samples. These groups have specific chemical, radiometric and mechanical characteristics that separate them from the rest. These groups make it possible to narrow down the applications and correlate with the radiometric properties to see in which geographical area of the world they are most effective in increasing yields and achieving higher quality production.

August, 2022 · DOI: 10.3390/ma15165532

Química de Superficies y Catálisis

Feasibility of switchable dual function materials as a flexible technology for CO2 capture and utilisation and evidence of passive direct air capture

Merkouri, LP; Reina, TR; Duyar, MSNanoscale, 14 (2022) 12620-12637 DOI: 10.1039/d2nr02688k

Abstract

The feasibility of a Dual Function Material (DFM) with a versatile catalyst offering switchable chemical synthesis from carbon dioxide (CO2) was demonstrated for the first time, showing evidence of the ability of these DFMs to passively capture CO2 directly from the air as well. These DFMs open up possibilities in flexible chemical production from dilute sources of CO2, through a combination of CO2 adsorption and subsequent chemical transformation (methanation, reverse water gas shift or dry reforming of methane). Combinations of Ni Ru bimetallic catalyst with Na2O, K2O or CaO adsorbent were supported on CeO2-Al2O3 to develop flexible DFMs. The designed multicomponent materials were shown to reversibly adsorb CO2 between the 350 and 650 degrees C temperature range and were easily regenerated by an inert gas purge stream. The components of the flexible DFMs showed a high degree of interaction with each other, which evidently enhanced their CO2 capture performance ranging from 0.14 to 0.49 mol kg(-1). It was shown that captured CO2 could be converted into useful products through either CO2 methanation, reverse water-gas shift (RWGS) or dry reforming of methane (DRM), which provides flexibility in terms of co-reactant (hydrogen vs. methane) and end product (synthetic natural gas, syngas or CO) by adjusting reaction conditions. The best DFM was the one containing CaO, producing 104 mu mol of CH4 per kg(DFM) in CO2 methanation, 58 mu mol of CO per kg(DFM) in RWGS and 338 mu mol of CO per kg(DFM) in DRM.

August, 2022 · DOI: 10.1039/d2nr02688k

Materiales Avanzados

Assessment of construction and demolition wastes (CDWs) as raw materials for the manufacture of low-strength concrete and bases and sub-bases of roads

Garzon, E; Martinez-Martinez, S; Perez-Villarrejo, L; Sanchez-Soto, PJMaterials Letters, 320 (2022) 132343 DOI: 10.1016/j.matlet.2022.132343

Abstract

A chemical (XRF) and mineralogical (XRD) characterisation has been carried out, as well as the determination of the main properties, of construction and demolition wastes (CDWs). This waste has been applied as recycled aggregate. The objective was to search for its reuse for the manufacture of concrete and road bases and sub-bases. Chemical analysis revealed the presence of SiO2 (39.13 wt%) and Al2O3 (9.55 wt%) from quartz and some silicates, and gypsum. The content of CaO (21.42 wt%) was associated with calcite and dolomite. The materials' properties have suggested that the particle sizes are not inside the typical interval fixed in the Spanish normative. It can be reused as esplanades or sub-bases of roads and highways, since it is a granular material with a very high California Bearing Ratio (CBR value is 36). It was concluded that the use of CDWs as a substitute of sand for the manufacture of concrete can only be used in percentages lower than 10 wt% producing low-strength concrete.

August, 2022 · DOI: 10.1016/j.matlet.2022.132343

Materiales Coloidales

Outstanding MRI contrast with dysprosium phosphate nanoparticles of tuneable size

Gómez-González, E.; Caro, C.; García-Martín, ML; Becerro, AI; Ocaña, M.Nanoscale, 14 (2022) 11461-11470 DOI: 10.1039/d2nr02630a

Abstract

The use of high-field magnets for magnetic resonance imaging (MRI) is expected to experience the fastest growth rate during the present decade. Although several CAs for MRI scanners using high magnetic fields have been reported, they are mostly based on fluoride matrices, which are known for their low chemical stability in aqueous suspensions. Chemically stable MRI CAs for high-field magnets are therefore needed to enable the advances in MRI technique. Herein, we synthesized uniform DyPO4 nanoparticles (NPs) with tuneable sizes between 23 and 57 nm using homogeneous precipitation in butanol. The NPs were successfully functionalized with polyacrylic acid (PAA) and showed good colloidal stability in aqueous suspensions. Chemical stability was also assessed in PBS, showing negligible solubility. The effect of particle size on the transversal relaxivity value (r(2)) was further explored at 9.4 T, finding a clear increase in r(2) with particle size. The r(2) value found for the largest NPs was 516 mM(-1) s(-1), which is, to the best of our knowledge, the highest r(2) value ever reported at 9.4 T for any Dy-based nanometric particles in the literature. Finally, the latter NPs were submitted to biosafety studies after polyethylene glycol (PEG) functionalization. Cell morphology, induction of necrotic/late apoptotic cells, and mitochondrial activity were thoroughly analyzed. The results clearly indicated negligible toxicity effects under the assayed conditions. Short- and long-term in vivo pharmacokinetics of the intravenously injected NPs were assessed by dynamic T-2-weighted MRI and quantitative T-2 mapping, revealing faster liver than spleen uptake, while no accumulation was observed in the kidneys. Finally, no histopathological changes were observed in any of the studied organs, including the liver, kidney, spleen, and lung, which provide further evidence of the biocompatibility of DyPO4 NPs and, therefore, their suitability as bioimaging probes.

August, 2022 · DOI: 10.1039/d2nr02630a

Materiales y Procesos Catalíticos de Interés Ambiental y Energético

Shepherding reaction intermediates to optimize H-2 yield using composite-doped TiO2-based photocatalysts

Barba-Nieto, I.; Colon, G; Fernández-García, M; Kubacka, AChemical Engineering Journal, 442 (2022) 136333 DOI: 10.1016/j.cej.2022.136333

Abstract

Optimization of Pt-promoted TiO2-based is key to promote the photocatalytic production of hydrogen using sacrificial alcohol molecules. Combination of doping and surface decoration of the mentioned base photoactive material is here exploited to maximize hydrogen yield. Using the quantum efficiency parameter, it is shown that the resulting composite system can boost activity up to 7.3 times within the whole methanol:water mixture ratio, yielding quantum efficiencies in the ca. 13-16 % range. The key role of the different components in generating charge carrier species and their use to trigger the sacrificial molecule evolution and control reaction kinetics are examined through an in-situ spectroscopic study. The study unveils the complex reaction mechanism, with generation of C1 to C3 molecules from different carbon-containing radicals, and interprets the physical origin of the huge H2 production enhancement occurring in doped-composite titania-based catalysts.

August, 2022 · DOI: 10.1016/j.cej.2022.136333

Química de Superficies y Catálisis

Catalytic reforming of model biomass-derived producer gas

Azancot, L; Bobadilla, LF; Centeno, MA; Odriozola, JAFuel, 320 (2022) 123843 DOI: 10.1016/j.fuel.2022.123843

Abstract

This work includes a complete study of the reaction of reforming a simulated producer gas stream comparing a Ni-based catalyst with another one promoted with potassium to enhance the resistance to coke formation. Although coke deposition is unavoidable in the presence of tars in the stream, the analysis of different reaction parameters revealed that operating at 750 degrees C, weight hourly space velocity (WHSV) of 60 L-1 g(-1) h(-1) and 10-20 vol% of steam is possible to minimize the accumulation of carbon deposits. Moreover, it was demonstrated that the addition of potassium helps to mitigate carbon formation, but a high concentration of steam leads to nickel sintering and/or partial oxidation of metallic nickel. On this basis, it was successfully evidenced that the Ni-K catalyst is an excellent candidate for obtaining clean syngas from producer gas reforming.

July, 2022 · DOI: 10.1016/j.fuel.2022.123843

Materiales de Diseño para la Energía y Medioambiente

Flame confinement in biomass combustion systems for particles abatement

Ciria, D; Orihuela, MP; Moreno-Naranjo, P; Chacartegui, R; Ramirez-Rico, J; Becerra, JAEnergy Conversion and Management, 264 (2022) 115706 DOI: 10.1016/j.enconman.2022.115706

Abstract

This work explores the use of open-pore, inert ceramic foams with different pore sizes as particle abatement systems in small biomass combustion systems. Porous foams made of silicon carbide with pore sizes 10 to 60 pores-per-inch were installed in an in-house designed combustion unit operated with wood pellets. Their effects on the temperature distribution inside the chamber, particulate and gases emissions were studied using different airflow rates in the reaction-limited regime (low equivalence ratio) to minimise stoichiometric factors. The influence of pore size, foam position with respect to the flame and space velocity were assessed. The confinement of the flame with inert foams was found to substantially modify the temperature distribution in the combustion chamber, improve the air-fuel mixture, and favour the thermal decomposition of the pellet, leading to a reduction in particulate emissions when compared to free-flame combustion at the same experimental conditions. In general, the amount of particulate matter was found to decrease by up to one order of magnitude as the pore size of the foam was reduced, while the temperature gradient in the combustion chamber was increased. Nitrogen oxides and carbon dioxide emissions were essentially unchanged, irrespectively of the pore size of the foam. It is expected that these values will be improved with longer residence times, as happens in operations with reduced excess air ratios. These results suggest that it is possible to control pollutants derived from domestic heating within the most restrictive current regulations on particulate emissions by integrating flame confinement designs with better operating practices and efficient abatement systems.

July, 2022 · DOI: 10.1016/j.enconman.2022.115706

Reactividad de Sólidos

Albero: An alternative natural material for solar energy storage by the calcium-looping process

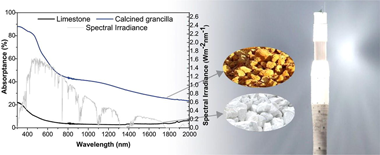

Moreno, V; Arcenegui-Troya, J; Sanchez-Jimenez, P; Perejon, A; Chacartegui, R; Valverde, JM; Perez-Maqueda, LAChemical Engineering Journal, 440 (2022) 135707 DOI: 10.1016/j.cej.2022.135707

Abstract

Large-scale thermochemical energy storage (TCES) is gaining relevance as an alternative to current thermal energy storage systems in Concentrated Solar Power plants. Among the different systems, the reversible reaction between CaO and CO2 stands out due to the wide availability and low cost of the raw material: limestone. Direct solar absorption of the storage media would improve the efficiency of solar-to-thermal energy storage due to reduced thermal transfer barriers, but the solar optical absorption of CaCO3 is poor. In this work, we propose the use of a Ca-rich calcarenite sedimentary rock so-called albem as an alternative to limestone. We demonstrate that this reddish material exhibits an average solar absorptance that is approximately ten times larger than limestone. Moreover, the multicycle carbonation/calcination performance under different experimental conditions has been studied by thermogravimetry, and similar values to those exhibited for limestone have been obtained. Besides, the material is cheap (6 Elton), and simulations showed that the use of this material would significantly improve the overall CaL-CSP efficiency at the industrial level.

July, 2022 · DOI: 10.1016/j.cej.2022.135707

Materiales Nanoestructurados y Microestructura

Ultrathin Plasma Polymer Passivation of Perovskite Solar Cells for Improved Stability and Reproducibility

Obrero-Perez, JM; Contreras-Bernal, L; Nuñez-Galvez, F; Castillo-Seoane, J; Valadez-Villalobos, K; Aparicio, FJ; Anta, JA; Borras, A; Sanchez-Valencia, JR; Barranco, AAdvanced Energy Materials, (2022) 2200812 DOI: 10.1002/aenm.202200812

Abstract

Despite the youthfulness of hybrid halide perovskite solar cells, their efficiencies are currently comparable to commercial silicon and have surpassed quantum-dots solar cells. Yet, the scalability of these devices is a challenge due to their low reproducibility and stability under environmental conditions. However, the techniques reported to date to tackle such issues recurrently involve the use of solvent methods that would further complicate their transfer to industry. Herein a reliable alternative relaying in the implementation of an ultrathin plasma polymer as a passivation interface between the electron transport layer and the hybrid perovskite layer is presented. Such a nanoengineered interface provides solar devices with increased long-term stability under ambient conditions. Thus, without involving any additional encapsulation step, the cells retain more than 80% of their efficiency after being exposed to the ambient atmosphere for more than 1000 h. Moreover, this plasma polymer passivation strategy significantly improves the coverage of the mesoporous scaffold by the perovskite layer, providing the solar cells with enhanced performance, with a champion efficiency of 19.2%, a remarkable value for Li-free standard mesoporous n-i-p architectures, as well as significantly improved reproducibility.

July, 2022 · DOI: 10.1002/aenm.202200812

Fotocatálisis Heterogénea: Aplicaciones

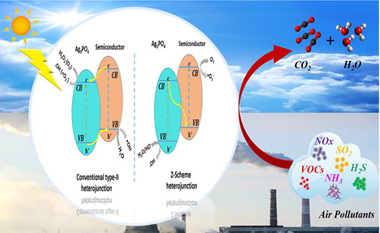

Photocatalytic oxidation of pollutants in gas-phase via Ag3PO4-based semiconductor photocatalysts: Recent progress, new trends, and future perspectives

Y. Naciri; A. Hsini; A. Bouziani; R. Djellabi; Z. Ajmal; M. Laabd; J.A. Navío; A. Mills; C.L. Bianchi; H.Li; B. Bakiz; A. AlbourineCritical Reviews in Environmental Science and Technology, 52 (2022) 2339-2382 DOI: 10.1080/10643389.2021.1877977

Abstract

Air pollution has become a significant challenge for both developing and developed nations. due to its close association with numerous fatal diseases such as cancer, respiratory, heart attack, and brain stroke. Over recent years, heterogeneous semiconductor photocatalysis has emerged as an effective approach to air remediation due to the ease of scale-up, ready application in the field, use of solar light and ready availability of a number of different effective photocatalysts. To date, most work in this area has been conducted using UV-absorbing photocatalysts, such as TiO2 and ZnO; However, recent studies have revealed Ag3PO4 as an attractive, visible-light-absorbing alternative, with a bandgap of 2.43 eV. In particular, this material has been shown to be an excellent photocatalyst for the removal of many types of pollutants in the gas phase. However, the widespread application of Ag3PO4 is restricted due to its tendency to undergo photoanodic corrosion and the poor reducing power of its photogenerated conductance band electrons, which are unable to reduce O2 to superoxide •O2 −. These limitations are critically evaluated in this review. In addition, recent studies on the modification of Ag3PO4 via combination with the conventional heterojunctions or Z-scheme junctions, as well as the photocatalytic mechanistic pathways for enhanced gas-pollutants removal, are summarized and discussed. Finally, an overview is given on the future developments that are required in order to overcome these challenges and so stimulate further research into this promising field.

July, 2022 · DOI: 10.1080/10643389.2021.1877977

Química de Superficies y Catálisis

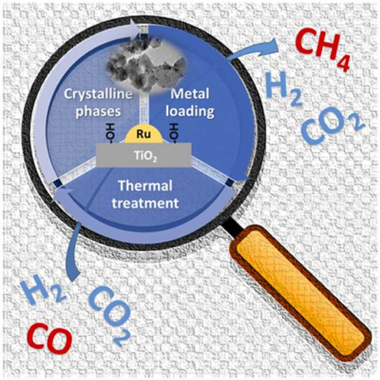

The effect of support surface hydroxyls on selective CO methanation with Ru based catalysts

Martínez, LMT; Muñoza, A; Pérez, A; Laguna, OH; Bobadilla, LF; Centeno, MA; Odriozola, JAApplied Catalysis A: General, 641 (2022) 118678 DOI: 10.1016/j.apcata.2022.118678

Abstract

The aim of this work was to clarify the effect of the support on CO selective methanation with Ru/TiO2 catalysts. TPR, XRD and TEM measurements confirmed that the changes in the activity and selectivity should be ascribed to anatase:rutile ratio, RuO2 +TiO2 solid solution formation, as well as the metal content and the thermal treatment used. All these characteristics result in active and selective catalysts in which the suppression of the reverse water gas shift reaction was observed. The catalytic performance must be explained by both the formation of more active Ru species as a result of support influence and the higher Ru dispersion. The study allows to conclude that for CO activation the role of support surface hydroxyls seems to be determinant for both the activity and selectivity of Ru/TiO2 catalysts.

July, 2022 · DOI: 10.1016/j.apcata.2022.118678

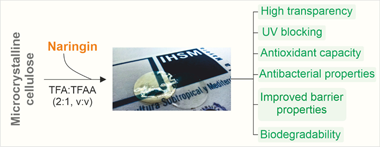

Materiales de Diseño para la Energía y Medioambiente

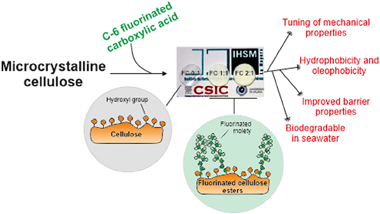

Greaseproof, hydrophobic, and biodegradable food packaging bioplastics from C6-fluorinated cellulose esters

Guzman-Puyol, S; Tedeschi, G; Goldoni, L; Benitez, JJ; Ceseracciu, L; Koschella, A; Heinze, T; Athanassiou, A; Heredia-Guerrera, JAFood Hydrocolloids, 128 (2022) 107562 DOI: 10.1016/j.foodhyd.2022.107562

Abstract

Tridecafluorononanoic acid (TFNA), a C6-fluorinated carboxylic acid, was esterified with cellulose at different molar ratios (0:1, 1:1, 2:1, and 3:1) in a trifluoroacetic acid (TFA):trifluoroacetic anhydride (TFAA):CHCl3 (2:1:1, v:v:v) solvent mixture. Free-standing films were obtained for all formulations and are presented as alternatives to composites and blends of paper with fluorinated molecules. Mechanical properties were investigated by tensile tests, and a plasticizer effect of fluorinated chains was observed. Interestingly, the wettability of these new cellulose derivatives was similar or even better than other common cellulose derivatives and fluorinated poly-mers employed in food packaging. Hydrodynamic properties were also improved by addition of TFNA, resulting in materials with water vapor permeability values comparable to other cellulose-based food packaging materials. In addition, films with the higher amounts of TFNA showed the required oil resistance for papers used in food packaging applications, as determined by the Kit Test. Finally, the biodegradation of these C6-fluorinated cel-lulose esters, assessed by biological oxygen demand (BOD) in seawater, was higher than typical bio-based polymers used in food packaging. The bioplastic synthesized at a molar ratio 1:1 (TFNA:cellulose) showed excellent performances in terms of greaseproof, hydrophobicity, ductility, and biodegradability, representing a sustainable alternative to typical plastics used in food packaging.

July, 2022 · DOI: 10.1016/j.foodhyd.2022.107562

Química de Superficies y Catálisis

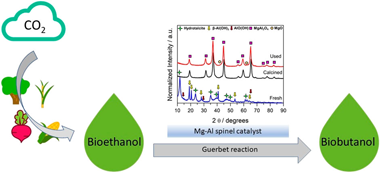

Insights on Guerbet Reaction: Production of Biobutanol From Bioethanol Over a Mg-Al Spinel Catalyst

Crespo, MAP; Vidal-Barrero, F; Azancot, L; Reina, TR; Campoy, MFrontiers in Chemistry, 10 (2022) 945596 DOI: 10.3389/fchem.2022.945596

Abstract

The production of biobutanol from bioethanol by the Guerbet reaction is an alternative pathway to renewable sources. The commercial viability of this green route requires improvements in the process development. This study experimentally examines the influence of operating conditions on the performance of a Mg-Al spinel catalyst prepared from hydrotalcite precursors. This catalyst demonstrates an exceptional performance in the Guerbet reaction with a promising activity/butanol selectivity balance, excellent long-term stability, and very-low-carbon footprint (CO2 generation as by-products is minimal). This study showcases a systematic strategy to optimize the reaction parameters in the Guerbet reaction for biobutanol production using an advanced spinel catalyst. Upon carefully adjusting temperature, pressure, space velocity, and reactants co-feeding, very promising conversion (35%) and butanol selectivity values (48%) were obtained.

July, 2022 · DOI: 10.3389/fchem.2022.945596

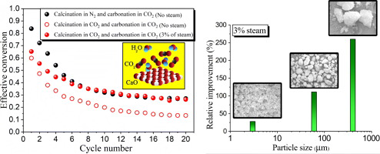

Reactividad de Sólidos

Steam-enhanced calcium-looping performance of limestone for thermochemical energy storage: The role of particle size

Arcenegui-Troya, J.; Sánchez-Jiménez, PE; Perejon, A; Valverde, JM; Pérez-Maqueda, LAJournal of Energy Storage, 51 (2022) 104305 DOI: 10.1016/j.est.2022.104305

Abstract

Steam injection has been proposed to attenuate the decay of CaO reactivity during calcium looping (CaL) under operating conditions compatible with carbon capture and storage. However, it is yet unknown whether the perceived advantages granted by steam hold under the distinct operating conditions required for the integration of the CaL process as a thermochemical energy storage system in Concentrating Solar Power Plants (CaL-CSP). Here, we study the influence of steam in conditions compatible with a CaL-CSP scheme and assess its impact when injected only during one stage; either calcination or carbonation, and also when it is present throughout the entire loop. The results presented here demonstrate that steam boosts the CaO multicycle performance in a CO2 closed loop to attain residual conversion values similar to those achieved at moderate temperatures under inert gas. Moreover, it is found that the enhancement in multicycle activity is more pronounced for larger particles.

July, 2022 · DOI: 10.1016/j.est.2022.104305

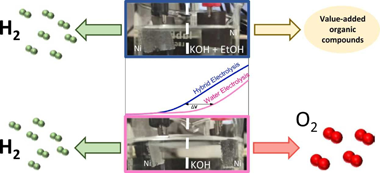

Nanotecnología en Superficies y Plasma

Nanostructured nickel based electrocatalysts for hybrid ethanol-water anion exchange membrane electrolysis

Lopez-Fernandez, E; Gomez-Sacedon, C; Gil-Rostra, J; Espinos, JP; Gonzalez-Elipe, AR; Yubero, FJournal of Environmental Chemical Engineering, 10 (2022) 107994 DOI: 10.1016/j.jece.2022.107994

Abstract

Ni and Ni-Fe nanostructured layers prepared by magnetron sputtering in an oblique angle deposition configuration (MS-OAD) have been used as anode and cathode catalysts for hybrid ethanol-water electrolysis in an anion exchange membrane (AEM) electrolyser. Physico-chemical and electrochemical characterization in a threeelectrode cell has been carried out to determine the optimal characteristics of the anodic films. Current densities up to 434 mA cm-2 at 2.0 V in a 1.5 M EtOH and 2.0 M KOH fuel solution were achieved with excellent operational stability for 3 days. These experiments show that the oxygen evolution reaction taking place at the anode is completely replaced by the ethanol oxidation reaction under our explored reaction conditions. The obtained results evidence the interest of this kind of organic vs. pure water electrolysis to decrease the overall electrical energy consumption for the production of hydrogen.

June, 2022 · DOI: 10.1016/j.jece.2022.107994

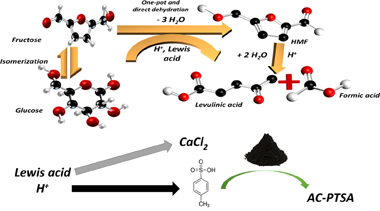

Fotocatálisis Heterogénea: Aplicaciones

Pursuing efficient systems for glucose transformation to levulinic acid: Homogeneous vs. heterogeneous catalysts and the effect of their co-action

Bounoukta, CE; Megias-Sayago, C; Ivanova, S; Ammari, F; Centeno, MA; Odriozola, JAFUEL, 318 (2022) 123712 DOI: 10.1016/j.fuel.2022.123712

Abstract

Exploring available catalytic systems to understand their behavior is a must to properly design efficient catalysts aiming to definitively drive biomass from laboratory to industrial scale. Glucose transformation to levulinic acid involves cascade reactions with specific requirements, different active sites in each case and secondary reactions hard to avoid which are intrinsically linked to the catalyst's nature and reaction conditions. In the present work, homogeneous, heterogeneous and heterogeneous/homogeneous catalysts are considered with the unique goal of improving levulinic acid yield while understanding the catalytic behaviour of cost-effective catalysts. The choice of the catalytic systems and the effect of the main reaction parameters on activity and selectivity is studied and discussed.

June, 2022 · DOI: 10.1016/j.fuel.2022.123712

Materiales Avanzados

Vitrification rate and estimation of the optimum firing conditions of ceramic materials from raw clays: A review

Garzon, E; Perez-Villarejo, L; Eliche-Quesada, D; Martinez-Martinez, S; Sanchez-Soto, PJCeramics International, 48 (2022) 15889-15898 DOI: 10.1016/j.ceramint.2022.02.129

Abstract

The present work is a review concerning the previous investigations on the vitrification behaviour of clays containing kaolinite, feldspars, muscovite (illite/sericite) and pyrophyllite. These clays are silico-aluminous and have interesting properties as raw materials for structural ceramics. The mineralogical and chemical composition were determined. Then, the vitrification in these clay samples using pressed bodies was investigated by few researchers in the temperature range 800-1350 degrees C with 0.5-5.5 h of soaking times. The effect of heat treatments on the degree of vitrification in these clays was characterized by bulk densities of the ceramic bodies at the fired stage. It was found some variations of bulk density values for all these clays fired in the range 1000-1150 degrees C, with marked decreases of the values obtained at 1200 degrees C and 1300 degrees C. A first order reaction kinetics was applied to the analysis of vitrification of the ceramic bodies under isothermal heating. The method is based on experi-mental data of bulk densities, being proposed for the estimation of the relative degree of vitrification resulting from different firing schedules. The analysis considered the temperature dependence of the rate of vitrification following Arrhenius behaviour. Thus, the vitrification activation energy can be obtained. The activation energies for the physical process of vitrification in these clays ranged from 45 to 151 kJ/mol. The relative rates of vitrification or degree of vitrification attained during heating and soaking were calculated. The results suggested that the contribution of vitrification due to heating in all these clays was relatively small compared to the vitrification during soaking. However, it was evidenced that the influence of the particle sizes in the thermal behaviour of these clays cannot be neglected. The vitrification rate equations, as deduced in these previous studies, can be useful tools to estimate the optimum firing conditions of these clays, allowing the extension of this method to other clay types.

June, 2022 · DOI: 10.1016/j.ceramint.2022.02.129

Química de Superficies y Catálisis

Design of Full-Temperature-Range RWGS Catalysts: Impact of Alkali Promoters on Ni/CeO2

Gandara-Loe, J; Zhang, Q; Villora-Pico, JJ; Sepulveda-Escribano, A; Pastor-Perez, L; Reina, TREnergy & Fuels, 36 (2022) 6362-6373 DOI: 10.1021/acs.energyfuels.2c00784

Abstract

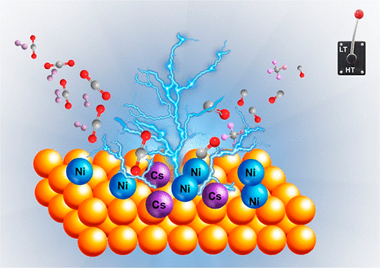

Reverse water gas shift (RWGS) competes with methanation as a direct pathway in the CO2 recycling route, with methanation being a dominant process in the low-temperature window and RWGS at higher temperatures. This work showcases the design of multi-component catalysts for a full-temperature-range RWGS behavior by suppressing the methanation reaction at low temperatures. The addition of alkali promoters (Na, K, and Cs) to the reference Ni/CeO2 catalyst allows identifying a clear trend in RWGS activation promotion in both low- and high-temperature ranges. Our characterization data evidence changes in the electronic, structural, and textural properties of the reference catalyst when promoted with selected dopants. Such modifications are crucial to displaying an advanced RWGS performance. Among the studied promoters, Cs leads to a more substantial impact on the catalytic activity. Beyond the improved CO selectivity, our best performing catalyst maintains high conversion levels for long-term runs in cyclable temperature ranges, showcasing the versatility of this catalyst for different operating conditions. All in all, this work provides an illustrative example of the impact of promoters on fine-tuning the selectivity of a CO2 conversion process, opening new opportunities for CO2 utilization strategies enabled by multi-component catalysts.

June, 2022 · DOI: 10.1021/acs.energyfuels.2c00784

Química de Superficies y Catálisis

Electrocatalytic CO2 conversion to C-2 products: Catalysts design, market perspectives and techno-economic aspects

Ruiz-López, E; Gandara-Loe, J; Baena-Moreno, F; Reina, TR; Odriozola, JARenewable & Sustainable Energy Reviews, 161 (2022) 112329 DOI: 10.1016/j.rser.2022.112329

Abstract

The energy crisis caused by the incessant growth in global energy demand joint to its associated greenhouse emissions motivates the urgent need to control and mitigate atmospheric CO2 levels. Leveraging CO2 as carbon pool to produce value-added products represents a cornerstone of the circular economy. Among the CO2 utilization strategies, electrochemical reduction of CO2 conversion to produce fuels and chemicals is booming due to its versatility and end-product flexibility. Herein most of the studies focused on C-1 products although C-2 and C2+ compounds are chemically and economically more appealing targets requiring advanced catalytic materials. Still, despite the complex pathways for C2+ products formation, their multiple and assorted applications have motivated the search of suitable electrocatalysts. In this review, we gather and analyse in a comprehensive manner the progress made regarding C2+ products considering not only the catalyst design and the electrochemistry features but also techno-economic aspects in order to envisage the most profitable scenarios. This state-of-the-art analysis showcases that electrochemical reduction of CO2 to C-2 products will play a key role in the decarbonisation of the chemical industry paving the way towards a low-carbon future.

June, 2022 · DOI: 10.1016/j.rser.2022.112329

Materiales y Procesos Catalíticos de Interés Ambiental y Energético

Enhanced photocatalytic activity of TiO2/WO3 nanocomposite from sonochemical-microwave assisted synthesis for the photodegradation of ciprofloxacin and oxytetracycline antibiotics under UV and sunlight

Moghni, N; Boutoumi, H; Khalaf, H; Makaoui, N; Colon, GJournal of Photochemistry and Photobiology A-Chemistry, 428 (2022) 113848 DOI: 10.1016/j.jphotochem.2022.113848

Abstract

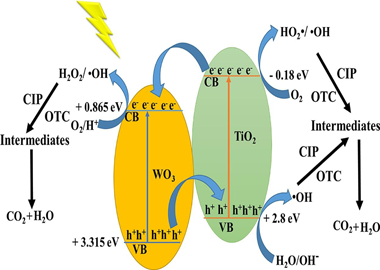

The TiO2/WO3 photocatalysts were prepared by a simple assisted sonochemical -microwave combination. The wide surface and structural characterization of synthesized material confirmed that the adopted preparation method resulted in nanoparticulated crystallite anatase phase of TiO2 with a large surface area (> 200 m(2)/g), and the dispersion of WO3 on the surface of TiO2. The photoactivity was assessed for the photodegradation of ciprofloxacin (CIP) and oxytetracycline (OTC) antibiotics under UV and sunlight irradiation. The mineralization rate, toxicity assessment, pollutant concentration effect on photodegradation efficiency, and reusability potential under sunlight were all investigated. Results showed that TiO2 doped with 5 wt% of WO3 exhibited the best photocatalytic activity under UV (100% degradation) and solar light. Rate constants for CIP and OTC degradation showed that TiO2/WO3 significantly improved with respect to bare TiO2. The antibacterial study revealed that the photodegraded solutions became less toxic than the initial CIP and OTC solutions showing a significant decrease in the inhibition zone diameter and mineralization rates. The prepared TiO2/WO3 maintained high performances in the presence of high concentrations of pollutants as well as good stability after four consecutive uses. The increased photocatalytic activity is attributed to the incorporation of WO3, which extends the light absorption range and decreases the rate of electron -hole recombination.

June, 2022 · DOI: 10.1016/j.jphotochem.2022.113848

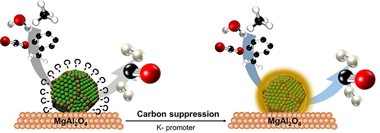

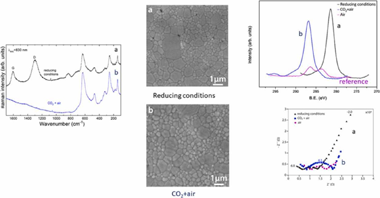

Química de Superficies y Catálisis

Evidence of new Ni-O-K catalytic sites with superior stability for methane dry reforming

Azancot, L; Blay, V; Blay-Roger, R; Bobadilla, LF; Penkova, A; Centeno, MA; Odriozola, JAApplied Catalysis B-Environmental, 307 (2022) 121148 DOI: 10.1016/j.apcatb.2022.121148

Abstract

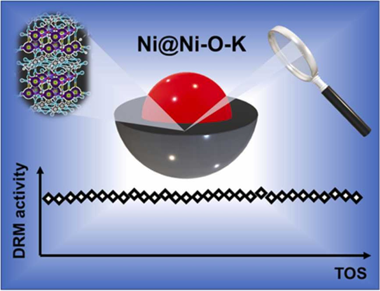

Liquid fuels produced via Fischer-Tropsch synthesis from biomass-derived syngas constitute an attractive and sustainable energy vector for the transportation sector. This study focuses on the role of potassium as a promoter in Ni-based catalysts for reducing coke deposition during catalytic dry reforming. The study provides a new structural link between catalytic performance and physicochemical properties. We identify new Ni-O-K chemical states associated with high stability in the reforming process, evidenced by different characterization techniques. The nickel particles form a core surrounded by a Ni-O-K phase layer (Ni@Ni-O-K) during the reduction of the catalyst. This phase likely presents an alkali-nickelate-type structure, in which nickel is stabilized in oxidation state + 3. The Ni-O-K formation induces essential changes in the electronic, physical, structural, and morphological properties of the catalysts, notably enhancing their long-term stability in dry reforming. This work thus provides new directions for designing more efficient catalysts for sustainable gas-to-liquids processes.

June, 2022 · DOI: 10.1016/j.apcatb.2022.121148

Reduction of N2O with hydrosilanes catalysed by RuSNS nanoparticles

Molinillo, P; Lacroix, B; Vattier, F; Rendon, N; Suarez, A; Lara, PChemical Communications DOI: 10.1039/d2cc01470j

Abstract

A series of RuSNS nanoparticles, prepared by decomposition of Ru(COD)(COT) with H-2 in the presence of an SNS ligand, have been found to catalyse the reduction of the greenhouse gas N2O to N-2 employing different hydrosilanes.

June, 2022 · DOI: 10.1039/d2cc01470j

Materiales Ópticos Multifuncionales

Effect of Spatial Inhomogeneity on Quantum Trapping

Esteso, V; Carretero-Palacios, S; Miguez, HJournal of Physical Chemistry Letters, 13 (2022) 4513-4519 DOI: 10.1021/acs.jpclett.2c00807

Abstract

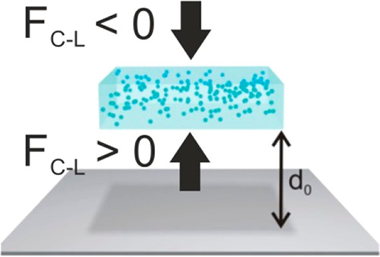

An object that is immersed in afluid and approaching a substrate mayfind apotential energy minimum at a certain distance due to the balance between attractive and repulsiveCasimir-Lifshitz forces, a phenomenon referred to as quantum trapping. This equilibriumdepends on the relative values of the dielectric functions of the materials involved. Herein, westudy quantum trapping effects in planar nanocomposite materials and demonstrate that they arestrongly dependent on the characteristics of the spatial inhomogeneity. As a model case, weconsider spherical particles embedded in an otherwise homogeneous material. We propose aneffective medium approximation that accounts for the effect of inclusions andfind that anunprecedented and counterintuitive intense repulsive Casimir-Lifshitz force arises as a result ofthe strong optical scattering and absorption size-dependent resonances caused by their presence. Our results imply that the properanalysis of quantum trapping effects requires comprehensive knowledge and a detailed description of the potential inhomogeneity(caused by imperfections, pores, inclusions, and density variations) present in the materials involved

June, 2022 · DOI: 10.1021/acs.jpclett.2c00807

Nanotecnología en Superficies y Plasma

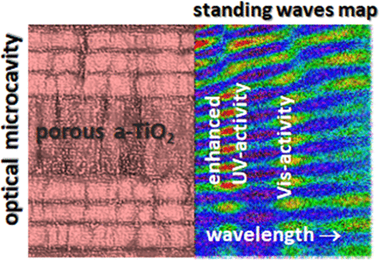

Titania Enhanced Photocatalysis and Dye Giant Absorption in Nanoporous 1D Bragg Microcavities

Rico, VJ; Turk, H; Yubero, F; González-Elipe, ARACS Applied Nano Materials, 5 (2022) 5487-5497 DOI: 10.1021/acsanm.2c00477

Abstract

Light trapping effects are known to boost the photocatalytic degradation of organic molecules in 3D photonic structures of anatase titania (a-TiO2) with an inverse opal configuration. In the present work, we show that photocatalytic activity can also be enhanced in a-TiO2 thin films if they are incorporated within a nanoporous 1D optical resonant microcavity. We have designed and manufactured multilayer systems that, presenting a high open porosity to enable a straightforward diffusion of photodegradable molecules, provide light confinement effects at wavelengths around the absorption edge of photoactive a-TiO2. In brief, we have observed that a nanoporous 1D Bragg microcavity prepared by electron beam evaporation at oblique angles comprising a central defect layer of nanoporous a-TiO2 boosts the photocatalytic degradation of nitrobenzene and methyl orange dye solutions. The multilayer structure of the microcavity was designed to ensure the appearance of optical resonances at the a-TiO2 layer location and wavelengths around the absorption onset of this semiconductor. In this porous 1D Bragg microcavity, the diffusion constraints of molecules through the capping layers covering the a-TiO2 are effectively compensated by an increase in the photocatalytic activity due to the light confinement phenomena. We also report that the absorption coefficient of methyl orange dye solution infiltrated within the pore structure of the microcavity is exalted at the wavelengths of the corresponding optical resonances. This effect gives rise to a small but non-negligible visible light photodegradation of dye molecules. The possibilities of tailoring the design of 1D photonic systems to boost the photocatalytic activity of a-TiO2 are discussed.

June, 2022 · DOI: 10.1021/acsanm.2c00477

Reactividad de Sólidos

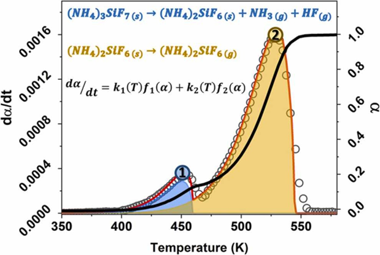

Thermal behavior of ammonium fluorosilicates complexes: Obtaining and kinetic analysis

Resentera, AC; Perejon, A; Esquivel, MR; Perez-Maqueda, LA; Rodriguez, MHChemical Engineering Research amd Design, 182 (2022) 490-501 DOI: 10.1016/j.cherd.2022.04.021

Abstract

In this work, a mixture of (NH4)3SiF7/(NH4)2SiF6 powders was obtained as a by-product of the Li extraction process from alpha-spodumene aluminosilicate with NH4HF2. The thermal behavior of the powders was analyzed by non-isothermal thermogravimetric experiments. The kinetic parameters that describe the processes involved were obtained using mathematical deconvolution, Friedman's method, combined kinetic analysis, and nonlinear regression optimization. The results show that the process occurs in two partially overlapping steps, the thermal decomposition of (NH4)3SiF7 into (NH4)2SiF6 and the subsequent sublimation of (NH4)2SiF6. The apparent activation energies were 72.6 and 79.8 kJ/ mol for steps 1 and 2, respectively. The apparent pre-exponential factors were 1.19 x 106 and 2.50 x 105 s-1, respectively. The kinetic models indicated that Step 1 follows an A2 model, while Step 2 follows an F0 model. Finally, the resulting kinetic parameters allowed the reconstruction of the original experimental curves and obtaining predictions of curves recorded under other heating programs.

June, 2022 · DOI: 10.1016/j.cherd.2022.04.021

Materiales Avanzados

Thermal behaviour of the different parts of almond shells as waste biomass

Garzon, E; Arce, C; Callejon-Ferre, AJ; Perez-Falcon, JM; Sanchez-Soto, PJJournal of Thermal Analysis and Calorimetry, 147 (2022) 5023-5035 DOI: 10.1007/s10973-021-10940-x

Abstract