Scientific Papers in SCI

2019

2019

Materiales Coloidales - Materiales Ópticos Multifuncionales

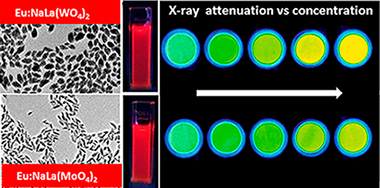

Synthesis, functionalization and properties of uniform europium-doped sodium lanthanum tungstate and molybdate (NaLa(XO4)(2), X = Mo,W) probes for luminescent and X-ray computed tomography bioimaging

Laguna, M; Nunez, NO; Becerro, AI; Lozano, G; Moros, M; de la Fuente, JM; Corral, A; Balcerzyk, M; Ocana, MJournal of Colloid and Interface Science, 554 (2019) 520-530

Show abstract ▽

A one-pot simple procedure for the synthesis of uniform, ellipsoidal Eu3+-doped sodium lanthanum tungstate and molybdate (NaLa(XO4)(2), X = W, Mo) nanophosphors, functionalized with carboxylate groups, is described. The method is based on a homogeneous precipitation process at 120 degrees C from appropriate Na+ Ln(3+) and tungstate or molybdate precursors dissolved in ethylene glycol/water mixtures containing poly acrylic acid. A comparative study of the luminescent properties of both luminescent materials as a function of the Eu3+ doping level has been performed to find the optimum nanophosphor, whose efficiency as X-ray computed tomography contrast agent is also evaluated and compared with that of a commercial probe. Finally, the cell viability and colloidal stability in physiological pH medium of the optimum samples have also been studied to assess their suitability for biomedical applications.

October, 2019 | DOI: 10.1016/j.jcis.2019.07.031

Química de Superficies y Catálisis

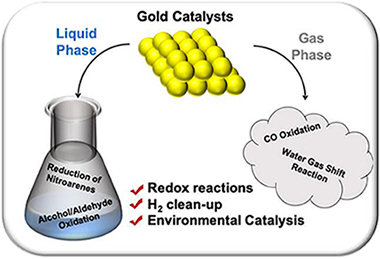

The Success Story of Gold-Based Catalysts for Gas- and Liquid-Phase Reactions: A Brief Perspective and Beyond

Price, CAH; Pastor-Perez, L; Ivanova, S; Reina, TR; Liu, JFrontiers in Chemistry, 7 (2019) 691

Show abstract ▽

Gold has long held the fascination of mankind. For millennia it has found use in art, cosmetic metallurgy and architecture; this element is seen as the ultimate statement of prosperity and beauty. This myriad of uses is made possible by the characteristic inertness of bulk gold; allowing it to appear long lasting and above the tarnishing experienced by other metals, in part providing its status as the most noble metal.

October, 2019 | DOI: 10.3389/fchem.2019.00691

Reactividad de Sólidos

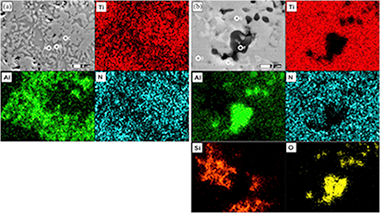

The influence of mechanical activation process on the microstructure and mechanical properties of bulk Ti2AlN MAX phase obtained by reactive hot pressing

Salvo, C; Chicardi, E; Garcia-Garrido, C; Jimenez, JA; Aguilar, C; Usuba, J; Mangalaraja, RVCeramics International, 45 (2019) 17793-17799

Show abstract ▽

The effect of mechanical activation process on the microstructure and mechanical properties of bulk nanostructured Ti2AlN compound has been investigated in this work. The mixture of Ti and AlN powders was prepared in a 2:1 molar ratio, and a part of this powder was subjected to a high-energy milling process under argon atmosphere for 10 h using agate as grinding media. Finally, the densification and formation of the ternary Ti2AlN MAX phase through solid state reaction of both unmilled and milled powders were carried out by hot pressing under 15 or 30 MPa at 1200 degrees C for 2 h. The microstructure of precursor powder mixtures and the consolidated samples was characterized by using X-ray diffraction (XRD) and a scanning electron microscope equipped with an energy dispersive X-ray spectroscopy (SEM/EDS). The X-ray diffraction patterns were fitted using the Rietveld refinement for phase quantification and to determine their most important microstructural parameters. Microstructure and mechanical properties of the consolidated samples were correlated with the load used for the hot pressing process. The substantial increase of hardness, the higher densification and the lower grain sizes observed in the samples prepared from the activated powders were attributed to the formation of second phases like Ti5Si3 and Al2O3.

October, 2019 | DOI: 10.1016/j.ceramint.2019.05.350

Propiedades mecánicas, modelización y caracterización de cerámicos avanzados

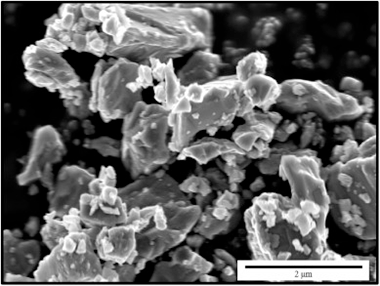

Sintering kinetics, defect chemistry and room-temperature mechanical properties of titanium nitride prepared by spark plasma sintering

Chavez, JMM; Moshtaghioun, BM; Hernandez, FLC; Garcia, DGJournal of Alloys and Compounds, 807 (2019) 151666

Show abstract ▽

Fully dense titanium nitride polycrystals have been prepared by spark plasma sintering. The kinetics of the sintering process and the optimized conditions for SPS processing have been put forward. Microstructural analyses of the resulting samples have unambiguously shown the coexistence of titanium as Ti2+, Ti3+ and Ti4+, thus driving the presence of cation vacancies. This fact is a new ingredient which is shown to influence the mechanical properties of this strategic ceramic.

October, 2019 | DOI: 10.1016/j.jallcom.2019.151666

Reactividad de Sólidos

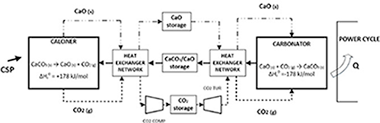

The Calcium-Looping (CaCO3/CaO) process for thermochemical energy storage in Concentrating Solar Power plants

Ortiz, C; Valverde, JM; Chacartegui, R; Perez-Maqueda, LA; Gimenez, PRenewable & Sustanaible Energy Reviews, 113 (2019) 109252

Show abstract ▽

Energy storage based on thermochemical systems is gaining momentum as a potential alternative to molten salts in Concentrating Solar Power (CSP) plants. This work is a detailed review about the promising integration of a CaCO3/CaO based system, the so-called Calcium-Looping (CaL) process, in CSP plants with tower technology. The CaL process relies on low cost, widely available and non-toxic natural materials (such as limestone or dolomite), which are necessary conditions for the commercial expansion of any energy storage technology at large scale. A comprehensive analysis of the advantages and challenges to be faced for the process to reach a commercial scale is carried out. The review includes a deep overview of reaction mechanisms and process integration schemes proposed in the recent literature. Enhancing the multicycle CaO conversion is a major challenge of the CaL process. Many lab-scale analyses carried out show that residual effective CaO conversion is highly dependent on the process conditions and the CaO precursors used, reaching values in a wide range (0.07–0.82). The selection of the optimal operating conditions must be based on materials performance, process integration, technology and economics aspects. Global plant efficiencies over 45% (without considering solar-side losses) show the interest of the technology. Furthermore, the technological maturity and potential of the process is assessed. The direction towards which future works should be headed is discussed.

October, 2019 | DOI: 10.1016/j.rser.2019.109252

- ‹ previous

- 115 of 410

- next ›