Scientific Papers in SCI

2019

2019

Nanotecnología en Superficies y Plasma

Influence of Titanium Oxide Pillar Array Nanometric Structures and Ultraviolet Irradiation on the Properties of the Surface of Dental Implants-A Pilot Study

Leon-Ramos, JR; Diosdado-Cano, JM; Lopez-Santos, C; Barranco, A; Torres-Lagares, D; Serrera-Figallo, MANanomaterials, 9 (2019) 1458

Show abstract ▽

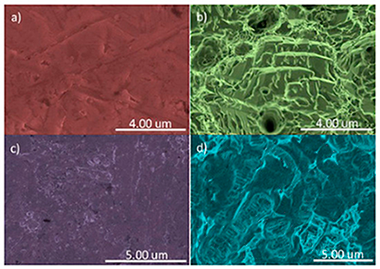

Aim: Titanium implants are commonly used as replacement therapy for lost teeth and much current research is focusing on the improvement of the chemical and physical properties of their surfaces in order to improve the osseointegration process. TiO2, when it is deposited in the form of pillar array nanometric structures, has photocatalytic properties and wet surface control, which, together with UV irradiation, provide it with superhydrophilic surfaces, which may be of interest for improving cell adhesion on the peri-implant surface. In this article, we address the influence of this type of surface treatment on type IV and type V titanium discs on their surface energy and cell growth on them. Materials and methods: Samples from titanium rods used for making dental implants were used. There were two types of samples: grade IV and grade V. In turn, within each grade, two types of samples were differentiated: untreated and treated with sand blasting and subjected to double acid etching. Synthesis of the film consisting of titanium oxide pillar array structures was carried out using plasma-enhanced chemical vapor deposition equipment. The plasma was generated in a quartz vessel by an external SLAN-1 microwave source with a frequency of 2.45 GHz. Five specimens from each group were used (40 discs in total). On the surfaces to be studied, the following determinations were carried out: (a) X-ray photoelectron spectroscopy, (b) scanning electron microscopy, (c) energy dispersive X-ray spectroscopy, (d) profilometry, (e) contact angle measurement or surface wettability, (f) progression of contact angle on applying ultraviolet irradiation, and (g) a biocompatibility test and cytotoxicity with cell cultures. Results: The application of ultraviolet light decreased the hydrophobicity of all the surfaces studied, although it did so to a greater extent on the surfaces with the studied modification applied, this being more evident in samples manufactured in grade V titanium. In samples made in grade IV titanium, this difference was less evident, and even in the sample manufactured with grade IV and SLA treatment, the application of the nanometric modification of the surface made the surface optically less active. Regarding cell growth, all the surfaces studied, grouped in relation to the presence or not of the nanometric treatment, showed similar growth. Conclusions. Treatment of titanium oxide surfaces with ultraviolet irradiation made them change temporarily into superhydrophilic ones, which confirms that their biocompatibility could be improved in this way, or at least be maintained.

October, 2019 | DOI: 10.3390/nano9101458

Química de Superficies y Catálisis

Effect of starch as binder in carbon aerogel and carbon xerogel preparation

Rodriguez, N; Agamez-Pertuz, YY; Romero, E; Diaz-Velasquez, JD; Odriozola, JA; Centeno, MAJournal of Non-Crystalline Solids, 522 (2019) UNSP 119554

Show abstract ▽

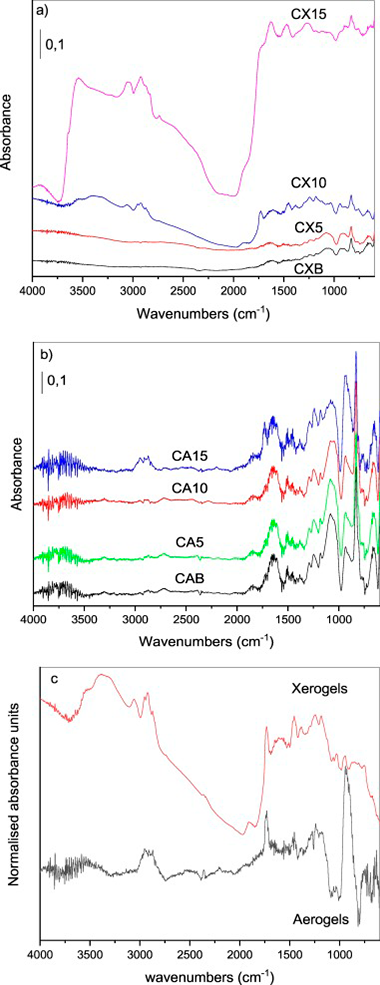

Carbon aerogels and carbon xerogels were synthesized through resorcinol - formaldehyde polycondensation using Na2CO3 as catalyst. The effect of soluble starch introduction in the organic gel preparation on the porous surface properties of these materials was studied. The role of the drying process of the organic gels on the changes in the surface and structural properties of these materials after the addition of soluble starch is discussed. The presence of starch in the prepared carbon xerogels results in the development of microporosity while maintaining the characteristic mesoporosity of carbon xerogels. The Brunauer - Emmett -Teller (BET) surface area increases from 309 m(2)/g in carbon xerogel without soluble starch until 685 m(2)/g when 10% of soluble starch is added. The R- value and average crystallite lattice parameters, inter-layer spacing, crystallite height, crystallite diameter and the average number of aromatic layers per carbon crystallite are discussed in function of drying step and presence of soluble starch. The surface properties were also studied by Raman and DRIFT spectroscopies.

October, 2019 | DOI: 10.1016/j.jnoncrysol.2019.119554

Nanotecnología en Superficies y Plasma

Highly selective few-ppm NO gas-sensing based on necklace-like nanofibers of ZnO/CdO n-n type I heterojunction

Naderi, H; Hajati, S; Ghaedi, M; Espinos, JPSensors and Actuators B-Chemical, 297 (2019) 126774

Show abstract ▽

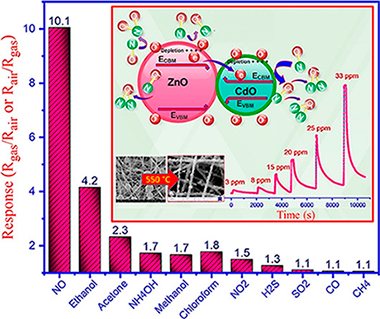

Electrospinning method followed by calcination is applied to synthesize ZnO/CdO nanofibers. Characterization is performed by X-ray diffraction (XRD), scanning electron microscopy (SEM), field emission scanning electron microscopy (FESEM), energy dispersive spectroscopy (EDS), diffuse reflectance spectroscopy (DRS), X-ray photoelectron spectroscopy (XPS), ultraviolet photoelectron spectroscopy (UPS) and reflection electron energy loss spectroscopy (REELS), which resulted in detailed analysis of the sensing material. For instance, it was found that the ZnO/CdO is n-n type I heterojunction which possesses straddling energy band gap, which could affect the mechanism of gas sensing. An electroless gold-plated interdigitated electrode with spacing 200 mu m is fabricated on alumina substrate to host the designed nanofibers being used as gas sensor. Gas-sensing activity of the heterojunction is investigated against NO, NO2, H2S, CH4, SO2 and CO in addition to VOCs such as ethanol, acetone, ammonia, methanol, and chloroform with high selectivity and response to NO gas by monitoring resistance changes. Detailed discussion on the mechanism of sensing is presented. The ZnO/CdO nanofibers are found to be highly sensitive to very low concentration range of NO gas (1.2-33 ppm) at optimal operating temperature of 215 degrees C. The influence of humidity (20-96%) on the sensor response was found to be ignorable. Additionally, good repeatability and long-term stability (45 days, every 5 days, SD = 0.7) was obtained for this sensor. Typically, short response times of 47 and 35 s are obtained versus 3 and 33 ppm of NO, respectively, making our sensor promisingly applicable for monitoring this toxic gas in polluting industries, metropolises and maybe in exhaled breath.

October, 2019 | DOI: 10.1016/j.snb.2019.126774

Fotocatálisis Heterogénea: Aplicaciones

Comparison of the effects generated by the dry-soft grinding and the photodeposition of Au and Pt processes on the visible light absorption and photoactivity of TiO2

Galeano, L; Valencia, S; Marin, JM; Restrepo, G; Navio, JA; Hidalgo, MCMaterials Research Express, 6 (2019) 1050d9

Show abstract ▽

The influence of dry-soft grinding and photodeposition of gold (Au) or platinum (Pt) in the improvement of the photoactivity of TiO2 synthesized by an integrated sol-gel and solvothermal method was studied. TiO2 was modified by a dry-soft grinding process in a planetary ball mill (TiO2(G)). Subsequently, Au or Pt particles were photodeposited in both unmodified TiO2 and TiO2(G) obtaining Au-TiO2, Pt-TiO2, Au-TiO2(G), and Pt-TiO2(G) materials. The photoactivity of the materials was evaluated in the phenol photodegradation under simulated solar radiation. Pt-TiO2 showed the greatest degree of photoactivity improvement in comparison with TiO2 and TiO2-P25. The dry-soft grinding process led to a high photocatalytic activity of TiO2(G) that was similar to Pt-TiO2 activity as consequence of a slight increase in the crystallinity in TiO2(G) due to an additional anatase formation in comparison with TiO2. However, further photocatalytic improvement in TiO2(G) were not achieved with the addition of Au or Pt. Therefore, the dry-soft grinding treatment and noble metal deposition led to similar improvements in the photocatalytic activity of TiO2 for phenol oxidation.

October, 2019 | DOI: 10.1088/2053-1591/ab4316

Nanotecnología en Superficies y Plasma

Antibacterial Nanostructured Ti Coatings by Magnetron Sputtering: From Laboratory Scales to Industrial Reactors

Alvarez, R; Munoz-Pina, S; Gonzalez, MU; Izquierdo-Barba, I; Fernandez-Martinez, I; Rico, V; Arcos, D; Garcia-Valenzuela, A; Palmero, A; Vallet-Regi, M; Gonzalez-Elipe, AR; Garcia-Martin, JMNanomaterials, 9 (2019) art. 1217

Show abstract ▽

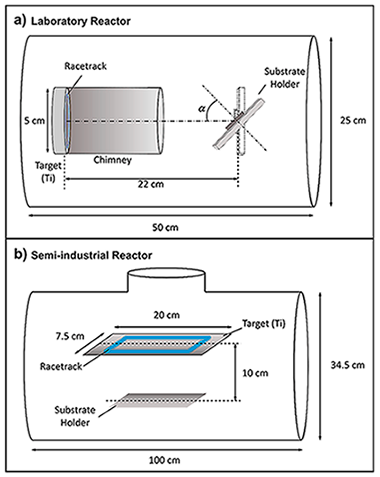

Based on an already tested laboratory procedure, a new magnetron sputtering methodology to simultaneously coat two-sides of large area implants (up to similar to 15 cm(2)) with Ti nanocolumns in industrial reactors has been developed. By analyzing the required growth conditions in a laboratory setup, a new geometry and methodology have been proposed and tested in a semi-industrial scale reactor. A bone plate (DePuy Synthes) and a pseudo-rectangular bone plate extracted from a patient were coated following the new methodology, obtaining that their osteoblast proliferation efficiency and antibacterial functionality were equivalent to the coatings grown in the laboratory reactor on small areas. In particular, two kinds of experiments were performed: Analysis of bacterial adhesion and biofilm formation, and osteoblasts-bacteria competitive in vitro growth scenarios. In all these cases, the coatings show an opposite behavior toward osteoblast and bacterial proliferation, demonstrating that the proposed methodology represents a valid approach for industrial production and practical application of nanostructured titanium coatings.

September, 2019 | DOI: 10.3390/nano9091217

- ‹ previous

- 116 of 410

- next ›