Artículos SCI

2019

2019

Reactividad de Sólidos

The influence of mechanical activation process on the microstructure and mechanical properties of bulk Ti2AlN MAX phase obtained by reactive hot pressing

Salvo, C; Chicardi, E; Garcia-Garrido, C; Jimenez, JA; Aguilar, C; Usuba, J; Mangalaraja, RVCeramics International, 45 (2019) 17793-17799

Show abstract ▽

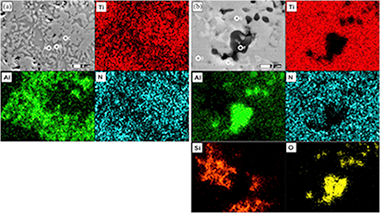

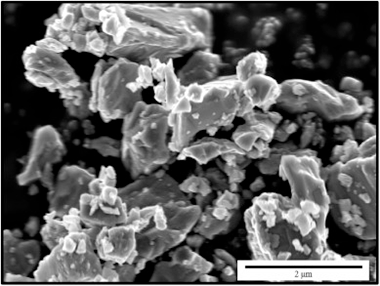

The effect of mechanical activation process on the microstructure and mechanical properties of bulk nanostructured Ti2AlN compound has been investigated in this work. The mixture of Ti and AlN powders was prepared in a 2:1 molar ratio, and a part of this powder was subjected to a high-energy milling process under argon atmosphere for 10 h using agate as grinding media. Finally, the densification and formation of the ternary Ti2AlN MAX phase through solid state reaction of both unmilled and milled powders were carried out by hot pressing under 15 or 30 MPa at 1200 degrees C for 2 h. The microstructure of precursor powder mixtures and the consolidated samples was characterized by using X-ray diffraction (XRD) and a scanning electron microscope equipped with an energy dispersive X-ray spectroscopy (SEM/EDS). The X-ray diffraction patterns were fitted using the Rietveld refinement for phase quantification and to determine their most important microstructural parameters. Microstructure and mechanical properties of the consolidated samples were correlated with the load used for the hot pressing process. The substantial increase of hardness, the higher densification and the lower grain sizes observed in the samples prepared from the activated powders were attributed to the formation of second phases like Ti5Si3 and Al2O3.

Octubre, 2019 | DOI: 10.1016/j.ceramint.2019.05.350

Propiedades mecánicas, modelización y caracterización de cerámicos avanzados

Sintering kinetics, defect chemistry and room-temperature mechanical properties of titanium nitride prepared by spark plasma sintering

Chavez, JMM; Moshtaghioun, BM; Hernandez, FLC; Garcia, DGJournal of Alloys and Compounds, 807 (2019) 151666

Show abstract ▽

Fully dense titanium nitride polycrystals have been prepared by spark plasma sintering. The kinetics of the sintering process and the optimized conditions for SPS processing have been put forward. Microstructural analyses of the resulting samples have unambiguously shown the coexistence of titanium as Ti2+, Ti3+ and Ti4+, thus driving the presence of cation vacancies. This fact is a new ingredient which is shown to influence the mechanical properties of this strategic ceramic.

Octubre, 2019 | DOI: 10.1016/j.jallcom.2019.151666

Nanotecnología en Superficies y Plasma

Antibacterial Nanostructured Ti Coatings by Magnetron Sputtering: From Laboratory Scales to Industrial Reactors

Alvarez, R; Munoz-Pina, S; Gonzalez, MU; Izquierdo-Barba, I; Fernandez-Martinez, I; Rico, V; Arcos, D; Garcia-Valenzuela, A; Palmero, A; Vallet-Regi, M; Gonzalez-Elipe, AR; Garcia-Martin, JMNanomaterials, 9 (2019) art. 1217

Show abstract ▽

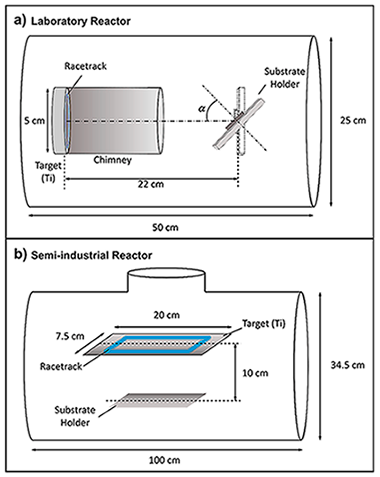

Based on an already tested laboratory procedure, a new magnetron sputtering methodology to simultaneously coat two-sides of large area implants (up to similar to 15 cm(2)) with Ti nanocolumns in industrial reactors has been developed. By analyzing the required growth conditions in a laboratory setup, a new geometry and methodology have been proposed and tested in a semi-industrial scale reactor. A bone plate (DePuy Synthes) and a pseudo-rectangular bone plate extracted from a patient were coated following the new methodology, obtaining that their osteoblast proliferation efficiency and antibacterial functionality were equivalent to the coatings grown in the laboratory reactor on small areas. In particular, two kinds of experiments were performed: Analysis of bacterial adhesion and biofilm formation, and osteoblasts-bacteria competitive in vitro growth scenarios. In all these cases, the coatings show an opposite behavior toward osteoblast and bacterial proliferation, demonstrating that the proposed methodology represents a valid approach for industrial production and practical application of nanostructured titanium coatings.

Septiembre, 2019 | DOI: 10.3390/nano9091217

Materiales de Diseño para la Energía y Medioambiente

Applications and potentialities of Atomic Force Microscopy in fossil and extant plant cuticle characterization

Benitez, JJ; Guzman-Puyol, S; Dominguez, E; Heredia, A; Heredia-Guerrero, JAReview of Palaeobotany and Palynology, 268 (2019) 125-132

Show abstract ▽

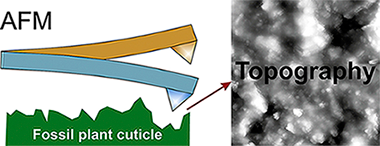

Atomic Force Microscopy (AFM) is a versatile technique of surface characterization, providing accurate information about the topography and other wide variety of magnitudes at submicron scale. It is extensively utilized in materials science, but its use in other disciplines such as paleobotany is infrequent. In this review, we introduce the main concepts of AFM to paleobotanists, comparing the characteristics of this technique to common electronic and optical microscopies. Then, main works with extant plants, in particular plant cuticles, are described. Finally, realistic applications with fossils are reviewed and their potential use in the characterization of plant fossils discussed. AFM is proposed as a complementary technique to common microscopies to characterize plant cuticle fine details at nanoscale.

Septiembre, 2019 | DOI: 10.1016/j.revpalbo.2019.06.015

Nanotecnología en Superficies y Plasma

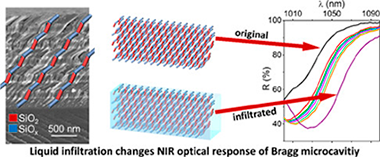

SiOx by magnetron sputtered revisited: Tailoring the photonic properties of multilayers

Garcia-Valenzuela, A; Alvarez, R; Espinos, JP; Rico, V; Gil-Rostra, J; Palmero, A; Gonzalez-Elipe, ARApplied Surface Science, 488 (2019) 791-800

Show abstract ▽

Traditionally porous silicon based photonic structures have been prepared by electrochemically etching of silicon. In this work, porous multilayers of nanocolumnar SiOx and SiO2 thin films acting as near infrared (NIR) 1D-photonic nanostructures are prepared by magnetron sputtering deposition at oblique angles (MS-OA). Simultaneous control of porosity and stoichiometry of the stacked films is achieved by adjusting the deposition angle and oxygen partial pressure according to a parametric formula. This new methodologoy is proved for the synthesis of SiOx thin films with x close to 0.4, 0.8, 1.2, 1.6 and nanostructures varying from compact (at 0 degrees deposition angle) to highly porous and nanocolumnar (at 70 degrees and 85 degrees deposition angles). The strict control of composition, structure and nanostructure provided by this technique permits a fine tuning of the absorption edge and refraction index at 1500 nm of the porous films and their manufacturing in the form of SiOx-SiO2 porous multilayers acting as near infrared (NIR) 1D-photonic structures with well-defined optofluidic responses. Liquid tunable NIR Bragg mirrors and Bragg microcavities for liquid sensing applications are presented as proof of concept of the possibilities of this MS-OA manufacturing method as an alternative to the conventional electrochemical fabrication of silicon based photonic structures.

Septiembre, 2019 | DOI: 10.1016/j.apsusc.2019.05.273

- ‹ anterior

- 118 of 412

- siguiente ›