Scientific Papers in SCI

2022

2022

Materiales de Diseño para la Energía y Medioambiente

Exploring the local environment of the engineered nanoclay Mica-4 under hydrothermal conditions using Eu(3+)as a luminescent probe

Martin-Rodriguez, R; Aguado, F; Alba, MD; Valiente, R; Pavon, E; Perdigon, ACJournal of Alloys and Compounds, 921 (2022) 166086

Show abstract ▽

High charge mica Na4Al4Si4Mg6O20F4 , Mica-4, is a promising candidate as a filling material to immobilize high-level radioactive waste in deep geological repositories due to its extraordinary adsorption capacity. In contrast to traditional clay materials, the structural composition of this mica, with a high content of alu-minum in the tetrahedral sheet, enhances its chemical reactivity, favoring the formation of new crystalline phases under mild hydrothermal conditions, and thus providing a definitive isolation of the radionuclides in the engineered barrier. Moreover, this synthetic clay has some features that allow its use as an optical sensor by doping with luminescent rare earth cations such as Eu3+. In this paper we discuss the local structure of the nanoclay Mica-4 using Eu3+ as a local probe to track the physical and chemical modifica-tions under hydrothermal conditions. For that purpose, a set of hydrothermal experiments has been carried out heating Mica-4 and an aqueous Eu(NO3)(3) solution in a stainless steel reactor at different temperatures and times. Optical properties of the as-treated samples were characterized by spectroscopic measurements. The fine peak structure of emission and the relative intensity of different Eu3+ transitions as well as the luminescence lifetime have been correlated with the structure and composition of this nanoclay, and the interaction mechanisms between the lanthanide ions and the clay mineral at different temperatures and times. Special attention has been paid to understanding the role of the aluminum content, which may act as either an aggregating or dispersing agent, in the optical features and reactivity of the system.

November, 2022 | DOI: 10.1016/j.jallcom.2022.166086

Reactividad de Sólidos

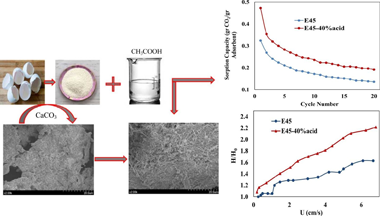

Improvement in cyclic CO2 capture performance and fluidization behavior of eggshell-derived CaCO3 particles modified with acetic acid used in calcium looping process

Imani, M; Tahmasebpoor, M; Sanchez-Jimenez, PE; Valverde, JM; Moreno, VJournal of CO2 Utilization, 65 (2022) 102207

Show abstract ▽

Although calcium-based materials are the most promising adsorbents used in calcium looping process for carbon dioxide removing, their CO2 capture capacity decaying besides poor fluidization, still are the important challenges. In the present investigation, eggshell as a cheap, easily available and unpolluted source of calcium carbonate was used for CO2 capturing in calcium looping process. Eggshell particles were treated with various volume concentrations of acetic acid to improve its sorption capacity. According to the TGA results after 20 carbonation/calcination cycles, the effective carbonation conversion of modified eggshell with 5%, 20%, 30% and 40%. v/v acetic acid was 21.33%, 24.26%, 25.97% and 28.97%, respectively, which is considerable compared to 20.54% for untreated eggshell. The effect of initial eggshell particle size on the adsorption behavior of final adsorbent was also investigated by using two different sizes including dp < 45 mu m and dp > 320 mu m. The results showed that the effective conversion of the adsorbent containing 40%. v/v acetic acid derived from small particle size eggshells was 9.32% higher than that from larger particle size eggshells. In terms of fluidization behavior, surprisingly the addition of acetic acid to the eggshell particles also increased the bed expansion ratio as 8% and 36.2% at gas velocities of 0.27 and 6.67 cm/s, respectively. Further improvement in the fluidity of eggshell modified with 40% acid was performed by manually mixing of SiO2 nanoparticles at different weight percentages. According to the results, adding 7.5 wt% SiO2 leaded to the homogeneous and agglomerate particulate fluidization.

November, 2022 | DOI: 10.1016/j.jcou.2022.102207

Materiales de Diseño para la Energía y Medioambiente

Biopolymer-Based Films Reinforced with FexOy-Nanoparticles

Abdullah, JAA; Jimenez-Rosado, M; Benitez, JJ; Guerrero, A; Romero, APolymers, 14 (2022) 4487

Show abstract ▽

Nowadays, natural polymer-based films are considered potentially environmentally friendly alternatives to conventional plastic films, due to many advantageous properties, including their easy processability, high flexibility, non-toxicity, low cost, high availability, and environmental safety. However, they are limited in their application by a number of shortcomings, including their high water solubility and vapor permeability as well as their poor opacity and low mechanical resistance. Thus, nanoparticles, such as green FexOy-NPs, can be used to overcome the drawbacks associated with these materials. Therefore, the aim of this study was to develop three different polymer-based films (gelatin-based, cellulose acetate-based and chitosan-based films) containing green synthesized FexOy-NPs (1.0% w/w of the initial polymer weight) as an additive to improve film properties. This was accomplished by preparing the different films using the casting method and examining their physicochemical, mechanical, microstructural, and functional characteristics. The results show that the incorporation of FexOy-NPs into the different films significantly enhanced their physicochemical, mechanical, and morphological properties as well as their antioxidant characteristics. Consequently, it was possible to produce suitable natural polymer-based films with potential applications across a wide range of industries, including functional packaging for food, antioxidants, and antimicrobial additives for pharmaceutical and biomedical materials as well as pesticides for agriculture.

November, 2022 | DOI: 10.3390/polym14214487

Materiales de Diseño para la Energía y Medioambiente

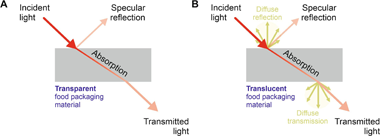

Transparency of polymeric food packaging materials

Guzman-Puyol, Susana; Benitez, Jose J; Heredia-Guerrero, Jose AFood Research International, 161 (2022) 111792

Show abstract ▽

Transparency is a very important technical parameter to evaluate and validate certain food packaging materials. In the recent scientific literature, several methods (i.e. transmittance, opacity, haze, and absorbance) have been used and such variety hinders a direct comparison of results from different authors. In this Review, we describe and discuss the most widely employed methods to measure transparency, with special emphasis on two main parameters: transmittance and opacity. Moreover, a comparison of the different techniques is addressed and the typical values of transmittance and opacity of common transparent food packaging materials are provided. Our current opinion is that transparency should be expressed as transmittance in the visible range due to both the quickness and easiness of the measurement and the standardization of data. This information should be accompanied by the thickness value and a graphical image of the analysed samples for a useful and complete characterization.

November, 2022 | DOI: 10.1016/j.foodres.2022.111792

Materiales de Diseño para la Energía y Medioambiente

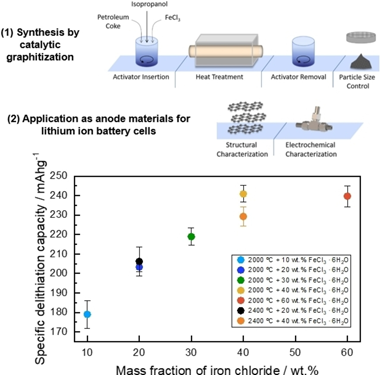

Insights into the Impact of Activators on the 'Catalytic' Graphitization to Design Anode Materials for Lithium Ion Batteries

Hanhart, V; Frankenstein, L; Ramirez-Rico, J; Diozios, V; Winter, M; Gomez-Martin, A; Placke, TChemelectrochem, 9 (2022) e202200819

Show abstract ▽

In this work, we systematically investigate the 'catalytic' graphitization of a biomass precursor (coffee ground) using 10-60 wt.% of the activator iron (III) chloride hexahydrate in a temperature range of 1000 degrees C-2400 degrees C. Special focus is put on the correlation of synthesis conditions, e.g., heat treatment temperature and mass fraction of iron chloride, with the electrochemical performance in carbon vertical bar vertical bar Li metal cells. The structural investigations of the materials reveal a positive impact of an increasing heat treatment temperature and/or mass fraction of inserted activator on the degree of graphitization and the delithiation capacity. However, a saturation point regarding the maximum degree of graphitization at 2000 degrees C and reversible capacity by the 'catalytic' graphitization approach using iron (III) chloride has been found. A maximum degree of graphitization of approximate to 69% could be reached by applying 2000 degrees C and 40 wt.% FeCl3 center dot 6H(2)O, resulting in a reversible capacity of 235 mAh g(-1).

November, 2022 | DOI: 10.1002/celc.202200819

- ‹ previous

- 38 of 410

- next ›