Scientific Papers in SCI

2020

2020

Química de Superficies y Catálisis

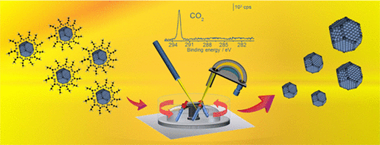

Free-Carbon Surface for PtCu Nanoparticles: An In Situ Near Ambient Pressure X-ray Photoelectron Spectroscopy Study

Castillo, R; Navarro-Jaen, S; Romero-Sarria, F; Perez-Dieste, V; Escudero, C; Centeno, MA; Daturi, M; Odriozola, JAJournal of Physical Chemistry C, 124 (2020) 19046-19056

Show abstract ▽

Usually, nanoparticle synthesis methodologies require the use of organic molecules (capping agent, solvent molecules, etc.), which results in carbon deposits on the nanoparticle surface. These residues modify the surface properties mainly affecting the catalytic behavior. In this work, unsupported poly(vinylpyrrolidone) (PVP)-stabilized PtCu (1:3 molar ratio) bimetallic alloy nanoparticles were synthetized and characterized. An alternative surface cleaning method has been designed, which successfully removes the presence of organic fragments. To address this key issue, we have combined a first nanoparticle washing step with a near ambient pressure X-ray photoelectron spectroscopy (NAPXPS) study in order to obtain a clean active site and the total understanding of the carbon elimination mechanism. The dynamic evolution of the surface organic species composition under different gas mixtures at 750 mTorr and 350 degrees C has been studied, and only under CO2 exposure, NAPXPS analysis revealed a total availability of the active site by the removal of the organic nanoparticle coating.

September, 2020 | DOI: 10.1021/acs.jpcc.0c04713

Nanotecnología en Superficies y Plasma

The wrinkling concept applied to plasma-deposited polymer-like thin films: A promising method for the fabrication of flexible electrodes

Thiry, Damien; Vinx, Nathan; Damman, Pascal; Aparicio, Francisco F.J.; Tessier, Pierre-Yves; Moerman, David; Leclere, Philippe; Godfroid, Thomas; Deprez, Sylvain; Snyders, RonyPlasma Processes and Polymers, 17 (2020) e2000119

Show abstract ▽

In this communication, we report on an innovative solvent-free method that allows for the design of nano-/micropatterns with tuneable dimensions. Our approach is based on the spontaneous wrinkling phenomenon taking place in a bilayer system formed by a mechanically responsive bottom plasma polymer layer and a top aluminum thin film. The dimensions of the wrinkles can be adjusted in a wide range (i.e., from nanometer to micrometer range) by modulating the cross-linking density as well as the thickness of the plasma polymer layer. Finally, it is demonstrated that these wrinkled surfaces could efficiently be used as flexible electrodes. The whole set of our data unambiguously reveals the attractiveness of our method for the fabrication of the micro-/nanopattern with dimensions on demand.

September, 2020 | DOI: 10.1002/ppap.202000119

Reactividad de Sólidos

Synthesis of all equiatomic five-transition metals High Entropy Carbides of the IVB (Ti, Zr, Hf) and VB (V, Nb, Ta) groups by a low temperature route

Chicardi, E; Garcia-Garrido, C; Hernandez-Saz, J; Gotor, FJCeramics International, 46 (2020) 21421-21430

Show abstract ▽

The six possible equiatomic five-transition metal High Entropy Carbides (HECs) of the IVB (Ti, Zr, Hf) and VB (V, Nb, Ta) groups of the periodic table, i.e., TiZrHfVNbC5, TiZrHfVTaC5, TiZrHfNbTaC5, TiZrVNbTaC5, TiHfVNbTaC5 and ZrHfVNbTaC5, were successfully obtained via a powder metallurgy route at room temperature, specifically, by one-step diffusion mechanosynthesis starting from the elemental constituents (using graphite as the carbon source). Three of those HECs, TiZrHfVTaC5, TiZrVNbTaC5 and ZrHfVNbTaC5, were developed for the first time. Their development was possible without any subsequent thermal treatment, in contrast to the usual way (reactive sintering at 1800-2200 degrees C), and in a powder form, make them potential advanced raw ceramics for hard, refractory and oxidation resistance coatings or matrix phase composites.

September, 2020 | DOI: 10.1016/j.ceramint.2020.05.240

Química de Superficies y Catálisis

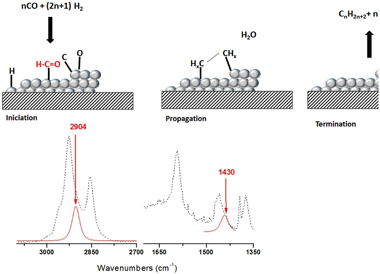

Experimental evidence of HCO species as intermediate in the fischer tropsch reaction using operando techniques

Diaz-Sanchez, RM; de-Paz-Carrion, A; Serrera-Figallo, MA; Torres-Lagares, D; Barranco, A; Leon-Ramos, JR; Gutierrez-Perez, JLApplied Catalysis B-Environmental, 272 (2020) 119032

Show abstract ▽

Fischer Tropsch's reaction, known from 1925, receives special attention nowadays due to its key role in the CO2 or biomass valorization to liquid fuels and chemicals. Several aspects on the exact mechanism or the role of water in this reaction are not yet completely clear. Formyl species, HCO, have been proposed as the most probable reaction intermediate, but they have never been observed under operation conditions closed to the real ones. In this work, using DRIFTS-MS operando techniques, HCO intermediates are detected under a H2/CO flow and 200 °C. IR bands at 2900 cm−1 and 1440 cm−1 attributed to ν(C–H) and δ(HCO) vibrations modes characterize these species. Evolution of these bands with the reaction time evidences its high reactivity with OH groups, which explains the positive effect of water on the CO conversion previously observed.

September, 2020 | DOI: 10.1016/j.apcatb.2020.119032

Materiales de Diseño para la Energía y Medioambiente

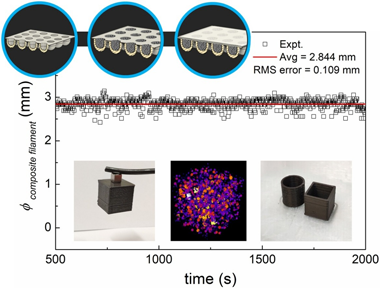

Novel procedure for laboratory scale production of composite functional filaments for additive manufacturing

Diaz-Garcia, A; Law, JY; Cota, A; Bellido-Correa, A; Ramirez-Rico, J; Schafer, R; Franco, VMaterials Today Communications, 24 (2020) 101049

Show abstract ▽

Successful 3D printing by material extrusion of functional parts for new devices requires high quality filaments. Uniform homogeneity and good dispersion of particles embedded in filaments typically takes several cycles of extrusion or well-prepared feedstock by injection molding, industrial kneaders or twin-screw compounding. These methods need specific production devices that are not available in many laboratories non-specialized in polymer research, such as those working on different material science and technology topics that try to connect with additive manufacturing. Therefore, laboratory studies are usually limited to compositions and filler concentrations provided by commercial companies. Here, we present an original laboratory scale methodology to custom-prepare the feedstock for extruding magnetic composite filaments for fused filament fabrication (FFF), which is attainable by a desktop single-screw extruder. It consists in encapsulating the fillers in custom made capsules that are used as feedstock and reach the melting area of the extruder maintaining the same concentration of fillers. Results have shown that our approach can create smooth and continuous composite filaments with good homogeneity and printability with fine level of dimensional control. We further show the good dispersion of the particles in the composite filament using X-Ray Tomography, which enabled a 3D reconstruction of the spacial distribution of the embedded magnetic particles. The major advantage of this new way of preparing the composite feedstock is that it avoids the hassle of multiple extrusion runs and industrial machinery, yet providing uniform filaments of well controlled filler concentration, which is predictable and reproducible. The proposed methodology is suitable for different polymer matrices and applicable to other functional particle types, not just limited to magnetic ones. This opens an avenue for further laboratory scale development of novel functional composite filaments, useful for any community. This democratization of complex filament preparation, including consumers preparing their own desired uniform novel filaments, will facilitate to unify efforts nearing 3D printing of new functional devices.

September, 2020 | DOI: 10.1016/j.mtcomm.2020.101049

- ‹ previous

- 94 of 410

- next ›