Scientific Papers in SCI

2020

2020

Nanotecnología en Superficies y Plasma

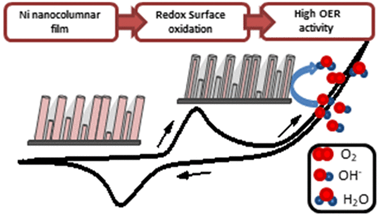

Chemistry and Electrocatalytic Activity of Nanostructured Nickel Electrodes for Water Electrolysis

Lopez-Fernandez, E; Gil-Rostra, J; Espinos, JP; Gonzalez-Elipe, AR; Consuegra, AD; Yubero, FACS Catalysis, 10 (2020) 6159-6170

Show abstract ▽

Herein we have developed nanostructured nickel-based electrode films for anion exchange membrane water electrolysis (AEMWE). The electrodes were prepared by magnetron sputtering (MS) in an oblique angle configuration and under various conditions aimed at preparing metallic, oxide, or oxyhydroxide films. Their electrochemical analysis has been complemented with a thorough physicochemical characterization to determine the effect of microstructure, chemical state, bilayer structure, and film thickness on the oxygen evolution reaction (OER). The maximum electrocatalytic activity was found for the metallic electrode, where analysis by X-ray photoelectron spectroscopy (XPS) and X-ray absorption spectroscopy (XAS) demonstrated that the active catalytic phase at the surface after its electrochemical conditioning is a kind of oxidized nickel oxide/hydroxide layer with the thickness of a few nanometers. Electrochemical impedance spectroscopy analysis of these steady-state working electrodes supports that the enhanced performance of the metallic nickel anode vs other chemical states resides in the easier electron transfer through the electrode films and the various interlayers built up during their fabrication and activation. The long-term steady-state operation of the anodes and their efficiency for water splitting was proved in a full-cell AEMWE setup incorporating magnetron-sputtered metallic nickel as the cathode. This work proves that MS is a suitable technique to prepare active, stable, and low-cost electrodes for AEMWE and the capacity of this technique to control the chemical state of the electrocatalytically active layers involved in the OER.

June, 2020 | DOI: 10.1021/acscatal.0c00856

Química de Superficies y Catálisis

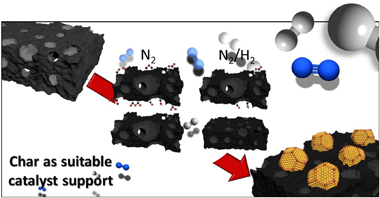

Reductant atmospheres during slow pyrolysis of cellulose: First approach to obtaining efficient char -based catalysts in one pot

Santos, JL; Centeno, MA; Odriozola, JAJournal of Analytical and Applied Pyrolysis, 148 (2020) 104821

Show abstract ▽

Char based metallic (Pd-Au-Ru-Pt/C) catalysts have drawn increasing research interest due to their versatility in biomass related industrial reactions. Recent studies dealing with the synthesis of char-based catalysts in one single step (one-pot) use reductant atmospheres for biomass pyrolysis. In this work, the influence of the use of a reductant N2/H2 atmosphere on the physicochemical properties of the resulting chars was evaluated in comparison with the use of an inert N2 atmosphere. Specifically, the fundamental parameter of the pyrolysis process, the temperature, was evaluated in the 500−900 °C range. Produced chars were fully characterized by N2 isotherms, ultimate CHNS analysis, X-ray Diffraction, Raman spectroscopy, Diffuse Reflectance Infrared spectroscopy, X-ray Photoelectron spectroscopy, helium Temperature Programmed Decomposition and Isoelectric Point analysis. Slow pyrolysis under reductant atmosphere favours deoxygenation reaction against dehydrogenation ones, reduces the carbon yield and results in chars with a more hydrophobic and graphitic character, higher thermal stability and weak surface functionalization. The use of intermediates temperatures (700 °C) favours the obtaining of chars with suitable physicochemical properties and good surface functionalization, which will facilitate the anchoring of the active phase on the surface, improving the metallic dispersion of the resulting one pot catalyst. This leads us to affirm that the use of reducing atmospheres at intermediate temperatures, is superior to the use of inert atmospheres for this purpose. This analysis on the impact of the use of a reductant atmosphere during slow pyrolysis of microcrystalline cellulose opens a new working path for the optimization of char-based catalysts obtained in a single stage.

June, 2020 | DOI: 10.1016/j.jaap.2020.104821

Química de Superficies y Catálisis

Cost-effective routes for catalytic biomass upgrading

Jin, W; Pastor-Perez, L; Yu, J; Odriozola, JA; Gu, S; Reina, TRCurrent Opinion in Green and Sustainable Chemistry, 23 (2020) 1-9

Show abstract ▽

Catalytic hydrodeoxygenation (HDO) is a fundamental and promising route for bio-oil upgrading to produce petroleum-like hydrocarbon fuels or chemical building blocks. One of the main challenges of this technology is the demand of high-pressure H-2, which poses high costs and safety concerns. Accordingly, developing cost-effective routes for biomass or bio-oil upgrading without the supply of commercial H-2 is essential to implement the HDO at commercial scale. This article critically reviewed the very recent studies relating to the novel strategies for upgrading the biofeedstocks with 'green' H-2 generated from renewable sources. More precisely, catalytic transfer hydro-genation/hydrogenolysis, combined reforming and HDO, combined metal hydrolysis and HDO, water-assisted in-situ HDO and nonthermal plasma technology and self-supported hydrogenolysis are reviewed herein. Current challenges and research trends of each strategy are also proposed aiming to motivate further improvement of these novel routes to become competitive alternatives to conventional HDO technology.

June, 2020 | DOI: 10.1016/j.cogsc.2019.12.008

Materiales de Diseño para la Energía y Medioambiente

New biomorphic filters to face upcoming particulate emissions policies: A review of the FIL-BIO-DIESEL project

Orihuela, MP; Chacartegui, R; Martinez-Fernandez, JEnergy, 201 (2020) 117577

Show abstract ▽

With a high number of diesel vehicles worldwide, particulate emission control is an urgent issue with a global impact, from the health of citizens to commercial future of this technology in some transport segments. Particulate filters are widely used in automotive engines to comply emissions regulations, but current technologies have room for improvement as they add additional backpressure in the exhaust system, and efficient on-board regeneration process is challenging.

The Fil-Bio-Diesel Project is a R&D initiative to improve current particle filtration systems, based on the development of novel biomorphic substrates. By replicating the biologic tissue of a wood precursor, a biomorphic silicon carbide with hierarchic orthotropic microstructure can be produced. The porosity, the pore size, and pore orientation of this bioceramic material can be tailored through the selection of a suitable precursor, widening the initially narrow relationship between filtration efficiency and pressure drop that characterizes granular ceramic materials. In this paper the methodology and main results of the Fil-Bio-Diesel Project are presented. This work shows the peculiar advantages of biomorphic silicon carbide through several experimental studies. The results show the potential of this novel filter substrate to be used in future particulate abatement systems.

June, 2020 | DOI: 10.1016/j.energy.2020.117577

Química de Superficies y Catálisis

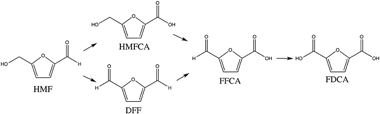

5-Hydroxymethyl-2-Furfural Oxidation Over Au/Ce(x)Zr(1-x)O(2)Catalysts

Megias-Sayago, C; Bonincontro, D; Lolli, A; Ivanova, S; Albonetti, S; Cavani, F; Odriozola, JAFrontiers in Chemistry, 8 (2020) 461

Show abstract ▽

A series of gold catalysts supported on pure CeO2, ZrO2, and two different Ce-Zr mixed oxides have been prepared and tested in the 5-hydroxymethyl-2-furfural oxidation reaction. All catalysts show high catalytic activity (100% conversion) and important selectivity (27-41%) to the desired product i.e., 2,5-furandicarboxylic acid at low base concentration. Products selectivity changes with the support nature as expected, however, the observed trend cannot be related neither to gold particle size, nor to catalyst reducibility and oxygen mobility. An important relation between the FDCA selectivity and the support textural properties is observed, conducing to the general requirement for optimal pore size for this reaction.

June, 2020 | DOI: 10.3389/fchem.2020.00461

- ‹ previous

- 98 of 410

- next ›