Scientific Papers in SCI

2020

2020

Química de Superficies y Catálisis

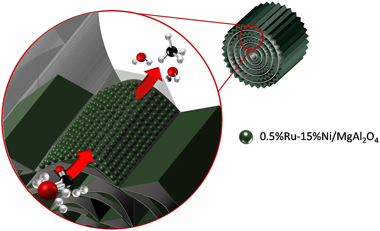

Ru-Ni/MgAl2O4 structured catalyst for CO2 methanation

Navarro, Juan C.; Centeno, Miguel A.; Laguna, Oscar H.; Odriozola, Jose A.Renewabel Energy, 161 (2020) 120-132

Show abstract ▽

Novel catalytic systems should be tested for the valorization of CO2 through the Sabatier reaction, since this process is gaining great importance within strategic sectors of the chemical industry. Therefore, this work explores the feasibility of structuring a catalyst (0.5%Ru-15%Ni/MgAl2O4) for CO2 methanation using metal micromonoliths. The coating of the catalyst over the surface of the micromonoliths is carried out by means of the washcoating procedure and different characterization techniques are applied to establish possible changes in the catalyst during structuring.

Regarding the performance in the Sabatier reaction, the structured systems are tested as well as the powder catalyst in order to establish the possible effects of the structuring processes. For this, variables such as catalyst loading, space velocity, inclusion of water in the feed-stream and the pressurization of the process were studied.

In general, the structuring of the proposed catalyst by the reported procedure is absolutely feasible. There are no substantial changes in the main features of the catalyst and this means that its catalytic performance is not altered after the structuring process either. Furthermore, the structured system exhibits high stability in a long-term test and is comparable with other CO2 methanation catalysts reported in research to date.

December, 2020 | DOI: 10.1016/j.renene.2020.07.055

Nanotecnología en Superficies y Plasma

Wetting and spreading of liquid lithium onto nanocolumnar tungsten coatings tailored through the topography of stainless steel substrates

Munoz-Pina, S; Garcia-Valenzuela, A; Oyarzabal, E; Gil-Rostra, J; Rico, V; Alcala, G; Alvarez, R; Tabares, FL; Palmero, A; Gonzalez-Elipe, ARNuclear Fusion, 60 (2020) 126033

Show abstract ▽

The use of liquid metal as an alternative to cover the plasma-exposed areas of fusion reactors has called for the development of substrates where refilling and metal spreading occur readily and at reasonably low temperatures. In the search for common materials for this purpose, we show that nanostructured tungsten coatings deposited on stainless steel (SS) by magnetron sputtering at oblique angles (MS-OAD) is a good option, provided that the surface microstructure of substrate is properly engineered. Tungsten thin films with nominal thicknesses of 500 and 2500 nm were deposited onto SS plates subjected to conventional surface finishing treatments (sand blasting, sand paper abrasion and electrochemical polishing) to modify the surface topography and induce the appearance of different groove patterns. In the first part of this work we show how the topographical features of the SS substrates affect the typical nanocolumnar microstructure of OAD thin films of tungsten. Subsequently, we characterize the spreading behavior of liquid lithium onto these tungsten nanocolumnar surfaces and critically discuss whether nanocolumnar tungsten thin films are a suitable option for the wetting and spreading of molten lithium. As a result, we reveal that the features of the tungsten nanocolumnar coating, characterized by a given height and void spaces between nanocolumns in the order of 1–2 μm, is critical for the spreading of molten lithium, while the existence of wider channels affects it very weakly. Moreover, it is shown that tungsten films deposited by MS-OAD on SS substrates subjected to conventional finishing procedures represent a good alternative to other more complex surface engineering procedures utilized for this purpose.

December, 2020 | DOI: 10.1088/1741-4326/abb53e

Materiales Avanzados

Characterization, thermal and ceramic properties of phyllite clays from southeast Spain

Garzon, Eduardo; Perez-Villarejo, Luis; Sanchez-Soto, Pedro J.Journal of Thermal Analysis and Calorimetry, 142 (2020) 1659-1670

Show abstract ▽

The present research studied a set of phyllite clays from several deposits in southeast Spain. These phyllite clays have traditionally been used as sealing material to impermeabilize roofs, embankments, ponds, construction and waste landfill, with recent applications in the preparation of new mortars. However, studies on thermal behaviour and ceramic properties of phyllite clays have been scarce. The present research showed a summary of previous characterization studies on representative phyllite clays from these deposits with additional results. Mineralogical, by X-ray diffraction, and chemical, by X-ray fluorescence characterization of these samples were summarized. Thermal analysis methods (DTA-TG and thermal diffractometry) were applied to achieve a more complete mineralogical characterization. Several phyllite clay samples were selected for a ceramic study by firing pressed powdered samples up to 1300 degrees C. Sintered or vitrified materials, with porosities almost zero, were obtained from these phyllite clays after firing at 1100-1200 degrees C, with apparent densities between 2.1 and 2.4 g cm(-3). Higher firing temperatures (> 1250 degrees C) produced deformation and expansion of the ceramic bodies. These results allowed obtain the vitrification temperature (T-v) and the temperature of the maximum bulk density (T-d). According to the previous mineralogical and chemical characterization and the values of these parameters, the phyllite clay samples were classified in three varieties, as follows: (1)Micaceous, characterized by predominant layer silicates, mainly muscovite or illite, alkaline elements (mainly K2O higher than 3.5 mass%) and lower values of both T(v)and T-d, (2)Quartzitic, with predominant quartz and SiO(2)and intermediate values of T(v)and T-d, and (3)Carbonaceous, characterized by predominant dolomite, medium contents of CaO and MgO and higher values of both T(v)and T-d. These results are interesting for the application of these phyllite clays as ceramic raw materials.

December, 2020 | DOI: 10.1007/s10973-020-10160-9

Nanotecnología en Superficies y Plasma

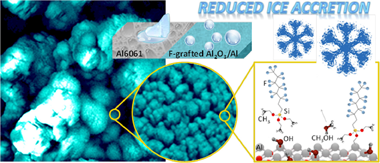

Robust anti-icing superhydrophobic aluminum alloy surfaces by grafting fluorocarbon molecular chains

Rico, V; Mora, J; Garcia, P; Aguero, A; Borras, A; Gonzalez-Elipe, AR; Lopez-Santos, CApplied Materials Today, 21 (2020) 100815

Show abstract ▽

Infusion of low surface tension liquids in nanostructured surfaces is currently used to promote an anti icing response, although the long term stability of these systems is often jeopardized by losses of the infused liquid. In this work, we propose an alternative to the infusion procedure to induce a more effective and long lasting anti-icing capacity. The method consists of a combination of surface nanostructuration with the chemical grafting of fluorocarbon molecules. Al6061 substrates have been subjected to laser roughening and further modified with a nanostructured Al2O3 thin film to achieve a dual roughness and porous surface state. These surfaces have been subjected to a grafting treatment with perfluorooctyltriethoxysilane (PFOTES) vapor or, for comparative purposes, infused with a low surface tension liquid. A comparative analysis of the wetting, water condensation and anti-icing properties of these two systems showed an outstandingly better performance for the grafted surfaces with respect to the infused ones. Grafted surfaces were markedly superhydrophobic and required higher water vapor pressures to induce condensation. When looking for their anti-icing capacity, they presented quite long freezing delay times for supercooled water droplets (i.e. almost four hours) and exhibited a notably low ice accretion in a wind tunnel test. The high aging resistance and durability of these grafted surfaces and the reproducibility of the results obtained when subjected to successive ice accretion cycles show that molecular grafting is an efficient anti-icing methodology that, in aggressive media, may outperform the classical infusion procedures. The role of the fluorocarbon chains anchored on the surface in inducing an anti-icing functionality is discussed.

December, 2020 | DOI: 10.1016/j.apmt.2020.100815

Materiales Avanzados

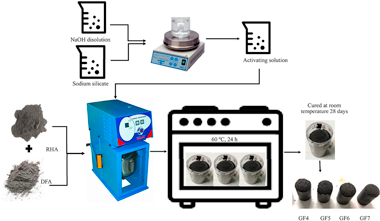

Dust filter of secondary aluminium industry as raw material of geopolymer foams

Eliche-Quesada, D; Ruiz-Molina, S; Perez-Villarejo, L; Castro, E; Sanchez-Soto, PJHournal of Building Engineering, 32 (2020) 101656

Show abstract ▽

In this work, the use of waste dust filter of secondary aluminum industry (DFA) to obtain geopolymer foams has been studied. The waste was used as source of alumina and foaming agent. As precursor and principal reactive silica supplier rice husk ash was used. Precursors were chemically activated by means of a sodium hydroxide aqueous solution and a commercial sodium silicate solution. The influence of the DFA content or Si/Al molar ratio (4-7) were determined by keeping the Si/Na molar ratio of 0.7 M constant and the concentration of sodium hydroxide in the activating solution equal to 8.5 M. The geopolymer foams obtained were studied by X-ray Diffraction (XRD), adsorption/desorption of nitrogen, infrared spectroscopy (FTIR), and scanning electron microscope (SEM) techniques. The results indicated that geopolymer foams presented low values of bulk density (643-737 kg/m(3)) high values of apparent porosity (62-70%), low, but sufficient values of compressive strength (0.5-1.7 MPa) and good values of thermal conductivity (0.131-0.157 W/mK). Lower values of thermal conductivity were obtained for Si/Al = 4 and 5 M ratios, due to the highest apparent porosity and the highest total pore volume. These geopolymer foam materials have similar properties to other construction materials sector such as gypsum boards, foamed concrete, or insulating materials. In addition, its use in other applications of interest such as catalyst support or gas filtration materials could be investigated.

November, 2020 | DOI: 10.1016/j.jobe.2020.101656

- ‹ previous

- 90 of 410

- next ›